01-21-2022: Eplus3D introduced a large-format metal 3D printer capable of producing parts over one meter in size

It was the largest in the company's portfolio and one of the largest available worldwide

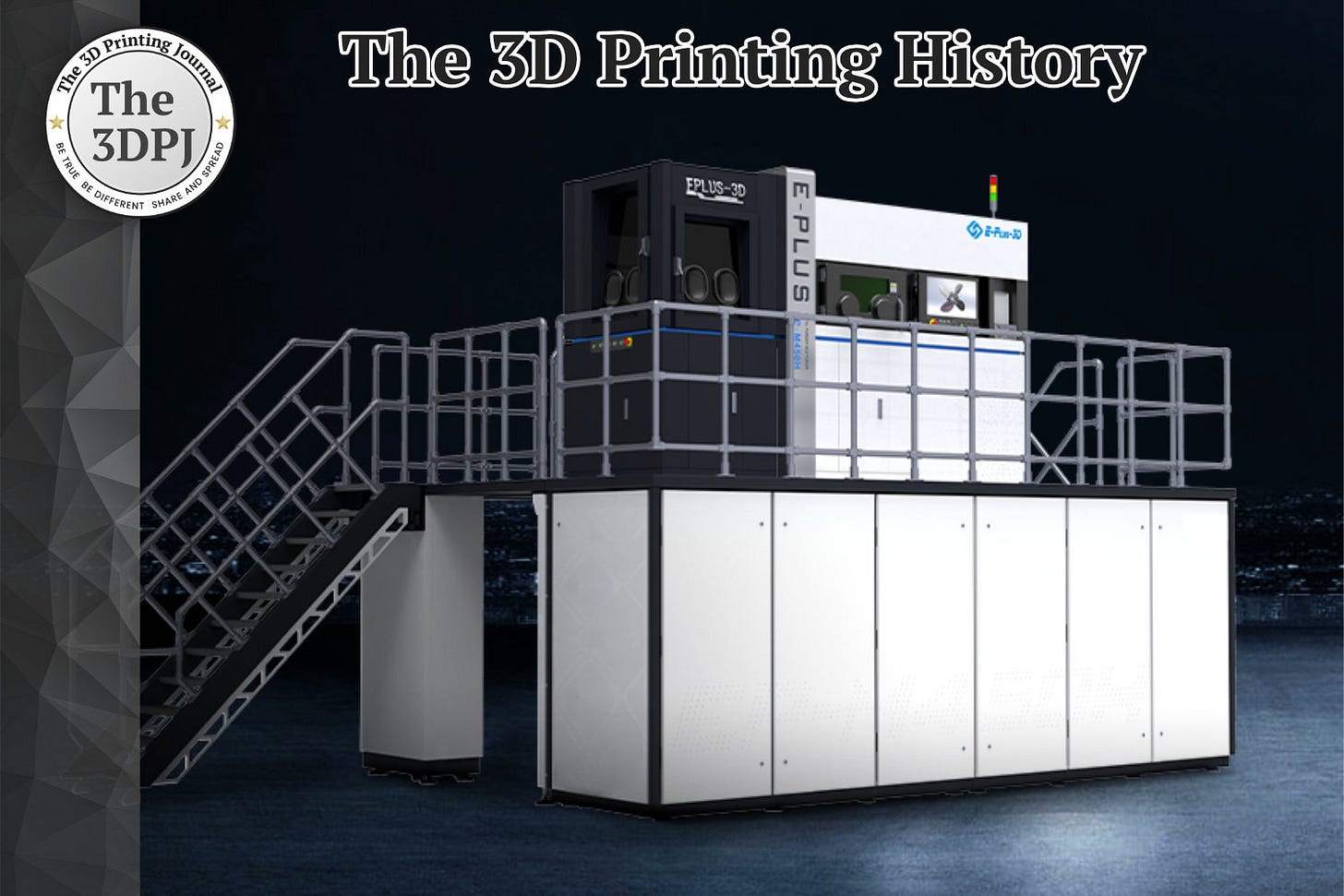

On January 21, 2022, Eplus3D announced the launch of the EP-M450H metal 3D printing system, which was the largest in the company's portfolio and one of the largest available worldwide. The 3D printer featured a build volume of 455 x 455 x 1100 mm, equivalent to over 200 liters of capacity. The machine was designed to 3D print large, high-performance parts for industries such as aerospace, automotive, and defense.

Eplus3D was founded in 2014 as a subsidiary of Shining3D, one of the world’s largest manufacturers of 3D scanners. In September 2021, the companies decided to formally separate, allowing Eplus3D to focus entirely on producing industrial MPBF (Metal Powder Bed Fusion) and PPBF (Polymer Powder Bed Fusion) machines, which correspond to SLM and SLS technologies, respectively.

The EP-M450H 3D printer was equipped with a 500 W fiber laser and offered an optional dual-laser configuration, which provided a 70% increase in 3D printing efficiency. With a scanning speed of up to 8 m/s, the EP-M450H achieved a maximum build rate of 55 cm³/h. Additionally, the manufacturer claimed the printer could achieve part densities exceeding 99.9% and mechanical property deviations below 5%. The EP-M450H also featured an optimized gas flow design to effectively remove smoke and spatter, ensuring uniform and consistent 3D printing results.

On the software side, the printer allowed users to apply different process parameters to various sections of a model. For instance, parts could be divided into upper and lower surfaces or into core and small areas, with customized settings for each. The system was complemented by Eplus3D’s proprietary EP-Hatch processing software, which enabled users to leverage optimized scanning strategies to reduce printing time. Additionally, the software could be integrated with Siemens NX to enhance production efficiency.

The EP-M450H 3D printer was compatible with a wide range of metal powders, including titanium alloys, stainless steel, maraging steel, aluminum alloys, nickel alloys, cobalt-chrome, and copper alloys.

Source: www.eplus3d.com