02-02-2004: Adrian Bowyer launched the RepRap Project

It was a pivotal moment in 3D printing history that 5 years later led to the birth of desktop-grade 3D printers market and industry

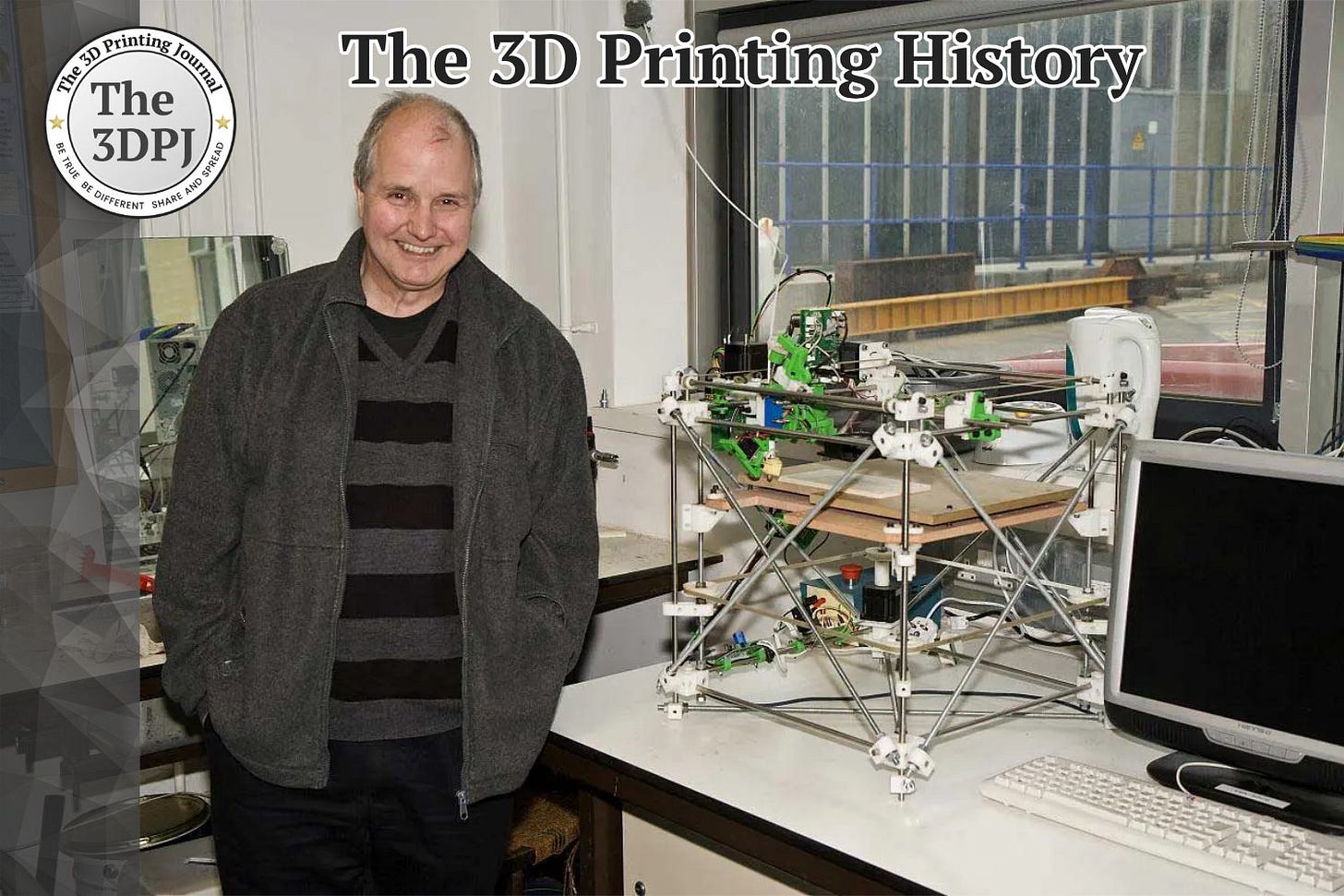

On February 2, 2004, the RepRap project was initiated—one of the key milestones in the history of 3D printing. On that day, Adrian Bowyer, a British engineer and lecturer at the University of Bath, published the concept of a self-replicating 3D printing machine. The RepRap project (short for “Replicating Rapid Prototyper”) aimed to create a 3D printer capable of producing most of its own components, paving the way for the mass replication of such devices. It was a revolutionary idea that aligned with the open-source movement and sought to democratize 3D printing technology.

Bowyer’s idea emerged in the context of growing interest in rapid prototyping technologies, which at the beginning of the 21st century were expensive and primarily accessible to large companies and research institutions. He saw the potential in developing an affordable, open-source 3D printer that could be used by anyone. His vision was that the machine would be able to manufacture its own parts, allowing for self-replication and easy distribution.

Before launching the RepRap project, Adrian Bowyer was already an esteemed scientist and engineer. He graduated from Imperial College London and later became a lecturer at the University of Bath, specializing in mechanical engineering and manufacturing technologies. His interest in 3D printing technology stemmed from a desire to make it more accessible and affordable. Bowyer was also a strong advocate of the open-source philosophy, which was crucial for the success of RepRap. He decided to release all plans, instructions, and software related to the project for free, enabling a global community of enthusiasts to develop and refine the technology.

The first version of the RepRap printer, called Darwin, was introduced in 2007. It was a machine capable of printing most of its own parts, except for electronic and metal components. Darwin became the foundation for subsequent iterations, such as Mendel and Huxley. Thanks to its open-source licensing, the RepRap project quickly gained popularity among hobbyists, engineers, and entrepreneurs, who started creating their own 3D printer versions based on Bowyer’s original designs.

Several notable figures were involved in this project, including Zach "Hoeken" Smith—one of the founding members of the RepRap Research Foundation. Smith was among the first in the U.S. to offer parts for 3D printer assembly kits, and in 2009, he co-founded MakerBot Industries. Another key figure was Josef Průša from the Czech Republic, who developed Prusa Mendel based on the Mendel design, which later evolved into the popular Prusa 3D printer series (i2, i3, MK4). The project also involved Dutch engineers Martijn Elserman, Erik de Bruijn, and Siert Wijnia, who went on to establish Ultimaker in 2011.

However, the RepRap project was not the only initiative of its kind. In parallel, starting in 2006, the Fab@Home project was being developed, led by Cornell University students Evan Malone and Hod Lipson. This project also included Maxim Lobovsky, who later co-founded Formlabs.

Source: www.reprap.org