08-03-2017: Mercedes-Benz Trucks announced the production of spare parts based on AM

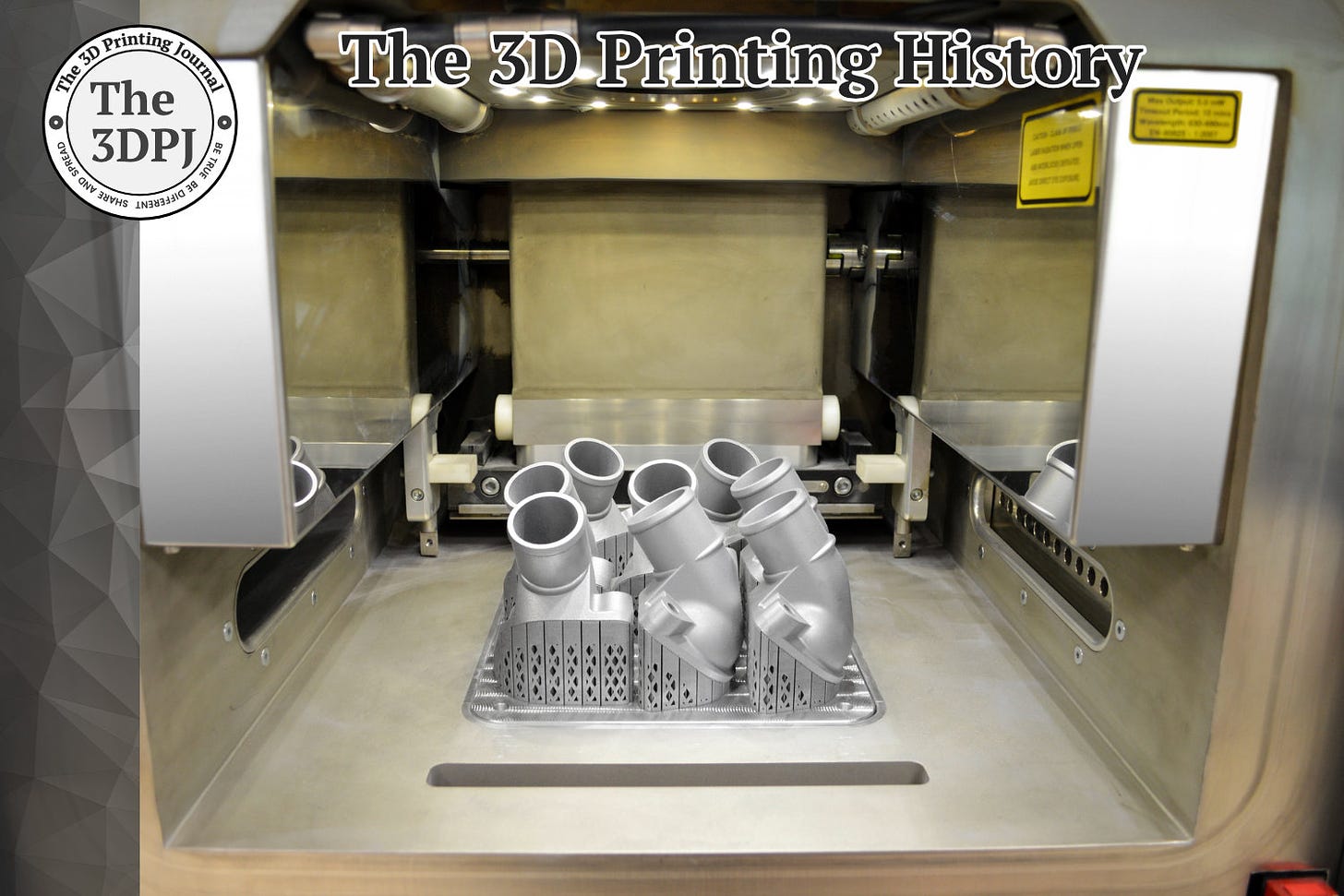

Mercedes presented an aluminum thermostat cover for older trucks made on Renishaw metal 3D printers

On August 3, 2017, Mercedes-Benz Trucks introduced the first spare parts for their trucks made using industrial 3D printers based on metal alloys. The first replacement part produced was a thermostat cover designed for trucks (including older models of the Unimog brand). The part successfully passed durability tests, thus meeting the stringent criteria that demonstrate the brand's reliability.

According to specialists from Mercedes-Benz Trucks, 3D-printed components exhibited the same functionality and durability as parts made using conventional methods. The manufacturing process allowed for significant material savings compared to subtractive methods. The unused aluminum powder in the 3D printing process was cleaned and then reused through recycling.

The first metal AM replacement part followed the production of a number of plastic components, which Mercedes had been 3D printing since mid-2016. Developed by the company’s Customer Services & Parts division in collaboration with researchers and pre-developers at Daimler AG, the 3D printing process for replacement parts has been firmly established as an alternative method for the production of components in small batches.

The introduction of additive manufacturing technology in the production of spare parts was further proof of the company's leading position among global automotive manufacturers.