Atomic Layer of the Day:

Theoretically, we are getting closer to the repeatedly delayed and postponed launch of Bambu Lab’s new 3D printer. According to the latest unofficial reports, the successor to the X1 & P1 series was expected to be released in the first quarter of 2025.

The first quarter ends in two weeks, and based on the trade show calendar, if a reveal were to happen, it would most likely take place at TCT Asia in Shanghai, which starts this Monday.

The issue, however, is that Bambu Lab is not listed among the exhibitors—a list that includes virtually everyone, including Western manufacturers such as 3D Systems, Lithoz, and voxeljet. This looks odd and raises some questions.

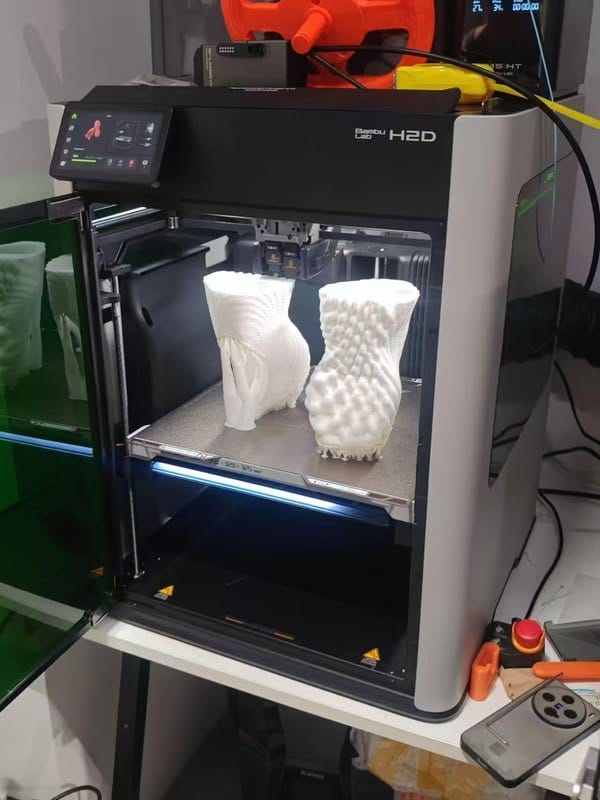

Meanwhile, yesterday, another leak surfaced, allegedly showing Bambu Lab’s new 3D printer. The author of the leak is 梁凌晖. Here’s how new 3D printer looks like:

The photo appeared on the Bambu Lab Official User Group on Facebook, confirming most of the details that were first leaked in early December 2024, when an image of the box design surfaced.

What we know so far:

The new printer will be called H2D (old news).

It will have dual extruders (old news).

Build volume: 350 x 320 x 325 mm (confirming previous rumors that it would be around 30 cm in XYZ axes).

It will feature a heated AMS HT system (new, but secondary news).

A module labeled “LASER 10W” is visible on top, with a safety switch on the side and green protective panels on the doors and sides—suggesting a laser engraver feature (this is completely new!)

The price speculation in Facebook comments suggests around €3000, but at this point, it’s purely guesswork. It’s also unclear what this price actually includes—the 3D printer itself? The printer with AMS? The printer with additional accessories (if such options exist)? No one knows for sure.

What’s certain, however, is the lack of enthusiasm from the Facebook group members who saw the leak.

Seriously. You’d expect Bambu Lab’s Official User Group to be full of brand fanboys and hardcore enthusiasts, yet the comments are mostly reserved, with some even showing pure disappointment:

"If this is correct, this is entirely disappointing. There’s absolutely nothing new or revolutionary here. Dual extruder is done time and time again (…) What we really needed was a tool changer like the Prusa XL. The laser is also a really weird design choice. The laser will generate ash and oil residue that is going to get on everything, especially sensitive surfaces like the LiDAR lens, as well as the print surfaces, which will make filament adhesion not work. (…) Hoping this is a fake image, but it sure does look authentic, which is again quite disappointing as there is absolutely nothing new here.”

By Brian Martin

Overall, users are complaining about the build volume—which they feel is still too small (they were expecting 350 x 350 x 350 mm)—and the lack of any groundbreaking innovation. If the laser head feature turns out to be real (I have mixed feelings about this myself...), it’s probably not what people were actually waiting for.

For now, I’m not going to jump to conclusions, because aside from one leaked image of the printer and a label on the box, we don’t know anything else. It’s possible that what we’re seeing is 100% of what Bambu Lab has to offer, but it’s also possible that this leak is just one of several upcoming new products.

One thing is certain—Bambu Lab has set the bar so high that if they fail to surprise users in a positive way, they might end up like Ultimaker within the next 2-3 years.

And I’ve been warning about this for a long time ago…

Atomic Layer from the Past:

03-15-2021: Desktop Metal launched Desktop Health.

Join AM World Map and fill your country or region with Additive Manufacturing!

News & Gossip:

Researchers at the Beckman Institute have developed "Growth Printing" (GP), a new additive manufacturing method inspired by tree growth. Led by Professor Sameh Tawfick, the process uses a self-propagating polymerization front to create polymer parts efficiently without molds or complex equipment, offering energy-efficient production and precise shape control.

Aibuild has joined the 3MF Consortium to advance multi-axis additive manufacturing. The company is contributing to the 3MF Toolpath extension, which aims to create a universal, machine-agnostic control format for complex deposition processes.

BLT has partnered with GoEngineer to distribute its metal additive manufacturing solutions in North America. This collaboration aims to expand BLT’s presence in key industries like aerospace and automotive, providing local support and accelerating the adoption of advanced manufacturing technologies across the region.

As an owner of several different Stratasys FDM printers over the years (Dimension, now F370-CR), I used to boast that we could bring in a part file, hit the print button, and await our part. Meanwhile, the landscape started to fill with "Brand X" FDM printers that required way more patience to set-up, tweak settings, diagnose failures, etc. Companies like Bambu are leveling the playing-field, and we've lost a lot of service business as these printers become easier to run and reliably print parts at a much lower cost-of-ownership. The next few years are going to be, uh, interesting.