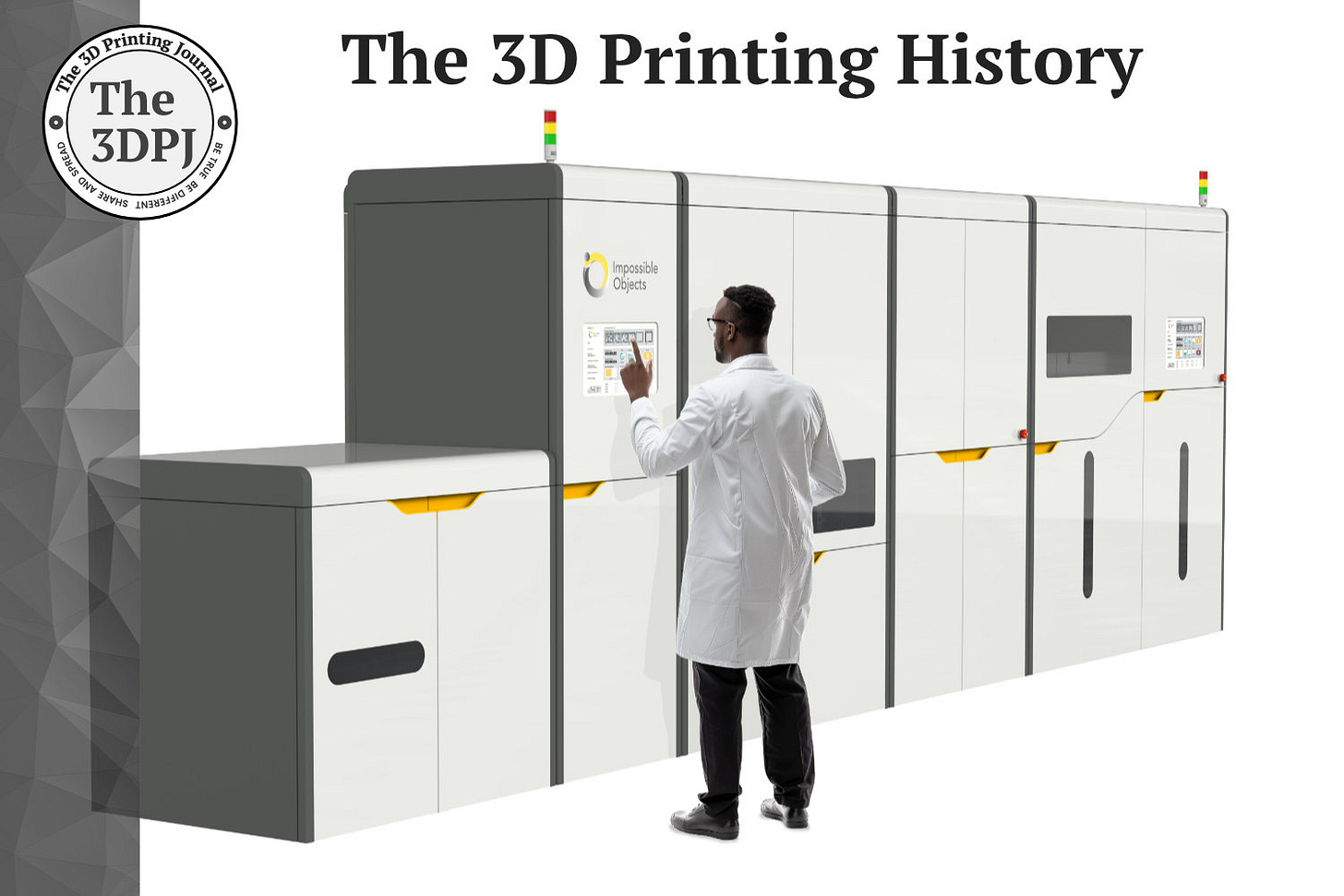

12-12-2014: Impossible Objects received a $2.8 million investment to create “the world’s fastest 3D printer

The machine was producing parts from composites of polyamide and carbon fiber, fiberglass or Kevlar

On December 12, 2014, Impossible Objects announced the funding, provided by OCA Ventures and a group of private investors. The funds were aimed at developing an innovative method for manufacturing composite objects using polyamide along with carbon fiber, fiberglass, or Kevlar.

Impossible Objects was founded by Robert Swartz, an entrepreneur who recognized the potential of advanced materials in additive processes. The mission of Impossible Objects was to overcome the limitations of traditional 3D printing technologies, which were often too slow and limited in the range of materials they could use.

The company developed a groundbreaking process that involved applying layers of polymer onto thin fiber sheets and then bonding them under heat and pressure. Excess material was mechanically removed, resulting in lightweight yet extremely durable components. By using composites such as carbon fiber and Kevlar, the manufactured parts exhibited outstanding mechanical properties, outperforming standard thermoplastics and metals.

At that time, Impossible Objects focused its offerings primarily on the aerospace, automotive, and medical sectors, where high reliability of components was essential. A key goal was also to increase production speed to levels comparable to injection molding. The company’s method allowed for high precision, excellent surface quality, and minimal deformation, making it an attractive alternative to conventional machining processes.

The $2.8 million capital infusion enabled the company to expand its activities in sales, marketing, and the production of new machines. At the time of securing the investment, Impossible Objects employed only five people, which made its achievements even more remarkable. The financial boost facilitated further research and development, resulting in machines capable of industrial-scale production of components, not just prototypes.

Recently, at the Formnext trade fair, the company announced the introduction of its 3D printers to the European market.

Source: www.impossible-objects.com