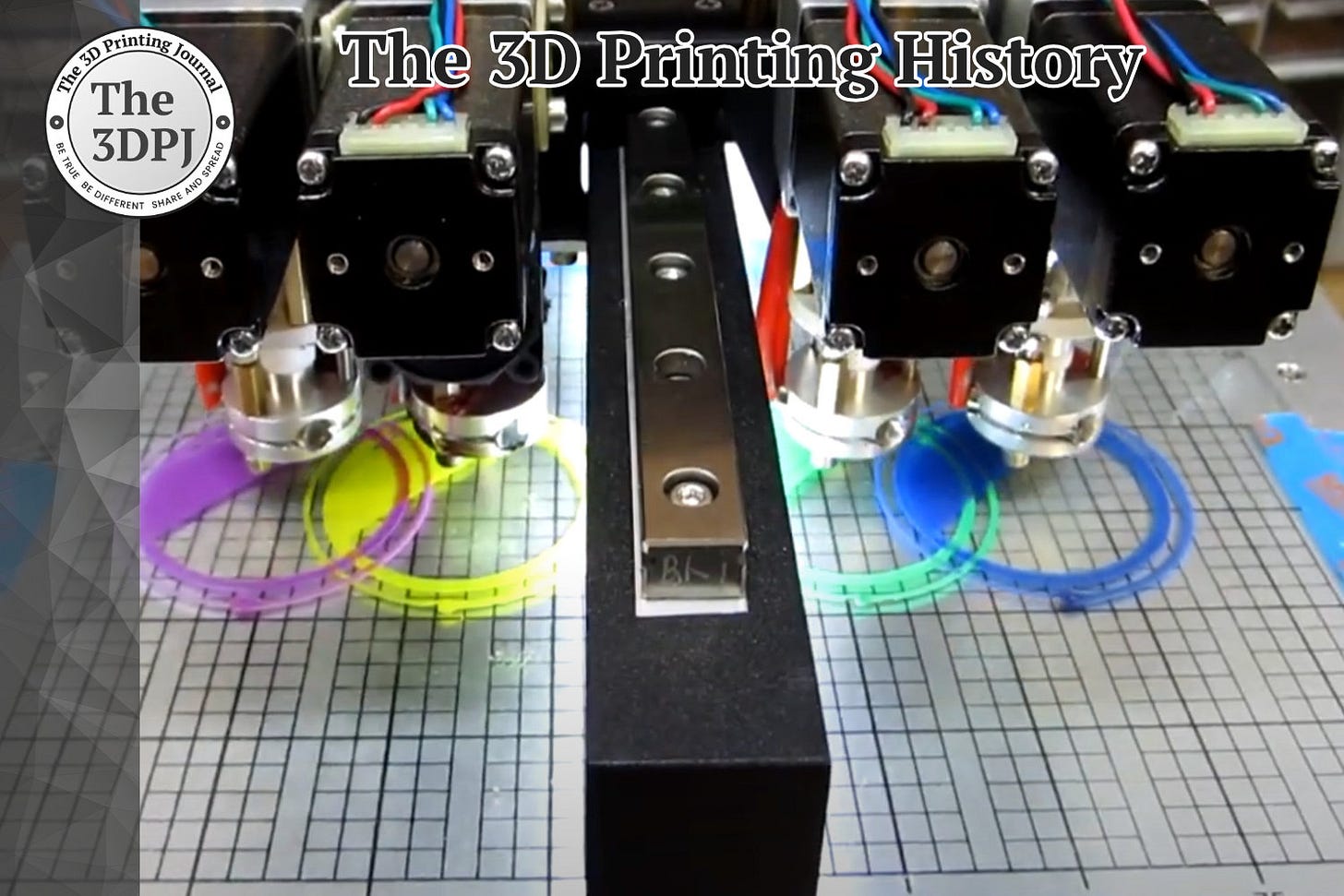

12-24-2013: Hyrel3D demonstrated 3D printing in FFF technology using four extruders simultaneously

Hyrel3D System 30 was equipped with four printing extruders

On December 24, 2013, Hyrel3D (Hyrel International, Inc.), an American manufacturer of FFF 3D printers, published a video showcasing the capabilities of its latest device—the System 30, equipped with four printing extruders. This was groundbreaking at the time, as other desktop-grade 3D printers of this type were still in the early stages of development for dual-head printing.

Moreover, the System 30 allowed for the combination of multiple materials—not only thermoplastics but also unconventional ones like clay, porcelain, silicone, Sugru, Play-Doh, wax, chocolate, cheese, and peanut butter (yes, that’s what the manufacturer claimed 🤔).

In hindsight, such experimental constructions did not stand the test of time—after all, combining ABS with clay or silicone has little practical application. However, Hyrel3D pushed the boundaries of 3D printing to the extreme.

Hyrel3D was founded in 2012 by Karlson Gifford, an engineer and inventor who developed highly versatile and modular 3D printers. Leveraging his technical expertise, Gifford designed devices capable of printing a wide range of materials, from traditional filaments to more unconventional mediums such as pastes and gels. Hyrel3D was conceived as a project aimed not only at hobbyists but also at scientific and industrial applications.

The company initially sought funding through a Kickstarter campaign launched on September 6, 2012, which raised over 150% of its $50,000 funding goal.

Unveiled in the fall of 2013, the System 30 significantly stood out among other desktop 3D printers of its time. It featured a fully enclosed build chamber and a dedicated, sealed filament container. The 3D printer also had a fume extraction system installed. Additionally, the System 30 came equipped with its own onboard computer featuring a 14-inch touchscreen.

The printer was operated via a PC powered by an Intel Atom processor, allowing it to function independently without the need for connection to an external computer. While this may seem trivial today, it was a small revolution for 3D printers at the time, making it a completely standalone device.

Regarding 3D printing with four extruders, Hyrel3D claimed it primarily saved time—the 3D printer could produce four identical objects simultaneously, significantly speeding up production. Alternatively, each extruder could be loaded with a different filament (in terms of color or type) to print a single, more complex object.

Hyrel3D continues to develop its printers to this day, enabling work with materials such as ceramics, emulsions, biological substances, high-temperature filaments (up to 450°C), CO2 and diode lasers, spindle tools, electrospinning, pick-and-place systems, and in-situ metrology. Most of these devices are now used in university and government laboratories across the United States.

Source: www.youtube.com