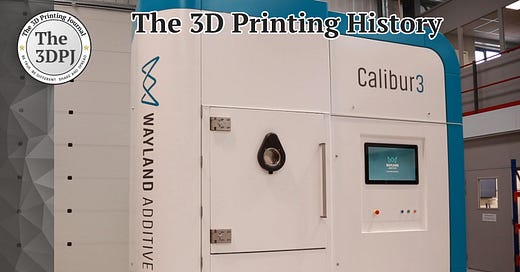

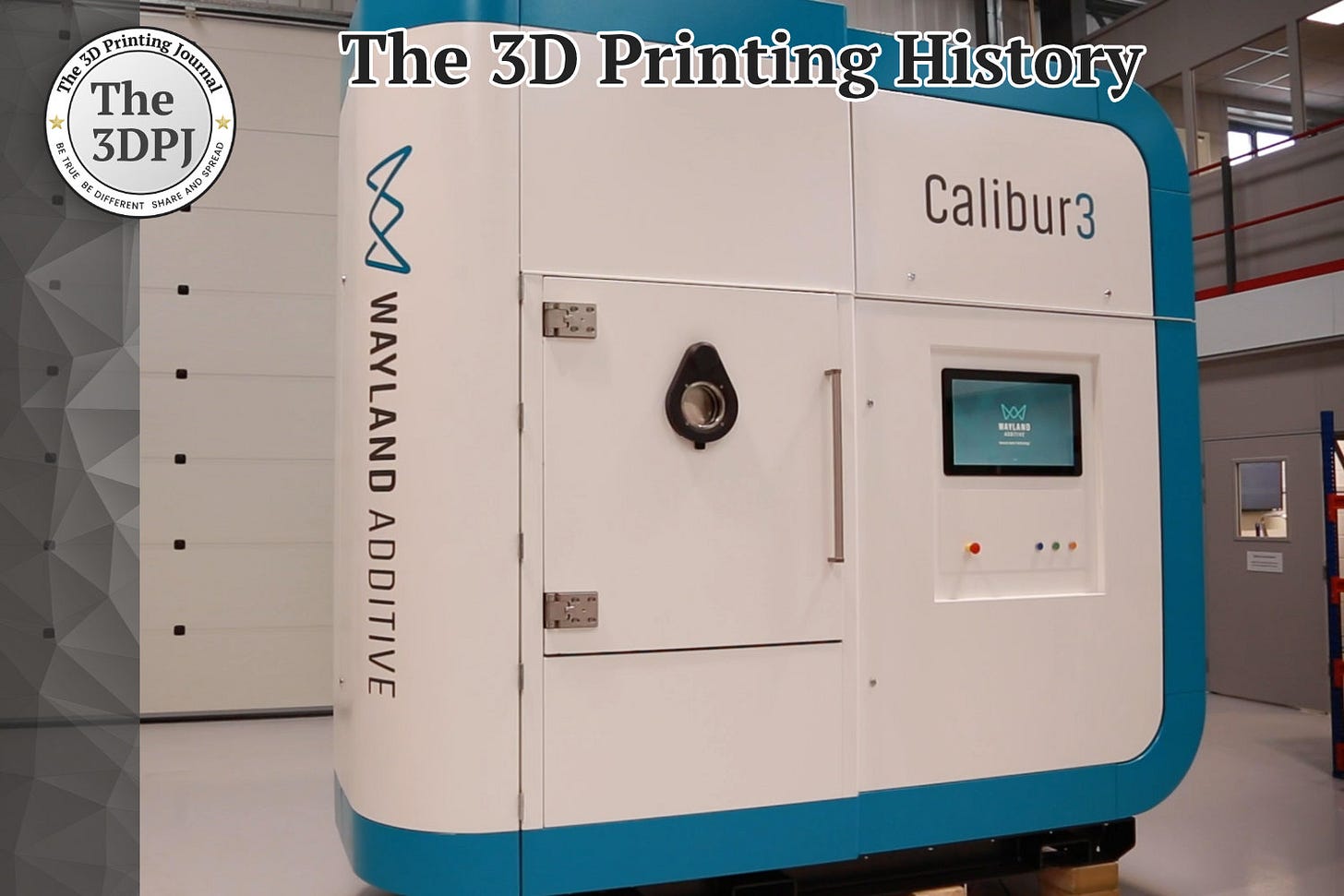

03-16-2021: Wayland Additive introduced the Calibur3 electron beam metal 3D printer

The machine was based on proprietary NeuBeam technology

On March 16, 2021, Wayland Additive unveiled its long-awaited debut metal 3D printer, based on its proprietary NeuBeam technology, a variation of the Electron Beam Powder Bed Fusion (E-PBF) process, which involves fusing metal powder using an electron beam. This process focuses energy solely on the printed part, rather than the entire powder bed.

The initial launch of the system was planned for January 2021, but due to restrictions related to the COVID-19 pandemic, the event was postponed. The official media presentation eventually took place in March, with a physical showcase event held in mid-May 2021 at the company's headquarters.

The Calibur3 was Wayland Additive's first commercial 3D printer. Unlike traditional E-PBF systems, the NeuBeam method neutralizes the accumulation of electrical charges in the powder, eliminating the need for expensive gases such as helium and pre-sintering of the powder bed.

This process concentrates energy exclusively on the printed part, rather than the entire powder bed, preventing the formation of so-called "sintered cake" – a problem typical of other E-PBF machines that complicates post-processing. The fast electron beam deflection system allows for precise control of the process, eliminating the need for mirrors or mechanical deflection systems, which reduces variables such as optical system inertia. As a result, the Calibur3 enables the printing of larger parts with lower residual stresses, setting it apart from competitors, including laser PBF systems.

The Calibur3 featured a build area of 300 x 300 x 450 mm. Wayland Additive also emphasized that the machine offers better energy efficiency compared to similar electron beam devices. The system was equipped with advanced real-time monitoring features, including light scanning, electron imaging, and infrared cameras, enabling quality control at every stage of the printing process.

The NeuBeam technology also allowed for working with a wide range of metal materials, including alloys that are difficult to process in traditional methods, such as refractory metals and highly reflective alloys. The process operated at temperatures above the metal's annealing point but below the powder sintering temperature, eliminating the need to anchor parts to the build plate and subsequent wire cutting or annealing, significantly reducing post-processing time and costs.

Wayland Additive is a British company based in Huddersfield. Its origins trace back to a collaboration with Reliance Precision, the parent company from which Wayland licensed the NeuBeam process. The company was officially established as an independent entity in 2019. Following its debut, the company intensified its commercial efforts, signing distribution agreements, including one with HTL Co. Japan in 2021, and expanding its production facilities in 2022.

Source: www.waylandadditive.com