03-28-2016: Solidoodle announced the suspension of operations

It marked the end of its less then five-year-long career

On March 28, 2016, Samuel Cervantes, the founder and CEO of Solidoodle, announced on the company’s blog that it was suspending operations, which ultimately led to its complete shutdown. The collapse of one of the most important American manufacturers of desktop 3D printers was the result of a series of problems that began with the failed introduction of its sixth-generation device—the Solidoodle Press.

The 3D printer, priced at around $600, was supposed to be Solidoodle’s greatest technological achievement—easy to use, equipped with a heated bed, and featuring auto-leveling. Unfortunately, its build quality and reliability left much to be desired. The issues included cheap components, unreliable stepper motors, fragile build plate glass, and problematic software. The product failed to meet the expectations of both beginners and experienced users alike.

Earlier, Solidoodle had moved production from its home base in Brooklyn to China in an effort to reduce costs and scale up production. However, the manufacturing partner failed to meet quality standards, despite Cervantes' efforts in training and supervision. The 3D printers produced in China were defective, leading to a wave of returns and customer dissatisfaction.

The situation worsened due to the West Coast port strike in the U.S. in 2014, which delayed the delivery of hundreds of 3D printers ordered for the holiday season. The devices arrived only in March 2015, limiting the time available for testing and quality control while also depriving the company of a crucial cash flow boost.

Declining sales following the Press debacle led to layoffs and a further deterioration in customer service. In July 2015, the company secured funding to try to save itself, but it was not enough to reverse the downward trend. By the end of 2015, Solidoodle had run out of funds, stopped accepting orders, and laid off its remaining employees. Cervantes exhausted nearly all of his savings in an attempt to save the company, but ultimately, it was in vain.

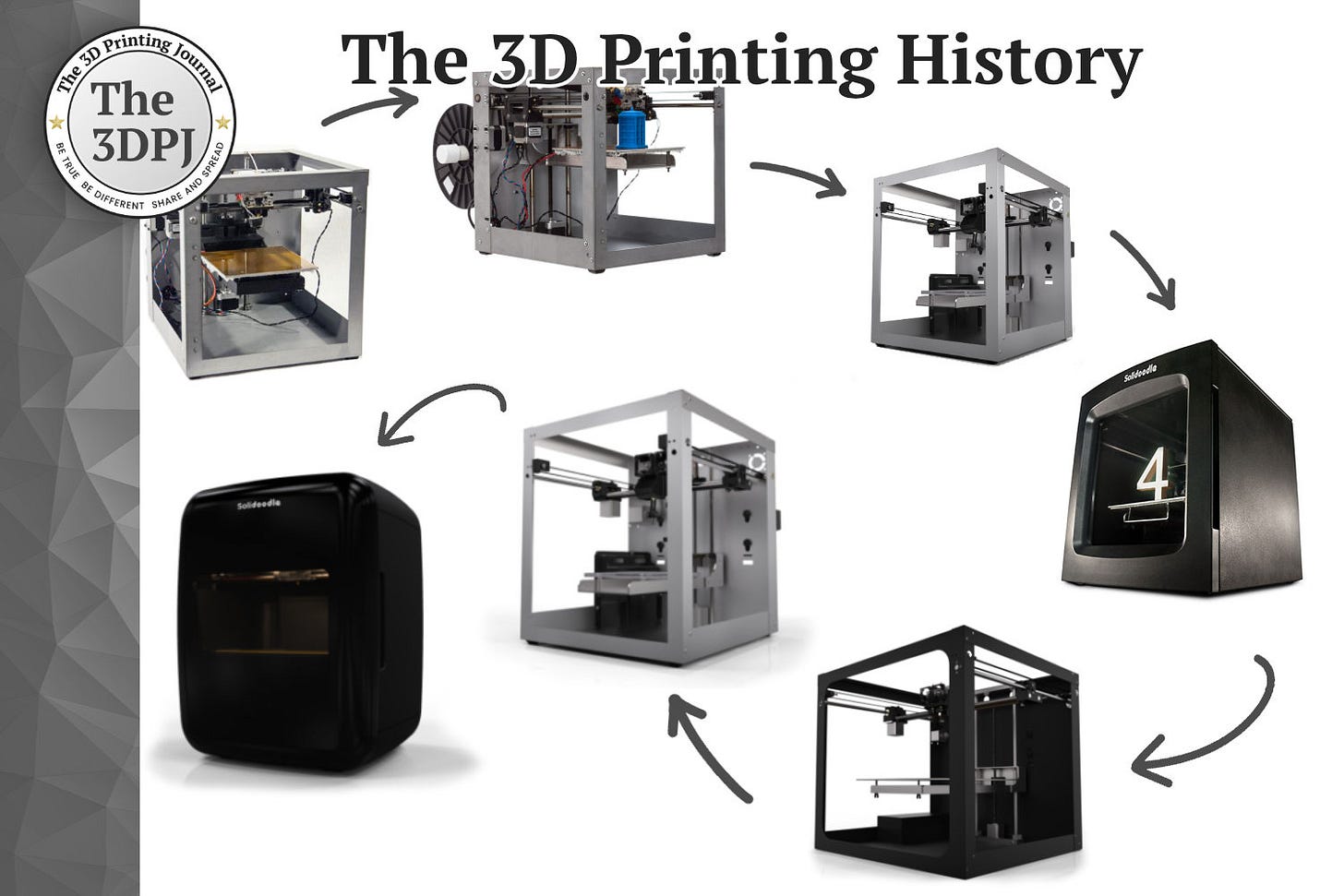

Solidoodle was founded in 2011 by Sam Cervantes in New York, with headquarters in Brooklyn. From the beginning, it stood out by offering ready-to-use, factory-assembled 3D printers at significantly lower prices than the competition—the first model cost around $500.

Between 2011 and 2014, the company released seven printer models (Solidoodle 1, 2, 3, 4, Workbench, Workbench Apprentice, and Press), and most of them were produced in its Brooklyn facility. Solidoodle quickly gained popularity thanks to its low prices and ease of use. At its peak, it employed 70 people and delivered over 10,000 printers to 60 countries, making it one of the leading players in the consumer 3D printing market.

Source: www.solidoodle.com