Rosotics and Siemens join forces to create „Next Generation Super-Heavyweight Platform” in Naval Manufacturing.

It will be supported by Siemens' industry-leading architecture – Sinumerik One, known for its unparalleled precision and efficiency.

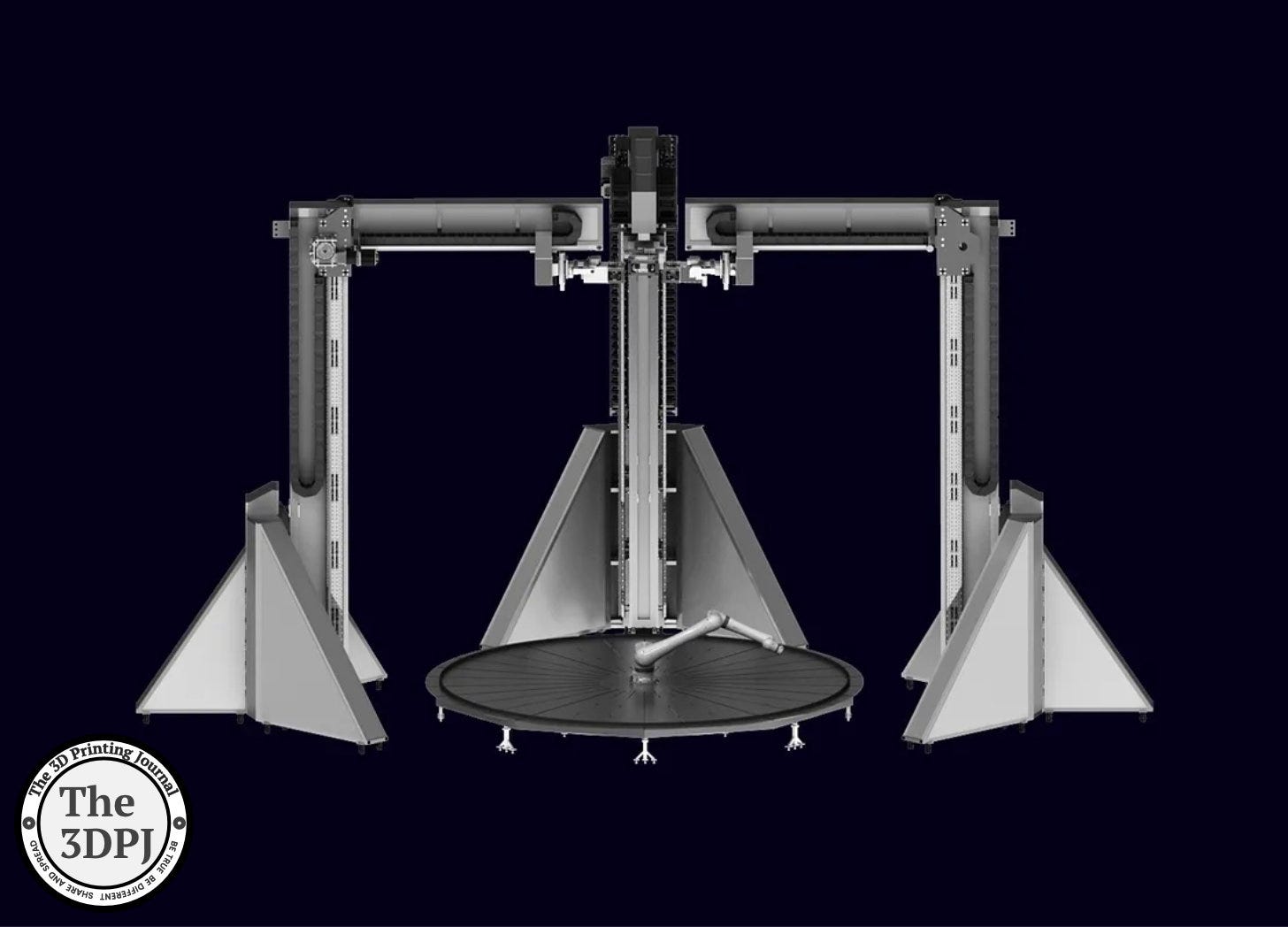

Rosotics, an Arizona-based American startup, has quickly captured the attention of the additive manufacturing industry. This success is due to their innovative platform, Halo, which produces metal parts by melting metals using three electromagnetic printheads installed on proprietary multi-axis gimbals. But that’s not all...

Yesterday, Christian LaRosa – founder and CEO of Rosotics – revealed that since 2020, his company has been developing the 'R2' spacecraft and its carrier, a 5-meter mothership to be launched on a SpaceX Starship. R2 will be tasked with building heavy infrastructure in orbit, and its services will be available to smaller providers.

One could argue that the innovative Halo was created partially for the needs of a much larger project. However, this is beneficial for the AM industry.

It turns out that Rosotics is not slowing down and has just announced another news – a collaboration with Siemens for the development of the “Next Generation Super-Heavyweight Platform” in Naval Manufacturing.

The companies have signed a Memorandum of Understanding (MoU) to develop and bring a “next generation, super-heavyweight class” platform that promises to revolutionize naval manufacturing and adjacent industries. It will be supported by Siemens' industry-leading architecture – Sinumerik One, known for its unparalleled precision and efficiency. The platform will be intelligent in nature and based on the Mjolnir 3D print architecture currently deployed on Rosotics’ commercial platform Halo.

Unfortunately, at this moment, we don’t know much more beyond these exciting announcements…

Rosotics describes the platform as “the most challenging production effort ever yet attempted in naval engineering, which is supposed to expand metal additive manufacturing to scales thought previously unattainable, setting entirely new standards for the industry.” The company even claims that the result of this collaboration will be a “significant milestone for all realms of manufacturing and will be (...) as profound as the first time steel was produced.”

Representatives of both companies commented on the partnership:

We are thrilled to work with Siemens on creating this remarkable architecture; their shared commitments to sustainable manufacturing and deep capabilities in complex kinematics will be paramount drivers of this endeavor. Their demonstrated heritage in renewable energy speaks volumes to us, and we do value it. We each carry optimism.

said Christian LaRosa.

Siemens is excited to join forces with Rosotics in this groundbreaking endeavor. The integration of Sinumerik One with Rosotics' advanced manufacturing system for this effort will create a platform of immense significance, capable of addressing the most complex production challenges in the naval industry.

described Siemens.

So, for now, that’s all. As I have heard many different promises in the area of additive manufacturing, I can only keep my fingers crossed and eagerly await the results of this fascinating collaboration.

The fact is that despite a short career in the AM industry (in terms of public career), Rosotics has captured everyone’s attention. Personally, I hope that its career will progress similarly to companies like Formlabs and not others from the Boston area... And that it won’t go public – that hasn’t ended well recently for companies in this sector…

Source: Rosotics press release