40 years revisited—look how much we’ve achieved!

What have we managed to achieve in four decades of Additive Manufacturing?

Today marks exactly 40 years since Charles Hull filed a patent application for Stereolithography — the world’s first additive technology.

August 8, 1984, has since been considered the symbolic date of the creation of 3D printing.

However, it’s not as obvious as it may seem…

Hull was not the first to develop this method. There were others.

Hull was not the first to file a patent, and his patent was not the first to be granted. There were others.

I have written a separate article on the origins of Stereolithography and all the nuances (and career tragedies) associated with it, which you can read on the 3DPrint.com portal.

But despite all this, there is a very significant reason why we should recognize Hull as the true creator of 3D printing.

It was Hull who built a working machine around this technology, found customers for it, established a company around it — and ultimately created a market.

Therefore, he is not just the inventor of “stereolithography — the world’s first additive technology,” but the creator of the entire business and market that grew around it.

So, additive manufacturing is 40 years old. Is that a lot or a little? Can we call a 40-year-old technology old?

What does 40 years of existence really mean?

In the case of a human life — that’s quite a lot… Many people at this age have already passed the halfway point (though they may not realize it). Many haven’t even reached this age…

So, looking through the lens of a human life, 40 years is a pretty long time… Sometimes it is the whole life!

But what about in the case of manufacturing technologies? Let’s take a look at some alternatives…

Casting — well, casting is a 7,000-year-old process; the oldest surviving casting is a copper frog from 3200 BC.

Welding — the earliest examples of this process come from the Bronze and Iron Ages in Europe and the Middle East.

Injection Molding — the first patent was filed in 1846; the technology began to be widely used in the 1940s for wartime industry during World War II.

CNC Milling — the first CNC machines were built in the 1940s and 1950s.

Thermoforming — like CNC milling, it became widespread in the 1940s and 1950s.

As you can see, 40-year-old 3D printing is still a child compared to the technologies mentioned above…

However, to be completely fair, we must consider one more factor.

All the major 3D printing techniques were developed in the 1980s and 1990s (SLA, FDM, Binder Jetting, SLS, SLM, DLP etc.). For the first two decades of their existence, they were protected by patents.

As a result, very few people knew about or used them.

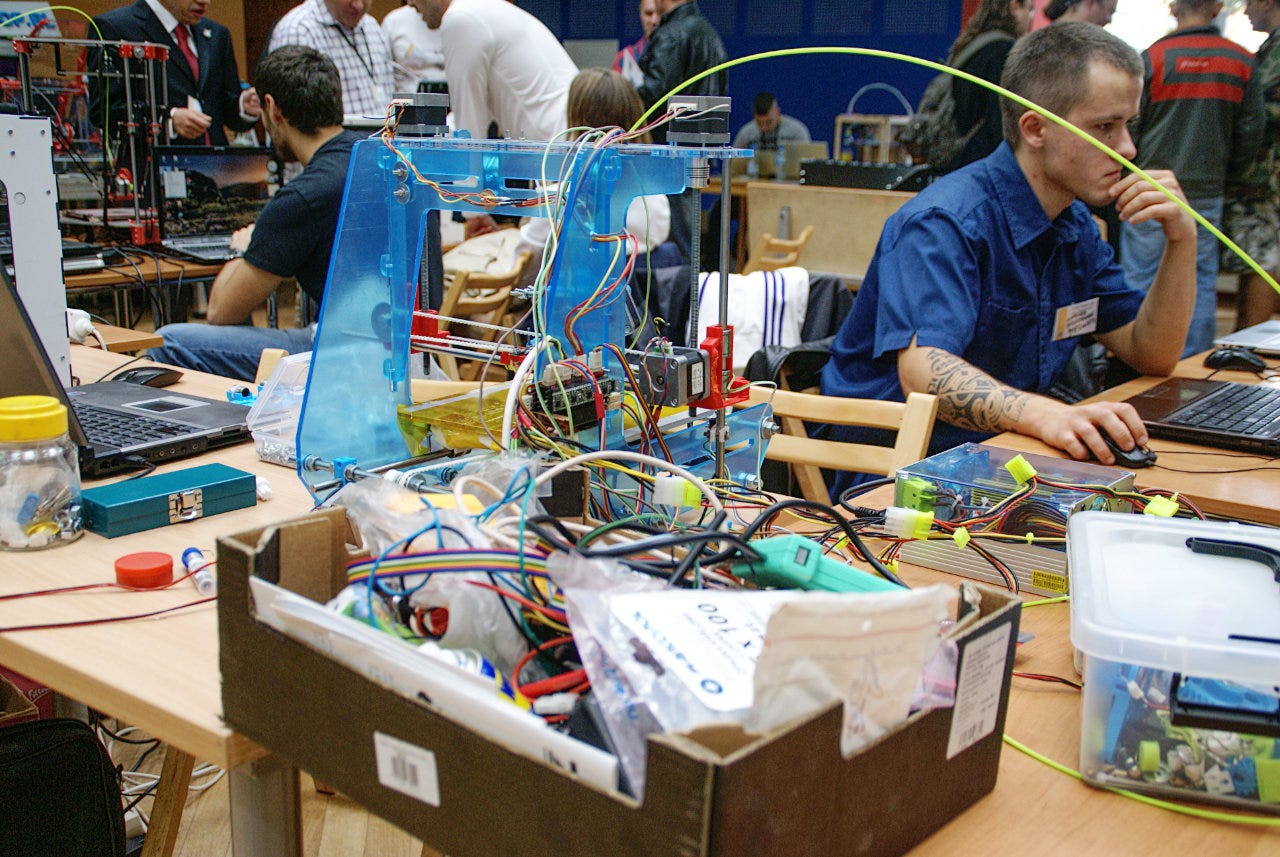

This changed in the late 2000s thanks to Adrian Bowyer and the RepRap project. Bowyer, along with a group of hobbyists and technology enthusiasts, popularized 3D printing worldwide, making it (for a time) one of the most sought-after new technologies.

So, in the minds of a broad audience, 3D printing has really only been around for 10–15 years!

That’s about as long as Android has existed!

In the context of industrial manufacturing methods, that’s almost nothing.

Where did we stand 10 years ago?

Most companies shaping the AM market are either about to turn 10 years old or have just crossed that milestone. Generally, a 10-year-old company in this industry is considered a seasoned veteran, while a 20-year-old company is really old.

My journey with 3D printing began in January 2013. The 3D printing industry looked completely different then than it does today. For example, in my home country of Poland, it practically didn’t exist…

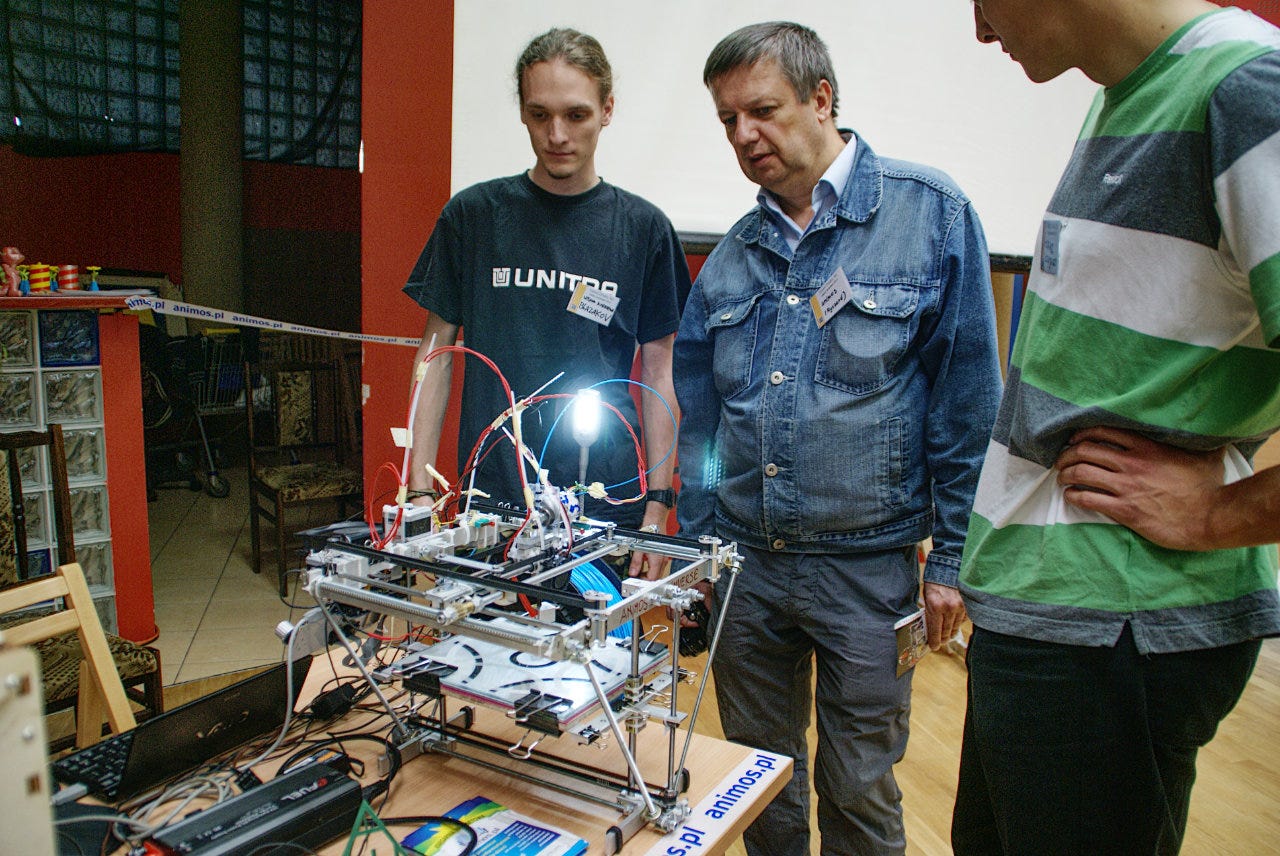

In 2013, industrial machines were the domain of large companies or research institutions. Small and medium-sized businesses either couldn’t afford professional-grade 3D printers, or if they could, they didn’t consider it wise to spend money on such a purchase!

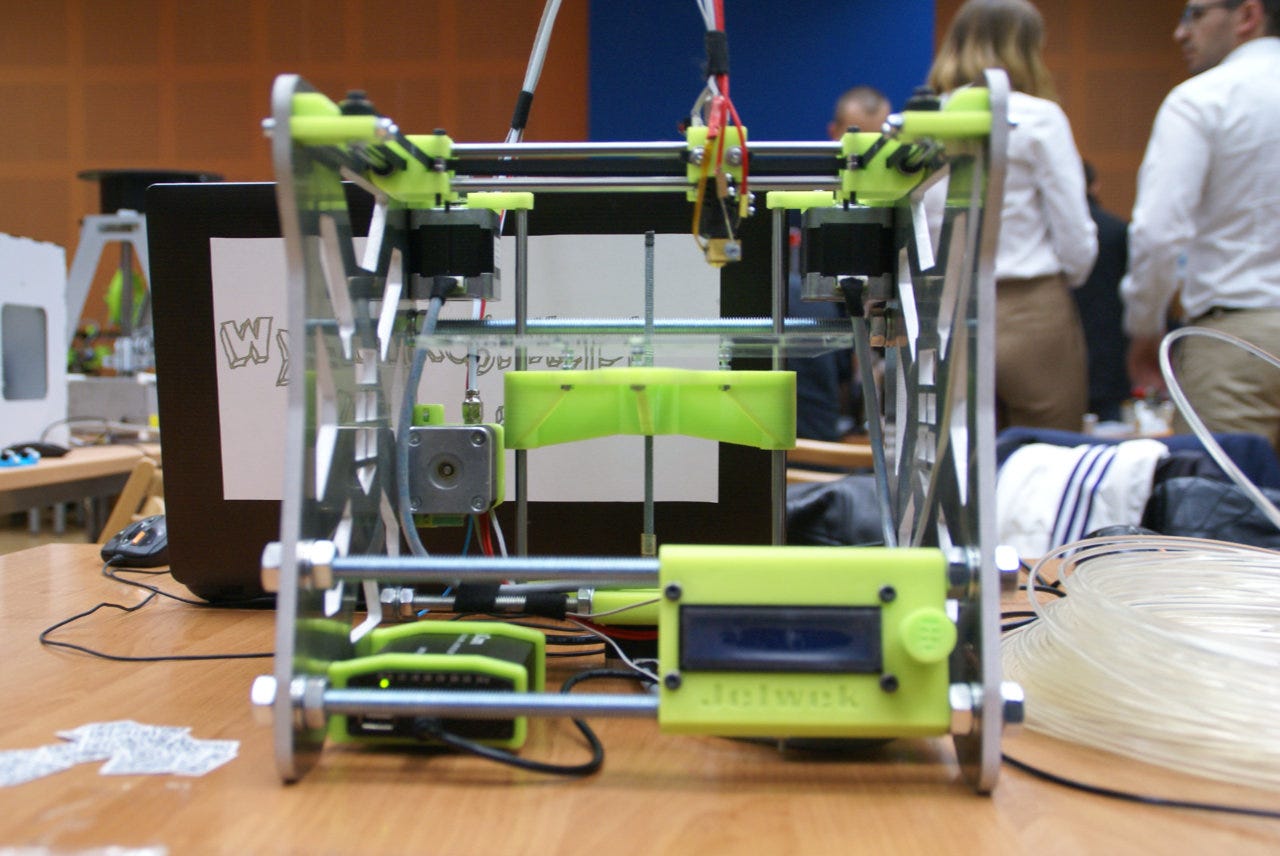

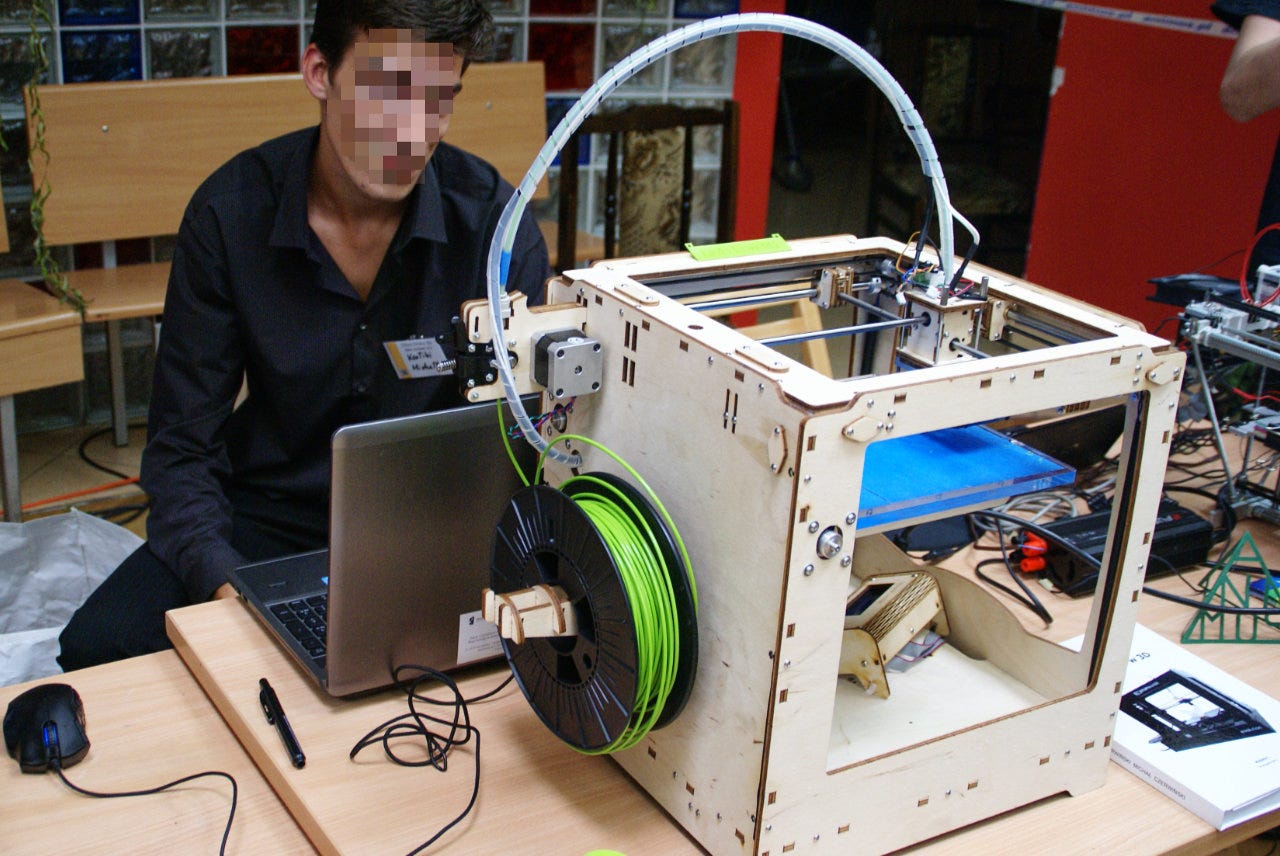

Desktop 3D printers were — well — amateurish and very unprofessional. Moreover, their price didn’t match their quality. The 2010 MakerBot Cupcake CNC cost $750 but had a tiny build area of 10 x 10 x 13 cm, a wooden plywood case, and a tangle of cables around it. The Ultimaker Original (also with a wooden case) cost around $1,000.

What’s more, most desktop 3D printers were sold as DIY kits. So, not only did you have to learn how to operate them — you had to be able to assemble them first!

We had to wait until the mid-2010s for desktop photopolymer 3D printers. The first ones were B9 Creations and Formlabs, but it wasn’t until the end of that decade, thanks to Photocentric and then the Chinese company Anycubic, that resin-based 3D printing really gained traction in the market.

Let’s rewind… Desktop 3D printing based on resins has really only been on the market for 6–7 years!

In 2013, 3D printing was used for prototyping. In fact, 3D printing was more often referred to as “Rapid Prototyping” than “Additive Manufacturing.” The latter term became popular later…

READ MORE: Why is 3D printing no longer called 3D printing?

At that time, the idea of using 3D printers to produce end-use parts was a goal we were striving toward. You know, sort of a “dream.”

Mass production was something that was viewed the way we see a mission to Mars today. As something that is inevitable, will happen someday, but not too soon… Maybe not in our lifetime.

As for large companies, the news of the day was that company X was “considering” entering 3D printing. We had to wait several more years for their actual presence (and some of them have already withdrawn from 3D printing).

So, in 2013, we were in a completely different place than we are today.

And how much has been achieved in these 10 years?

Where are we now?

Yes, a lot of crap has happened during that time.

Many companies have gone under. Some of them deservedly so — they were outright frauds (or had a „very loose approach to honesty”).

Many interesting projects were abandoned. Some of them are truly missed…

SEE: 10 most stunning 3D printers in the history of consumer 3D printing

But in hindsight, I have to say it was a path we had to take. Through lies, irregularities, manipulations, and sometimes even outright crimes (shout out to Kickstarter!). There simply was no other way.

READ MORE: You’ve been sold short to a scam

Today, the AM industry is once again in a slump, slowly clawing its way out. But as history has proven, it will succeed once again.

3D printing technology is in a completely different place now:

Rapid prototyping — it’s standard.

Manufacturing of single end-use parts — it’s standard.

Low scale manufacturing — it’s standard.

On-demand production of spare parts — it’s standard.

Production of dental applications — it’s standard.

Production of jewelry applications — it’s standard.

You name one of hundreds of other more or less niche applictions — yes, it’s a standard too…

Mass production — rapid manufacturing — is still far from being fully realized (although some are already doing such things), but it’s no longer the distant future it once seemed.

We’ll likely start producing parts serially on 3D printers before a human sets foot on the surface of Mars.

Ten years ago, we were excited that GE or HP were considering entering 3D printing. Today, they are leading players in this market.

Sure, many others have dropped out (BASF, Braskem, Canon, Mitsubishi Chemical…), but new ones have stepped in (Nikon, Mimaki, DMG Mori…).

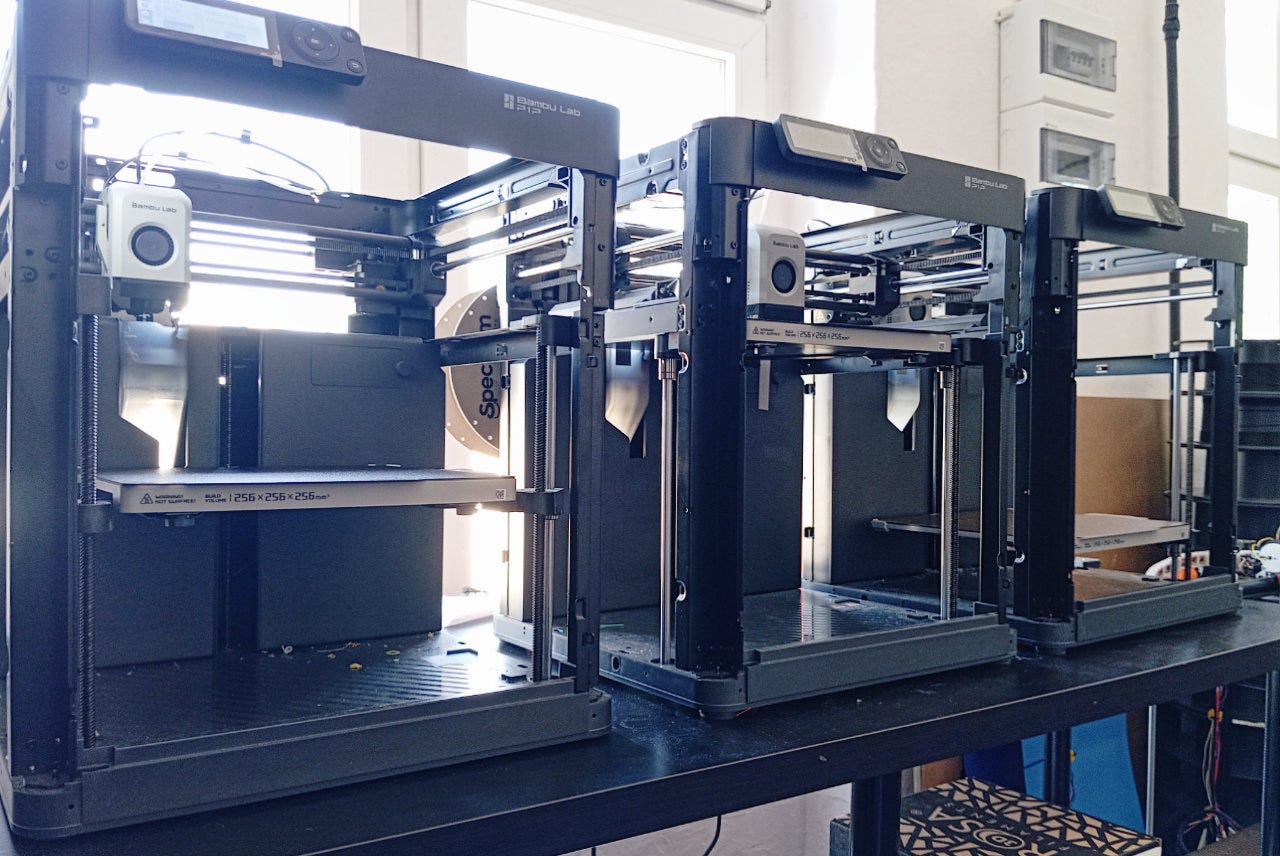

Desktop 3D printers are no longer wooden cases, protruding screws, and tangled cables — they are machines like Bambu Lab, capable of producing parts with speeds and accuracy unheard of 2–3 years ago.

In these 10 years, we’ve achieved a great deal. It wasn’t a walk, it wasn’t even a run — it was a sprint!

There’s still a lot to be done, but we’re on the right path.

Right now it’s a bit rough, bu sometimes it’s worth stepping aside and taking a look at it all from a distance.