01-03-2018: Sciaky announced record-breaking sales of large-format 3D printers based on EBAM technology

The company sold 4 machines for the aerospace industry, as well as large parts for military vehicles and ships

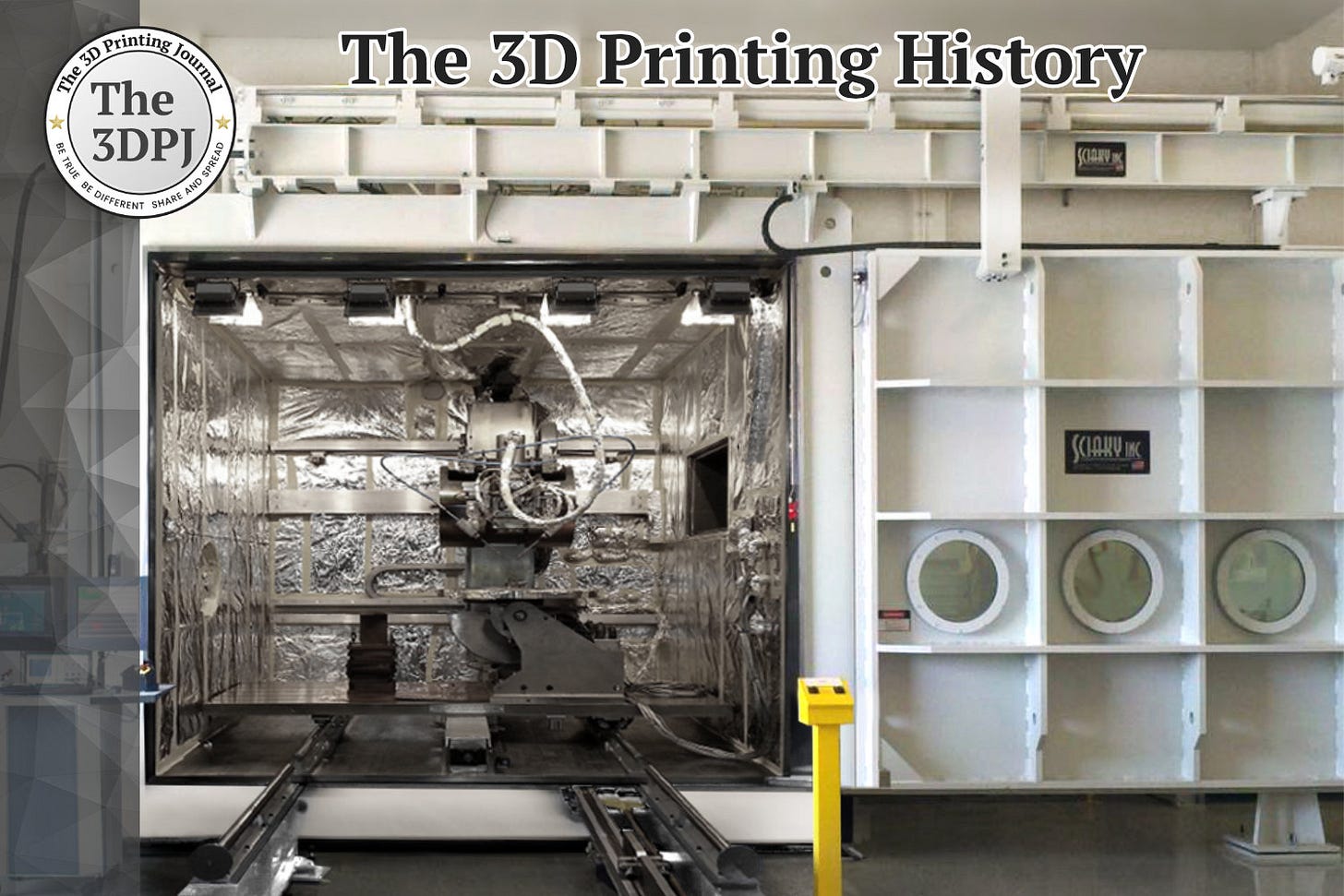

On January 3, 2018, Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI), announced that in December 2017, it had achieved record sales of its EBAM systems. The company sold four machines to be used for printing titanium structures for the aerospace industry, as well as large parts for military vehicles and ships. Three of the machines were EBAM 110 models, while the fourth was an EBAM 150, capable of printing the largest metal components with dimensions up to 3708 mm x 1575 mm x 1575 mm. All units were scheduled for delivery by mid-2018.

Although this news might not seem groundbreaking in the context of 3D printing history, I saw it as an excellent opportunity to highlight one of the most intriguing and innovative companies in the AM industry, especially in its most challenging and demanding sectors—namely aerospace and defense.

Sciaky is a leader in large-format metal additive manufacturing. Founded in 1939, the company initially focused on electron beam welding (EBW) systems for the aerospace, defense, and energy sectors. In the mid-1990s, Sciaky introduced its groundbreaking Electron Beam Additive Manufacturing (EBAM) technology. This technology is distinguished by its ability to produce the largest-scale parts, ranging from 203 mm to 5.79 meters in length. Sciaky’s systems also feature the fastest metal deposition rates in the industry, achieving speeds of 3.18 to 18.14 kg per hour.

The company’s proprietary IRISS (Interlayer Real-time Imaging & Sensing System) ensures real-time control of the printing process, guaranteeing consistency in geometry, mechanical properties, and chemical composition.

The 2018 sale of four systems might not seem particularly impressive to those unfamiliar with Sciaky, but even today, such a sales figure would be noteworthy. First, these machines cost millions of dollars. Second, they are highly specialized systems catering to a relatively small customer base.

Sciaky’s EBAM 3D printers are capable of working with a wide range of materials, including titanium, tantalum, niobium, tungsten, Inconel, and stainless steel. The systems are versatile, supporting both the creation of entirely new parts and the repair of existing components.

The most significant attribute of Sciaky’s machines is their exceptionally large build volumes, especially for additive manufacturing. The EBAM 110 model allowed for parts with maximum dimensions of 1.77 x 1.19 x 1.6 meters and the repair of components up to 2.69 x 1.19 x 1.6 meters. The EBAM 115 model offered an even larger build area, with dimensions of 2.7 x 1.5 x 1.5 meters.

Sciaky’s machines are used by clients in the aerospace and defense sectors for producing aircraft components, military ground vehicles, and naval vessels.

Source: www.sciaky.com