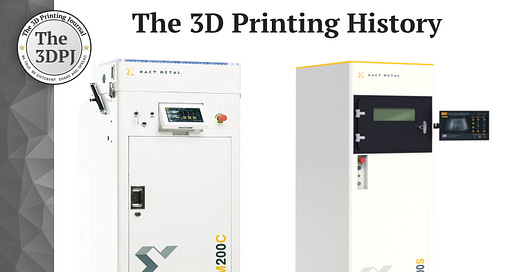

04-03-2018: Xact Metal introduced two metal 3D printers – XM200C and XM200S

The compact printers featured an open architecture

On April 3, 2018, Xact Metal unveiled two new 3D printers, the XM200C and XM200S, featuring the Xact Core system. This technology replaced traditional galvanometric mirrors and F-theta lenses with lightweight, fast-moving mirrors that precisely positioned the laser over the build area.

This innovative approach reduced production costs and improved print efficiency. The laser maintained a constant angle of incidence, while the simplified gas flow over the powder layer enhanced part quality.

The compact printers featured an open architecture and a build volume of 127 × 127 × 127 mm. The XM200C, priced at $80,000, included a 100W laser and supported materials such as tool steel, bronze, stainless steel, and specialty alloys. The XM200S, at $130,000, was equipped with a 200W laser and an advanced optical system with a galvanometer, allowing it to print with aluminum and titanium. Both machines featured remote monitoring, a user-friendly touchscreen interface, and the flexibility to work with custom print parameters.

Xact Metal was co-founded by Matt Woods, a Penn State engineering graduate, who developed an affordable metal printing technology. The company operated out of Innovation Park at Penn State and gained recognition for its innovative approach to metal 3D printing. Woods has not been associated with the company since 2021.

In September 2022, Xact Metal announced the XM300G series, designed for larger part production and serial manufacturing. Currently, the company has 26 distribution partners across 48 countries, providing global customer support.

Source: www.3dprint.com