02-13-2019: Airbus announced the selection of Ultimaker as its main 3D printer supplier for its production facilities in Europe

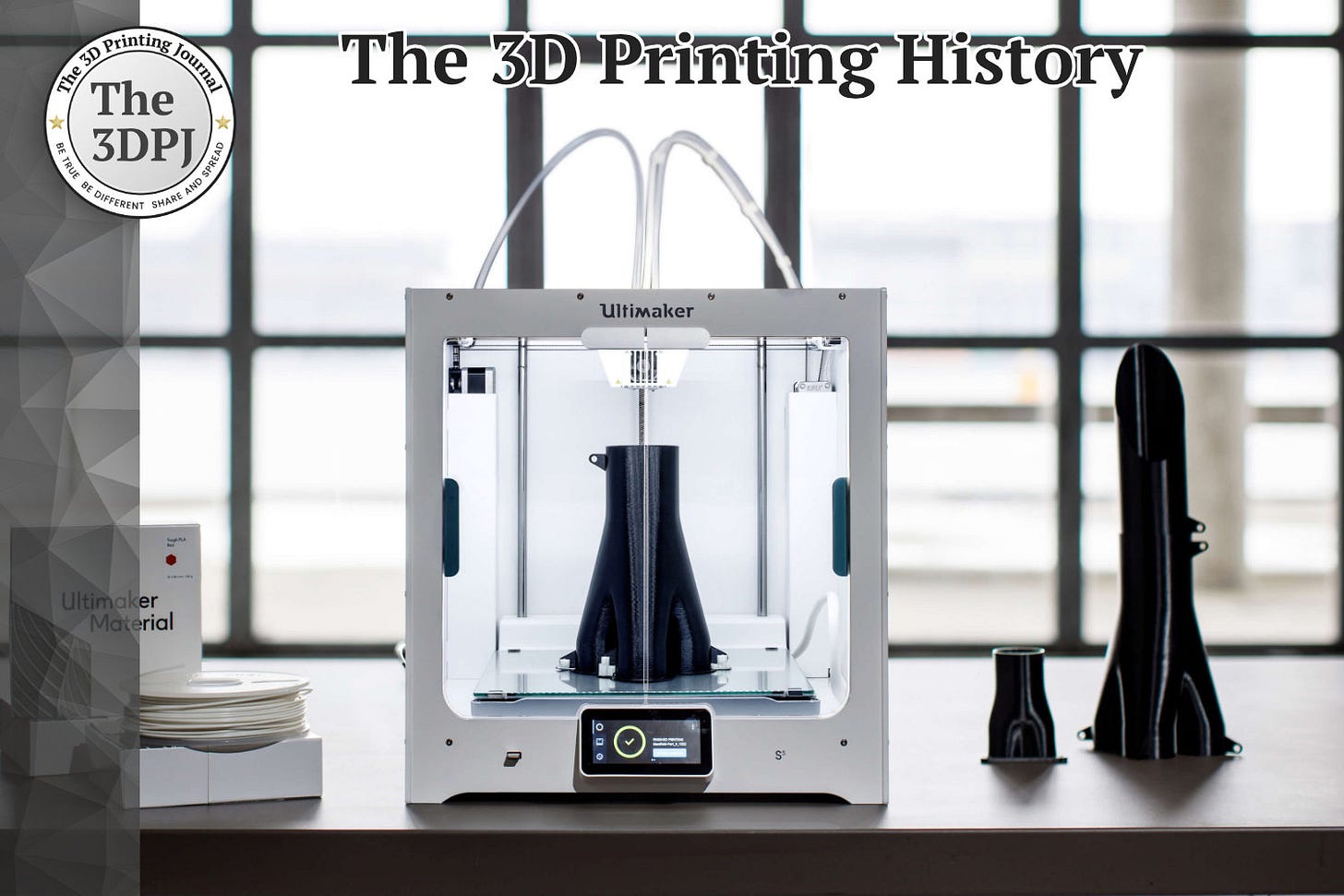

Airbus chose Ultimaker S5 printers, CURA software, and 3D printing materials

On February 13, 2019, Airbus, one of the world’s largest aerospace manufacturers, decided to implement Ultimaker 3D printers in its European facilities. The company chose Ultimaker S5 printers, CURA software, and 3D printing materials to locally produce tools, jigs, fixtures, and lightweight design components. On one hand, Airbus appreciated the quality of Ultimaker's 3D printers, which were highly regarded at the time, and on the other, it valued the matter of security of data and whole manufacturing process.

In 2019, Ultimaker was at the top of its game. The company had already secured several lucrative contracts as the exclusive supplier of its 3D printers to various production facilities, including Philips. The contract with Airbus was another significant milestone—albeit a highly prestigious one. The 3D printers were not intended for manufacturing end-use parts for aircraft but rather for producing tools and fixtures. However, even in this capacity, efficiency, reliability, and data security were crucial factors.

Strict safety and certification regulations in the aerospace industry can complicate production processes, but Ultimaker provided certified solutions and high-quality composite materials with enhanced durability. Additionally, Ultimaker committed to offering global technical support and maintenance services, which was a key factor for Airbus.

GET FREE HISTORY BOOK: ‘2012 in AM’

Airbus used Ultimaker S5 printers, which at the time were the most advanced devices in the company’s portfolio. Ultimaker also supplied CURA software, materials, spare parts, and technical support services. This comprehensive approach allowed Airbus to fully leverage the potential of 3D printing within its facilities.

Airbus’s decision to collaborate with Ultimaker aligned with the company’s broader strategy of investing in additive manufacturing technologies. Airbus had already been using 3D printing to produce aircraft components, such as parts for the A350 XWB, in partnership with Liebherr-Aerospace, which supplied 3D-printed landing gear components.

With Ultimaker, the focus was only on manufacturing tools and fixtures, but it demonstrated that 3D printing is not only applicable to aircraft part production but also plays a crucial role in optimizing manufacturing processes.

Source: www.voxelmatters.com