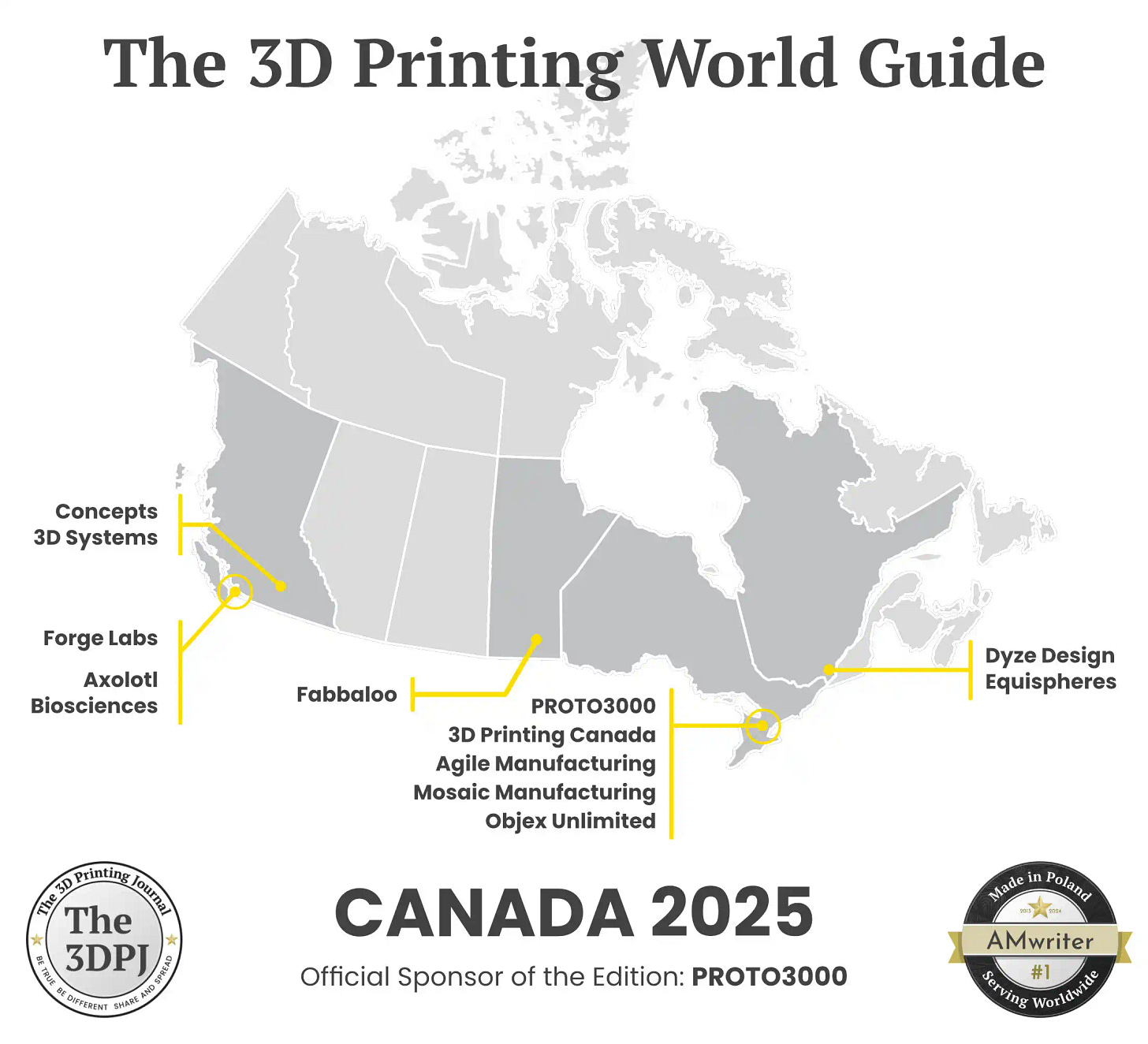

The following foreword is authored by esteemed Canadian AM writer and journalist, Mr. Kerry Stevenson, from the Fabbaloo.com portal.

The history of 3D printing in Canada has been little different from many other countries. During the 1980s, the initial technologies used were, of course, those from 3D Systems and Stratasys, SLA and FDM, respectively.

Systems from these companies, such as early Dimension gear, were typically installed in the engineering departments of universities for exploration and research.

However, it took much time for industry to catch on. Canada is a relatively conservative country, and many operations tend not to switch to something new unless someone else is doing it already. As students were exposed to the technology, they gradually filled the workforce, and business experiments with 3D printing began.

Click to download PDF version ⤓

I recall being at early informational sessions in the 2010 era, where the crowd was asked, “Who among us is using 3D printing?” And seeing few, if any, hands go up. While I was certain there were companies using the tech, the number of hands was far less than expected. The conclusion at the time was that the few who were 3D printing knew it could be a competitive advantage and didn’t want to let their competitors know they were up to something.

Many experiments failed, as they did in most countries, because businesses initially attempted simply reprinting existing designs that were not optimized for or leveraged 3D print technology. That phase took many years to overcome and is still a problem within some companies.

At this point, there were plenty of individuals on the loose that knew about the technology, and two things happened.

One was entrepreneurship, where several ventures sought to directly overcome issues in 3D printing that emerged after usage gradually increased in industry. One example would be AON3D, based in Montreal, which attempted to solve problems in 3D printing high-temperature materials.

Another venture was Precision ADM, based in Winnipeg, which launched a major metal 3D print service for companies unable to operate complex metal 3D printing infrastructure. A third might be Toronto-based Mosaic Manufacturing, which solved the multicolor desktop 3D printing problem with their unique Palette technology, and has now shifted their focus towards 3D print arrays.

The other effect was one of discovery. In Vancouver, friends attempting to produce better motorcycle parts developed more advanced FFF 3D print technology, which eventually transformed into Pantheon. 3DQue, also from Vancouver, discovered a way to automatically release prints from FFF 3D printers, which they later leveraged into a full-on 3D print farm cloud software service.

Proto3000: sponsor of the Canadian Edition of The 3D Printing World Guide

Today we see not only several key 3D print ventures like those mentioned above, but there is growing use of the technology in many industries, particularly aerospace. Prototyping is still a major use of the technology, but it’s clear that production of end-use parts in manufacturing is the road ahead.

On the desktop side, it’s now very common to see small 3D printers in homes, libraries, makerspaces, and other public places. It’s no longer the magic technology it was ten or fifteen years ago, as today’s highly automated desktop systems are increasingly purchased by non-technical individuals.

These will be used for hobbies, but also exploration of new ideas. We may very well see a wave of small ventures emerging that base their products on 3D printing in coming years.

by Kerry Stevenson (Fabbaloo.com)

Kerry Stevenson is Founder and Editor of Fabbaloo.com, website about Additive Manufacturing & 3D printing, created in October 2007. He’s been writing for Fabbaloo since it began under the gradually-becoming-less-mysterious pseudonym “General Fabb”

PROTO3000 | Proud Sponsor of Canadian Edition

Proto3000 Inc.

6260 Highway 7, Unit 8 Vaughan, Ontario, L4H4G3, Canada

Founded: 2007

www: proto3000.com

e-mail: info@proto3000.com

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

PBF

Distribution:

Formlabs

2oneLab

Desktop Metal

Keystone Industries

Scheftner Dental Alloys

Activity: North America

Overview:

Proto3000 Inc. provides end-to-end advanced manufacturing solutions that leverage design, additive manufacturing, and metrology to reduce product design cycles, enhance prototyping capabilities, improve production efficiency, and maximize supply-chain flexibility. The suite of 3D printing and 3D scanning products and services offered by the company enables customers to solve tough engineering and manufacturing challenges.

The product line of SLS, SLA, and DLP 3D printers, Desktop Metal 3D printers, Composite and Specialty Materials 3D Printers, including systems for wood 3D printing, Digital Sheet Forming, or Creaform portable handheld 3D scanners, along with the ISO9001-accredited service bureau, accelerates productivity, increases production speed, and makes manufacturing applications more efficient and cost-effective.

Proto3000 has supported customers in reinventing how they produce jigs and fixtures, prototypes, and tooling while creating opportunities to benefit from bridge tooling, low-volume production, supply chain reorganization, and on-demand digital inventory.

Legacy:

Proto3000 is a one-stop shop for Additive Manufacturing that encompasses everything from services, both on the engineering and dental side, as well as a reliable equipment provider starting from software to post-processing solutions. The strong knowledge of the industry held by this company helps customers become more efficient and productive in their manufacturing processes by adopting innovative methods.

Achievements in numbers:

1,000,000+ parts produced and shipped all over the world

1,000s of customers of all sizes

10,000+ completed products across all industries

30+ in-house industrial AM systems

Around 9 industrial AM processes offered.

3D PRINTING CANADA

3D Printing Canada (N3 Technologies Inc.)

36 Ditton Drive, Units #3-5, Hamilton, Ontario, Canada, L8W0A9

Founded: 2018

www: 3dprintingcanada.com

e-mail: contact@3dprintingcanada.com

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

Distribution:

BigRep

Modix

Caracol

Bambu Lab

Creality

Activity: Canada

Overview:

3D Printing Canada, operated by N3 Technologies Inc., is a trusted leader in Canada for 3D printing solutions. This company specializes in providing top-tier 3D printers, filaments, resins, 3D scanners, laser engravers, and parts & accessories. With a focus on quality, it caters to hobbyists, professionals, and businesses, offering reliable products and expert support. The extensive inventory ensures the perfect tools are available to bring ideas to life.

What sets this company apart? Competitive pricing, fast shipping, and unparalleled customer service. The knowledgeable team is always ready to assist with troubleshooting, product advice, and training. Whether exploring 3D printing for the first time or scaling up production, 3D Printing Canada delivers the expertise and tools needed. Visit 3dprintingcanada.com to discover the best in 3D printing technology today.

Legacy:

Founded with a passion for innovation, 3D Printing Canada quickly grew to become a trusted name in 3D printing solutions across the country. What makes the company unique is its unwavering commitment to quality, education, and customer success. From its early days as a small retailer to becoming one of Canada’s leading suppliers, 3D Printing Canada has always prioritized empowering creators and businesses with cutting-edge technology.

Company’s achievements include building one of the largest inventories of 3D printing products in Canada, offering same-day shipping, and providing hands-on technical support that sets us apart. It has partnered with schools, businesses, and makerspaces to drive education and innovation, and it’s community outreach programs have inspired countless creators to explore 3D printing.

By consistently delivering expertise and innovation, 3D Printing Canada has solidified its legacy as a pioneer in the industry, helping customers turn their ideas into reality.

AGILE MANUFACTURING

Agile Manufacturing Inc.

540 Mara Road Beaverton, Ontario Canada

Founded: 2004

www: agile-manufacturing.com

e-mail: Agile@Agile-Manufacturing.com

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

Distribution:

3D Systems

Markforged

Lynxter

Activity: North America

Overview:

Agile Manufacturing Inc. is Canada’s leader in 3D Printing and Additive Manufacturing. Operating from their advanced facility in North Toronto, the company house the nation’s largest fleet of cutting-edge 3D printing systems. In 2017, Agile Manufacturing expanded into the United States with a state-of-the-art center in Pella, Iowa, extending its services across North America.

Company’s capabilities include laser scanning, reverse engineering, 3D design, and rapid prototyping, supported by industry-leading technologies such as SLA, SLS, MJP, DMP, DLS, MJF, and FDM. Agile Manufacturing delivers unparalleled precision and speed, with same-day delivery services in the Greater Toronto Area to ensure projects stay on track.

As Canada’s top distributor of 3D Systems products, the company offers ProJet Multi Jet Printers alongside advanced Stereolithography and SLS solutions. Additionally, it is a leading distributor of Markforged’s industrial and desktop 3D printers, providing cutting-edge tools for rapid prototyping and production. In 2024, Agile Manufacturing became the master distributor for Lynxter Silicone 3D Printing technology across North America, further enhancing its product offerings.

With a commitment to innovation and excellence, Agile Manufacturing is the trusted partner for advanced manufacturing solutions.

Legacy:

Agile Manufacturing Inc. was founded by Richard Smeenk in 2004 to provide clients across Canada with access to advanced 3D printing technologies. Over the past 20 years, Agile has grown into an industry leader, operating from an 18,000-square-foot, purpose-built Additive Manufacturing center equipped with a fleet of over 50 production 3D printers. Agile is proudly ISO 9001:2015 certified and CGP registered, ensuring the highest standards of quality and security in every project.

AXOLOTL BIOSCIENCES

Axolotl Biosciences

3800 Finnerty Road Victoria, BC V8P 5C2, Canada

Founded: 2020

www: axolotlbiosciences.com

e-mail: willerth@axolotlbiosciences.com

social media: LinkedIn | Instagram

Business activities: Material Manufacturer

Activity: World

Overview:

Axolotl Biosciences is a women-led biotech startup founded in Victoria, BC, specializing in the production of high-quality bioinks for 3D bioprinting human tissue models. It’s flagship product, TissuePrint, as well as upcoming bioinks BrainPrint and HeartPrint, are designed to maintain over 90% cell viability. They support the differentiation of sensitive cells post-printing, including stem cells, neurons, and cardiac cells. These bioinks allow for the creation of more accurate human tissue models that can help advance current drug discovery and personalized medicine processes.

Axolotl’ bioinks are xeno-free, easy-to-use, and compatible with multiple bioprinting platforms- increasing accessibility and collaboration across a variety of research settings. Additionally, its products utilize Axolotl’s patented drug-releasing microsphere technology, which supports advanced tissue modeling through controlled cellular differentiation.

Legacy:

Axolotl is unique in its approach to bioink development, prioritizing the needs of cells over printability. Unlike conventional bioinks, Axolotl’s products are designed for long-term cell culture development, creating tissue models that closely mimic human physiology. This innovation allows researchers to achieve both accurate printing and biological functionality in their tissue models.

Key achievements include the launch of our flagship product, TissuePrint, in 2022, and the ongoing development of two future bioinks designed for neural and cardiac tissue modeling. Further, the drug-releasing microsphere technology used in our smart bioinks was recently awarded a patent. Axolotl has gained international recognition, winning awards at the Formnext and Falling Walls conferences in Germany, and being named a finalist in the Hello Tomorrow Global Challenge. As the only Canadian and one of two North American companies recognized at these conferences, we are proud to drive innovation in bioprinting.

CONCEPTS 3D SYSTEMS

Concepts 3D Systems Inc.

871 Stremel Rd. Kelowna, BC. Canada V1X5E6

Founded: 2022

www: concepts3d.ca

e-mail: nico@concepts3d.ca

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: Hardware Manufacturer

AM services:

SLA / DLP

Distribution:

Concepts 3D – Athena and Athena II Smart mSLA Resin 3D Printers

Activity: World

Overview:

Concepts 3D Systems is a leader in the development of high-performance mSLA resin 3D printers for consumers, prosumers and professionals. Known for their precision, durability, and innovative features, the company’s printers are designed to meet the needs of both advanced users and businesses. Their flagship Athena series stands out for its groundbreaking force sensor technology, modular architecture, and unmatched upgradability, ensuring users can customize and expand their machines to meet evolving requirements.

Concepts 3D Systems prioritizes user-friendly designs and cutting-edge technology, creating printers that deliver exceptional accuracy and reliability. By engaging directly with its growing community of users, the company continuously improves its products to stay at the forefront of the industry. With the launch of Athena II, Concepts 3D Systems reaffirms its commitment to redefining resin 3D printing, offering solutions that combine innovation, scalability, and long-term value.

Legacy:

Founded by Nico Martin, Concepts 3D Systems has a rich history of innovation in mSLA resin 3D printing. Nico began developing this technology in 2012, building one of the first working prototypes using monochrome LCDs. Over the next decade, he designed more than 30 printers, ranging from large-format industrial machines to compact consumer models.

In 2020, Nico partnered with Pascal Wistinghausen to develop open-source electronics for resin 3D printers under the Athena name. Their collaboration laid the foundation for the company's focus on advanced technology and user-centric design.

Incorporated in 2022, Concepts 3D Systems launched the Athena Smart mSLA printer, achieving its Kickstarter funding goal in under 30 minutes. By 2024, the company expanded its offerings with Athena II, a community-driven printer that set new standards for modularity and performance. Together, Nico and Pascal continue to lead Concepts 3D Systems in shaping the future of resin 3D printing.

DYZE DESIGN

Dyze Design Inc.

1505 Saint-Thomas Suite 100, LeMoyne, (Montreal), Quebec, Canada

Founded: 2015

www: dyzedesign.com

e-mail: info@dyzedesign.com

social media: LinkedIn | Facebook | YouTube

Business activities: Hardware Manufacturer

AM services:

FDM / FFF

Activity: World

Overview:

Dyze Design is a global leader in advanced hardware for industrial and large-format 3D printing. Specializing in extrusion systems, motion controllers, and high-performance components, our products are engineered to meet the most demanding manufacturing needs. From high-flow & large-scale pellet extruders to state-of-the-art motion IO control solutions, Dyze Design delivers tools that enable faster, more reliable, and precise additive manufacturing processes, for real-life production applications.

Dyze Design’s offerings stand out for their robustness, ease of integration, and compatibility with challenging materials like carbon-fiber composites and engineering-grade thermoplastics. This makes the company the partner of choice for industries such as aerospace, medical, construction, and automotive.

Driven by a commitment to innovation and customer success, Dyze Design continually redefines industry standards. Its focus on R&D and user-centric design ensures our solutions empower manufacturers to scale production efficiently while maintaining exceptional quality, unlocking new possibilities in industrial-grade 3D printing.

Legacy:

Founded in 2015 in Montreal, Canada, Dyze Design has built a strong reputation for innovation and excellence in additive manufacturing since its inception. Starting as a small team of engineers, it quickly gained recognition for solving some of the industry's most complex challenges, including high-flow material extrusion for large format 3d printing and advanced motion control to unlock digital twin capabilities and provide just-in-time 3D printed parts validation and certification.

Dyze Design’s flagship products, such as the Pulsar high-flow pellet extruder and the Typhoon high-flow filament extruder, are used worldwide to produce large-scale, production parts. These technologies are celebrated for their ability to handle high-throughput production while maintaining material integrity and dimensional accuracy.

Over the years, Dyze Design has earned numerous honors, including being 2 times finalist in the prestigious TCT Awards for our Pulsar pellet extruder and later for our Pulsar Atom small scale pellet extruder. Today, our products are trusted by leading OEMs and manufacturers, demonstrating our lasting impact on the 3D printing landscape.

Dyze Design’s legacy is one of innovation, reliability, and transformative industrial solutions.

EQUISPHERES

EQUISPHERES Inc.

500 Palladium Dr #4100, Stittsville, ON K2V 1C2, Canada

Founded: 2015

www: equispheres.com

e-mail: info@equispheres.com

social media: LinkedIn

Business activities: Material Manufacturer and AM Service Provider

AM services:

PBF

DED / WAAM

BinderJetting

Distribution:

Cast Aluminum alloys

Additive Aluminum alloys

Next Gen Aluminum alloys for AM

Additive Copper alloys

Activity: World

Overview:

Equispheres is a technology company focused on enabling mass production with Additive Manufacturing. From cost-to-manufacture through to the capabilities and reliability of the final parts, materials play an out-sized role in deciding how far additive manufacturing can really go.

Equispheres developes technologies and products specific to additive manufacturing materials. Equispheres' proprietary technology produces highly spherical powders with smooth surfaces, controlled powder size, and without fines. Equispheres' materials allow customers to achieve both high packing density and high energy absorption, resulting in better mechanical properties while also allowing for faster build speeds and consistent, repeatable results.

Equispheres is partnering with companies scaling their AM programs up to serial production.

Legacy:

Equispheres has developed a proprietary powder production technology that enables the modification and management of powder properties. Company’s engineers have designed a line of powder products that allows customers to maximize the power and scanning speeds of their printers and to produce parts at full speed, more reliably and economically.

In addition to supplying the AM industry with best in class aluminum powders, EQS is looking to the future with development of NExP1, a non-explosive LPBF aluminum powder, and a sinterable aluminum powder capable of being used in binderjet and other sinter-based process.

Equispheres continues to lead the industry in achieving greater productivity through combining powder design with kilowatt class lasers and multi-kilowatt beam shaping lasers. Supporting its strategic partners as the push the limits on machine productivity and part performance.

FABBALOO

Fabbaloo

3rd Floor, 125 Adelaide St, Winnipeg MB Canada R3A 0W4

Founded: 2007

www: fabbaloo.com

e-mail: info@fabbaloo.com

social media: LinkedIn

Activity: World

Overview:

Fabbaloo publishes news and analysis of the 3D print industry, covering advanced research, industrial and professional use, as well as desktop and personal technologies. The portal interview those involved in the industry and attend industry events to gather the most current information for its analysis. And it is particularly fond of startup companies building on new technologies and concepts.

Legacy:

Fabbaloo was launched in Fall 2007, becoming perhaps the first online publication dedicated to covering the industry. While its initial posts were infrequent, today Fabbaloo publishes 20-25 stories per week on all related topics and technologies. The portal frequently review 3D printers and related equipment, such as 3D scanners, and today has published well over 100 product reviews. Fabbaloo has produced close to 16,000 posts over the years, representing well over 6M words. As its founder Kerry Stevenson says - “We've seen companies launch, fail, and everything in-between.”

FORGE LABS

Forge Labs Inc.

101-8337 Eastlake Drive, Burnaby BC, V5A 4W2, Canada

Founded: 2014

www: forgelabs.com

e-mail: sales@forgelabs.com

social media: LinkedIn | Instagram | YouTube

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

PBF

BinderJetting

Activity: North America

Overview:

Forge Labs is Canada’s premier 3D printing and advanced manufacturing company, specializing in high-quality, industrial-grade parts for a wide range of industries. Since its founding in 2014, the company has grown from a small operation in Vancouver to a state-of-the-art facility serving clients across Canada and the United States. Forge Labs' 3D prints have transformed nearly every major Canadian industry.

The company has brought to life props, costumes, and set pieces featured in blockbuster TV shows and films made in Hollywood North. It has produced life-saving medical devices and ventilators to support Canadians during the pandemic and has created lighter, more efficient parts for the automotive and aerospace sectors. Even the iconic Tim Hortons coffee lid—a hallmark of Canadian culture—was redesigned with the help of Forge Labs.

Legacy:

Forge Labs was the first Canadian company to launch a custom-built digital manufacturing platform, revolutionizing how businesses access advanced manufacturing services. The company’s platform streamlined the quoting and ordering process, enabling customers to upload CAD files and receive instant, accurate pricing and lead times—faster than any other bureau in North America.

By seamlessly integrating its digital platform with in-house manufacturing technology, Forge Labs maintained full control over its entire supply chain. With all production managed under one roof, the company meticulously tracked quality at every stage while ensuring the fastest possible turnaround times. Through its proprietary software, Forge Labs eliminated inefficiencies and created a workflow that delivered unmatched reliability, consistency, and speed.

MOSAIC MANUFACTURING

Mosaic Manufacturing Inc.

111 Peter Street, Unit 403 Toronto, ON M5V 1H1 Canada

Founded: 2014

www: www.mosaicmfg.com

e-mail: alexandra@mosaicmanufacturing.com

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: Hardware Manufacturer, Material Manufacturer and AM Service Provider

AM services:

FDM / FFF

Distribution:

Array

Element

Activity: World

Overview:

Mosaic is reshaping supply chains with scalable solutions powered by additive manufacturing. Founded in 2014 and headquartered in Toronto, the company’s factory-connected products reduce the total cost per part by combining reliable automation with intelligent software for enhanced, lights-out manufacturing.

As a strategic partner, Mosaic accelerates the deployment of digital on-demand inventory systems, simplifying operations, minimizing labor, and improving responsiveness to market demands. The company’s patented 3D printing technology provides a significant edge over traditional methods, enabling a more streamlined and sustainable future.

Legacy:

Mosaic Manufacturing stands out as a leader in automated additive manufacturing, offering scalable solutions that transform supply chains through localized, on-demand production. The company’s patented technology, including the Array platform and Element printer, integrates automation, intelligent software, and material flexibility to deliver high-quality, cost-effective parts with minimal manual intervention. What sets Mosaic apart is its end-to-end approach, combining expertise, innovative hardware, and powerful software like Canvas to optimize production workflows.

Founded in 2014, Mosaic achieved significant milestones, including pioneering multi-material 3D printing with Palette (now integrated into its Array and Element solutions as the PaletteX material management system) and raising $28 million to drive supply chain resilience. From reshoring production to enabling digital inventory, Mosaic is reshaping how and where the world manufactures.

OBJEX UNLIMITED

Objex Unlimited Inc.

2140 Dunwin Drive, Mississauga, Ontario, Canada L5L 1C7

Founded: 2011

www: objexunlimited.com

e-mail: sales@objexunlimited.com

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

BinderJetting

Distribution:

3D Systems

Mimaki

Luxcreo

Artec 3D

EXT 800 Titan Pellet

Activity: North America

Overview:

Objex Unlimited is a 3D solutions provider and Canadian equipment reseller, specializing in 3D Printing, 3D Scanning, and 3D Design Services. The company’s full in-house service bureau offers customers a one-stop shop for everything 3D, delivering products and services that span an array of industries for various applications.

Combining cutting-edge technology, art, and engineering, Objex Unlimited designs and produces highly detailed physical models, rapid prototypes, concept models, end-use production parts, and outstanding unique personalized products. The company brings CAD designs to life by creating real parts that can be used and models that can be held in hand.

Prototype production is not allowed to hold up the design cycle at Objex Unlimited. When the company promises rapid, it delivers rapid. Its commitment is to deliver within days. Whether it 3D prints CAD designs or works with customers through the concept development stage, Objex Unlimited offers a high level of quality, service, and integrity.

Legacy:

Founded over a decade ago, Objex Unlimited has established itself as a trusted leader in 3D solutions across Canada, blending engineering, art, and design. Renowned for excellence in 3D colour printing, the company delivers high-quality, precise results for industries including display, creative agencies, film, props, and industrial design. Specializing in 3D scanning-to-print solutions, Objex Unlimited transforms real-world objects into flawless digital models for accurate reproduction.

Through its Selftraits brand, the company provides world-class 3D printed figurines, turning personalized creations into reality. With a fully equipped in-house service bureau, Objex Unlimited ensures precision, creativity, and rapid turnaround at every stage, offering end-to-end solutions from concept to completion.

As an authorized reseller of top-tier 3D technology, Objex Unlimited continues to push the boundaries of innovation, driven by a legacy of quality, expertise, and a relentless pursuit of perfection. Today, the company remains a cornerstone of professional 3D solutions for complex projects in Canada.