The following foreword is authored by esteemed German AM consultant, Mr. Johannes Lutz, from the 3D Industrie consulting.

Anyone who was already using 3D printing around the turn of the millennium, back when it was still called "rapid prototyping," belonged to a very small group of companies that had access to this technology. How quickly and easily prototypes could be created back then was often kept a closely guarded secret.

This was the case around 2009, when SLA and SLS components were still traded like gold. If a similarly large component costs 300 to 400 euros today, the price back then was about 5,000 euros. There was little competition, and it was lucky to know someone who mastered the technology.

Click to download PDF version ⤓

In the years that followed, especially in 2013, the hype around 3D printing ignited the right zeitgeist. Manufacturers like EOS, Concept Laser, and SLM Solutions shaped innovations in metal 3D printing, while companies like GermanRepRap and BigRep helped bring FDM printers into development and design departments across Germany.

As new manufacturers emerged in other countries, the 3D printing service market continued to grow, and the benefits for industrial companies expanded. However, after 2022, the peak seemed to have passed. Many companies already owned 3D printers, and the economic situation in Germany changed.

Fiberthree: sponsor of the German Edition of The 3D Printing World Guide

The country, once one of the largest consumers of 3D printing, fell behind. The next step in development was hindered by a lack of investment and, in some cases, poor experiences with the technology.

Today, many companies use 3D printing successfully, while others still ignore the technology. The "German technology fear" remains an obstacle that has not yet been overcome.

by Johannes Lutz (3D Industrie)

Johannes Lutz is the managing director of 3D Industrie, and previously, he was the founder of Mark3D – a leading European distributor of industrial 3D printers. Since 2019, through 3D Industrie, he has been helping medium-sized companies entering AM business. Lutz is the author of the book "3D Printing Professional Knowledge" and publishes a weekly podcast on 3D printing.

FIBERTHREE | Proud Sponsor of German Edition

Fiberthree GmbH

Otto-Hesse-Straße 19, 64293 Darmstadt, Germany

Founded: 2017

www: fiberthree.de

e-mail: contact@fiberthree.com

social media: LinkedIn | Instagram | YouTube

Business activities: Material Manufacturer

AM services:

FDM / FFF

Distribution:

Fiberthree filaments

F3 PA-CF Pro

F3 PA ESD

F3 PA-GF30 Pro

F3 Dry Box

Activity: World

Overview:

Fiberthree develops and sells high-performance technical filaments. Starting with a PA, the range includes also PC, PP, all filled with carbon or glass fiber. The latest products are a PA with ESD properties and a transparent PA for prothesis. Besides the material, Fiberthree offers service production for local customers on FFF-machines upto 1m³.

Legacy:

Founded in 2017, Fiberthree started as an engineering office, and due to no better solutions went all the way back in the value-chain to produce own compunds for industrial 3d-printing on almost any open printer. Today Fiberthree offers all products, from pellets, to filament, to printed parts.

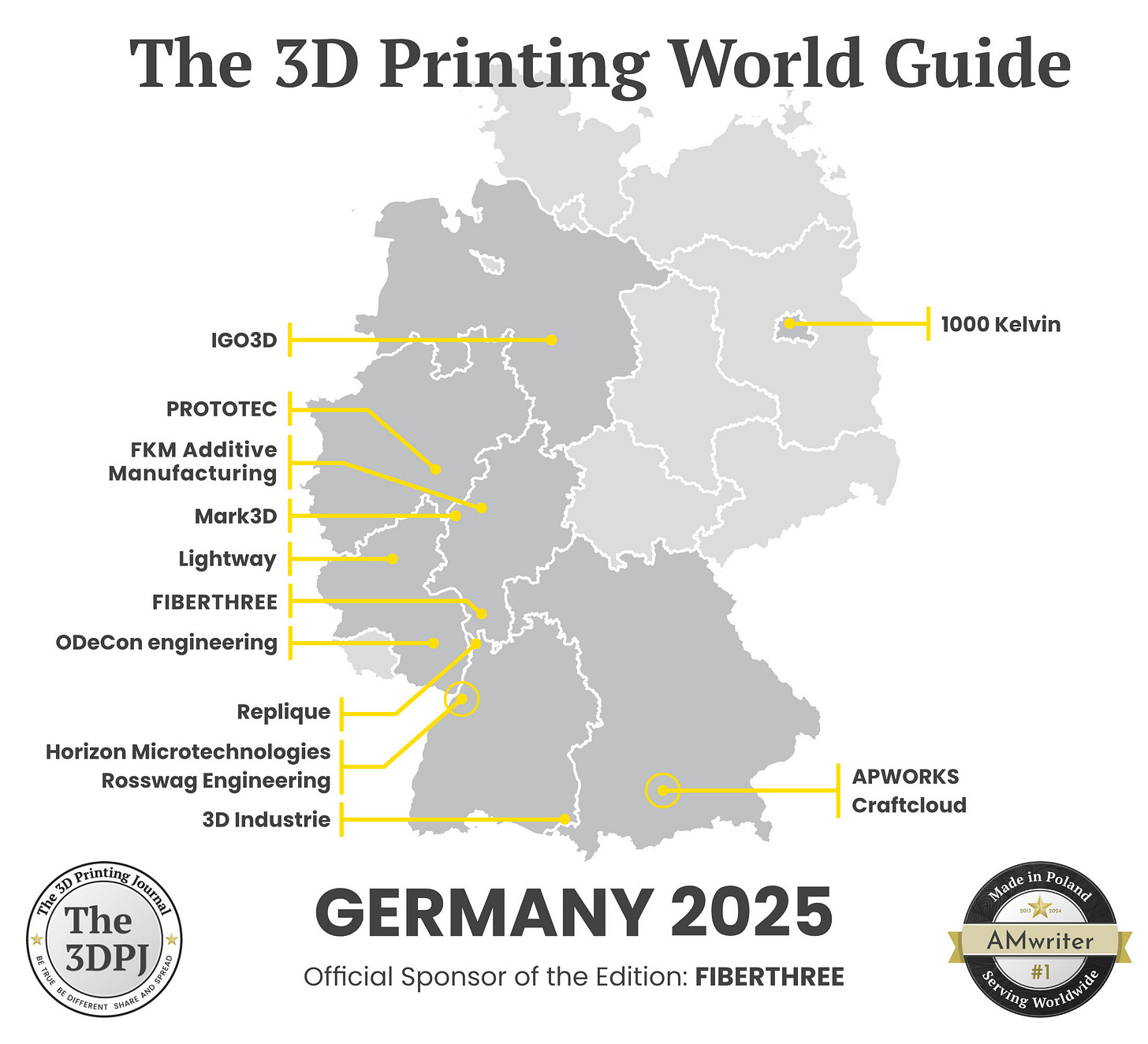

1000 KELVIN

1000 Kelvin GmbH

Bismarckstrasse 10-12, 10625 Berlin, Germany

Founded: 2022

www: 1000kelvin.com

e-mail: info@1000kelvin.com

social media: LinkedIn

Business activities: Software developer

AM services:

PBF

DED / WAAM

Activity: Europe

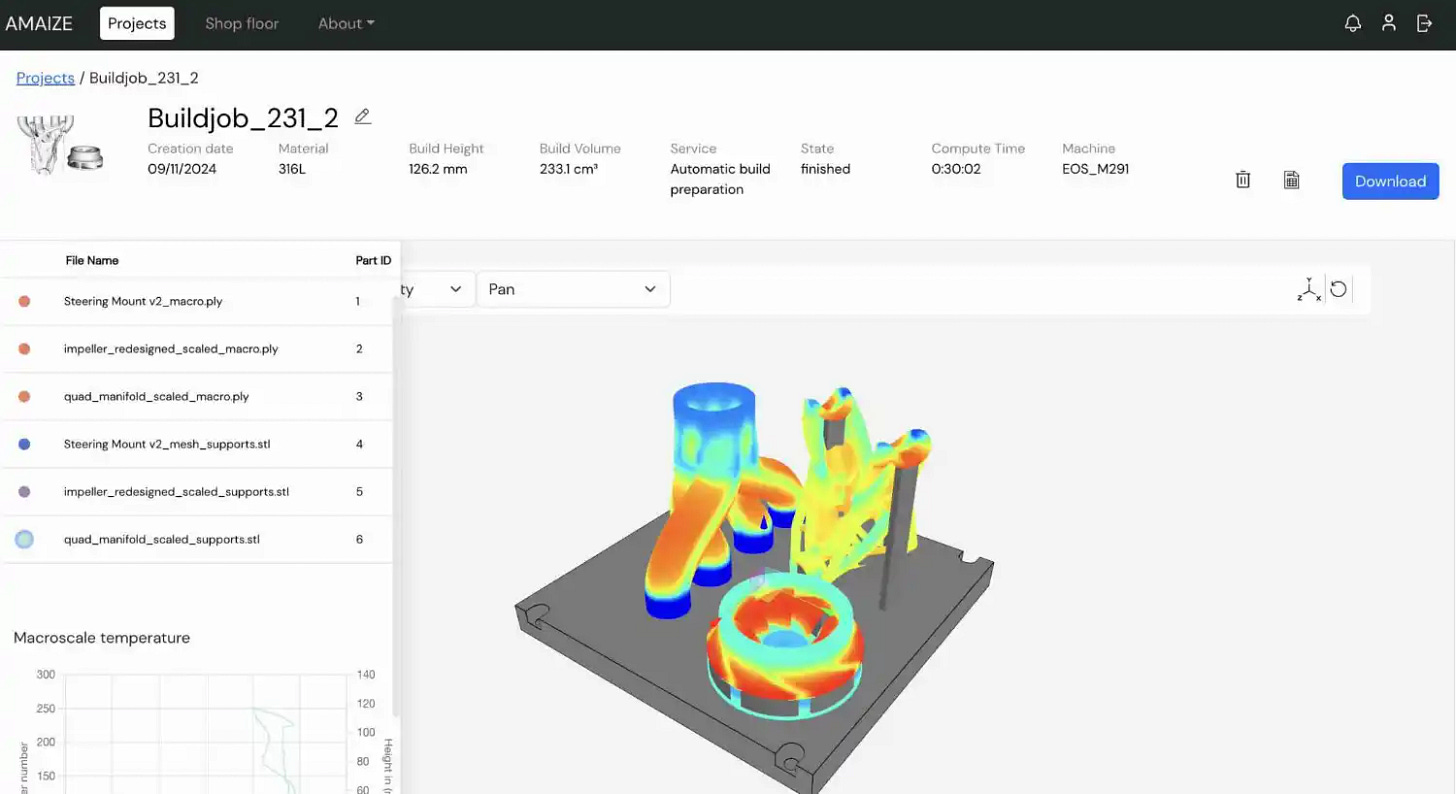

Overview:

1000Kelvin enables companies using additive manufacturing in production to get qualified parts to market faster at a lower cost.

1000Kelvin’s AI software AMAIZE uses Physics AI models to :

Automated analysis of your parts with AMAIZE’s AI to determine printability

Automated build preparation you can have confidence in, with optimized exposure strategy

A solution that helps you quote and do faster build preparation, ensuring you stay competitive.

Legacy:

First and only end to end AI company offering commercially available AI copilot. Founded by physicist and mathematician and serial entrepreneurs with track record in developing, commercialising and exiting AI technologies.

3D INDUSTRIE

3D Industrie GmbH

Händelstraße 3, 88450 Berkheim, Germany

Founded: 2019

www: 3dindustrie.de

e-mail: jl@3dindustrie.de

social media: LinkedIn | YouTube

Business activities: Consulting, Publishing (podcast)

Activity: Germany

Overview:

3D Industries supports manufacturing and industrial companies in successfully implementing 3D printing within their operations. This includes finding applications, increasing acceptance for 3D printing within the company, and making a technology decision. The goal of the company is to ensure that 3D printing saves time and money in the right areas and strengthens innovation. With 3D Industries’ specially developed method for 3D printing applications, the potential for 3D printing can be identified quickly and easily.

Through consulting, 3D Industries assists 3D printing service providers in Germany, Austria, and Switzerland in acquiring more premium customers, high-quality projects, and small-series parts. Additionally, the company supports them with various other questions regarding the business field and strategic direction to boost revenue and productivity in parts manufacturing. Over 130 3D printing service providers now trust 3D Industries’ expertise.

Legacy:

Johannes Lutz was already active in technical sales and application development for 3D printing alongside his studies in mechanical engineering and economics, and then founded the company Mark3D GmbH in 2016. He focused specifically on the sales of 3D prints for tools and fixtures.

Since the 3D printing technology was unknown at the beginning and applications for components were difficult to justify, he decided to do everything necessary to convince companies of the benefits of 3D printing, enabling them to successfully print parts and thus save time and money while becoming more innovative.

As the consulting demand for 3D printing grew, he made the decision to position himself more clearly in this area and founded 3D Industrie GmbH in 2019.

Today, he helps small and medium-sized enterprises successfully start with 3D printing and helps 3D printing service providers receive orders more quickly and easily. Johannes Lutz is the author of the book 3D Printing Expert Knowledge and releases a new 3D printing podcast episode every Tuesday.

APWORKS

APWORKS GmbH

Willy-Messerschmitt-str. 1, 82024 Taufkirchen, Germany

Founded: 2013

www: apworks.de

e-mail: info@apworks.de

social media: LinkedIn

Business activities: AM Service Provider

AM services:

PBF

Activity: World

Overview:

APWORKS is a leader in the application of metal additive manufacturing in high performance and safety critical applications. Combining design engineering with manufacturing and materials science capabilities, they have supported hundreds of customers worldwide in bringing AM into their products. They also commercialised the Scalmalloy high strength Aluminium alloy which is now also licensed to other companies and used extensively in Motorsport and spacecraft applications.

Legacy:

The combination of Engineering and Manufacturing in one team enabled APWORKS to overcome a key barrier to adoption of AM, which is the proper application of design for process. The introduction of Scalmalloy, the first material truly tailored to AM processing, will likely be the most impactful for the industry into the future, as its adoption continues to grow in motorsport, aerospace and sporting goods segments.

CRAFTCLOUD

Craftcloud (All3DP GmbH)

Ridlerstraße 31A, 80339 München, Germany

Founded: 2016

www: craftcloud3d.com

e-mail: support@craftcloud3d.com

social media: LinkedIn | Facebook

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

PBF

BinderJetting

Activity: World

Overview:

Craftcloud is a fully transparent 3D printing marketplace. We connect both small and large 3D printing service providers with customers from all over the world. Our goal is to make 3D printing accessible, affordable and easy to everyone!

Legacy:

Started as a price comparison service, but has since evolved into one of the only transparent marketplaces in the industry. We strive to be the best platform for customers and our Trustpilot rating speaks volumes for how far we have come when it comes to customer satisfaction in this growing industry: trustpilot.com/review/craftcloud3d.com

FKM ADDITIVE MANUFACTURING

FKM Additive Manufacturing (FKM Sintertechnik GmbH)

Zum Musbach 6, 35216 Biedenkopf, Germany

Founded: 1994

www: fkm.net

e-mail: info@fkm.net

social media: LinkedIn

Business activities: AM Service Provider

AM services:

SLS

MJF

PBF

Activity: World

Overview:

FKM is completely specialized in additive manufacturing of ready-to-use parts, such as serial parts, spare parts, functional prototypes and tools directly from 3D data. As a full-service provider, FKM offers comprehensive solutions encompassing materials consulting, design optimization by co-engineering, ensuring each component is meticulously tailored to client specifications.

Focusing on advanced additive manufacturing technologies, including Selective Laser Sintering (SLS) for plastics and Selective Laser Melting (SLM) for metals, FKM delivers high-quality, ready-to-install parts. The extensive in-house capabilities feature a wide selection of high-quality plastic and metal materials, as well as a variety of surface finishing options. This enables the production of both large components and substantial quantities within short timeframes.

Legacy:

Founded in 1994, FKM is a pioneer in Powder-Bed-Fusion (PBF) for plastic and metal, specializing exclusively in this advanced 3D printing production principle.

Starting 30 years ago with the first commercial used SLS-machine in Germany and now operating one of Europe’s most modern powder bed fusion facilities in Biedenkopf, FKM’s 4,000 m² factory houses 47 industrial systems. Supported by a dedicated team of 60 employees, FKM successfully produces series parts, prototypes and spare parts from plastic and metal, completing over 11,000 orders annually.

Certified to ISO 9001, ISO 14001, and IATF 16949 standards, FKM ensures the highest quality and environmental responsibility. This combination of advanced technology, production capacity, and industry-leading expertise makes FKM a trusted partner in the 3D printing industry, offering reliable and innovative solutions for a wide range of applications and customers.

HORIZON MICROTECHNOLOGIES

Horizon Microtechnologies GmbH

Silberstreifen 4, 76287 Rheinstetten, Germany

Founded: 2021

www: 3dmicrofabrication.com

e-mail: info@3dmicrofabrication.com

social media: LinkedIn

Business activities: AM Service Provider

AM services:

SLA / DLP

Activity: World

Overview:

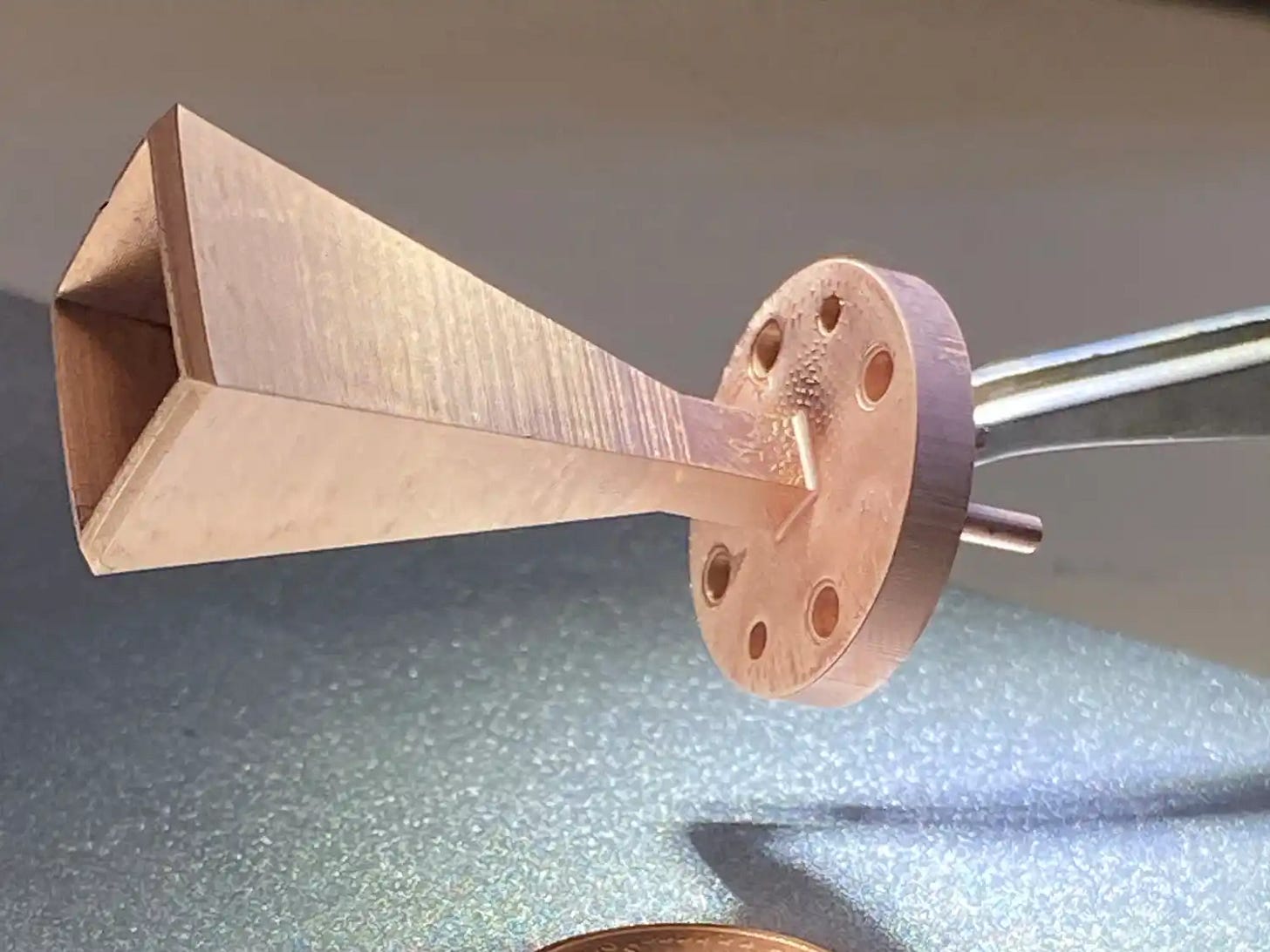

Horizon Microtechnologies offers product development and contract manufacturing services for hightech customers across various industries. Its in-house process technologies leverage photopolymer-based additive manufacturing with 10 µm precision and post-build coating processes which, together, allow to create precision-engineered and miniaturized products with a high degree of functional integration.

On one hand, the print material selection is suited to address applications requiring high precision, high-temperature resistance, low thermal expansion and biocompatibility. On the other hand, the coating processes allow the homogeneous deposition of metals such as copper and silver, resistive layers as well as metal-oxide based protective coatings to insulate the part from the environment or vice verse.

Together, the printing and processing technologies are a "best of both worlds" approach, combining the precision, design freedom and repeatability of photopolymer based 3D printing and the beyond-polymer functionalities contributed by the coatings.

Applications and customers served are in electronics, test&measurement, aerospace and medicine.

Legacy:

Founded in late 2021, Horizon Microtechnologies has pioneered a suite of coating processes explicitely designed for usage with 3D printed parts and the complex geometries and material science aspects these typically feature. Since its inception, it has systematically driven this technology into micro- and mm-wave applications.

Here, the design freedom and lightweight characteristics of 3D printed polymer parts together with highly conductive coatings directly translate into size- and weightsaving components that often even have superior functionality than metallic counterparts, which especially benefits on-the-move and space applications.

Recently, the manufacturing processes have become sufficiently mature and standardized to offer certain components such as horn antennas as off-the-shelf digital models that are produced on demand with very short lead times and near to no extra efforts for small customizations.

IGO3D

IGO3D GmbH

Vahrenwalder Str. 315A, 30179 Hannover, Germany

Founded: 2013

www: igo3d.com

e-mail: info@igo3d.com

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

Distribution:

UltiMaker

Formlabs

Bambu Lab

BigRep

Intamsys

Activity: Europe

Overview:

IGO3D GmbH is one of Europe’s leading distributors and service providers for 3D printing technologies and digital manufacturing solutions. Headquartered in Hanover, Germany, the company specializes in providing professional and desktop 3D printers, consumables, and accessories for businesses, educational institutions, and makers.

With a strong focus on customer service, IGO3D offers expert consulting, training, installation, and after-sales support, ensuring seamless integration of additive manufacturing into various industries. The company collaborates with top global manufacturers, maintaining high product availability and competitive pricing.

IGO3D’s vision is to become Europe’s largest platform for 3D printing and digital fabrication, supporting local production, customization, and sustainability. Through strategic partnerships, a growing reseller network, and an expanding service portfolio, the company continues to drive innovation and accessibility in the 3D printing market.

For more information, visit IGO3D’s website.

Legacy:

Founded in 2013, IGO3D GmbH was one of the first companies in Europe to specialize in 3D printing distribution. Starting as a pioneer in desktop 3D printing, the company quickly expanded to professional and industrial solutions, serving businesses, universities, and makers.

What makes IGO3D unique is its comprehensive ecosystem—combining product distribution, expert consulting, training, and after-sales service. With over 50 employees and a dedicated logistics center, the company ensures high product availability and fast delivery across Europe. Its deep market knowledge, strong manufacturer relationships, and ability to scale have made it a trusted partner in the industry.

Key Achievements:

Repeatedly ranked among Germany’s fastest-growing companies

Operator of Germany’s most popular online shop for 3D printers

Recognized multiple times as a top distributor by leading manufacturers

Established local structures with sales teams, showrooms, field service engineers, and application engineers across key regions

Strong reseller network covering DACH & EU markets.

LIGHTWAY

Lightway GmbH

Klemens-Jeub-Str 3, 56651 Niederzissen, Germany

Founded: 2016

www: lightway.de

e-mail: j.hoetter@lightway.de

social media: LinkedIn | Facebook | Instagram

Business activities: AM Service Provider

AM services:

PBF

Activity: World

Overview:

As an innovative full-service solution provider in the field of 3D metal printing and high-end CNC machining, LIGHTWAY develops customized solutions and highly complex metal components with utmost precision. The company's specialization extends beyond selective laser melting, making its portfolio much broader than additive manufacturing alone. If desired, LIGHTWAY manages the entire process chain, from engineering through production to the finished component.

Whether it’s 3D metal printing, pure machining, or a combination of both, LIGHTWAY approaches challenges with solutions and selects the most efficient manufacturing method for its demanding components. The company's focus remains on complex parts, which can be produced even in small quantities through automation. Special materials like titanium or invar pose no problem for LIGHTWAY.

LIGHTWAY analyzes the entire process with the goal of further optimizing the components it manufactures by adding extra value. The company's expertise in designing and fabricating complex three-dimensional metal components sets it apart, making it a competent partner in fields such as mechanical engineering, medical technology, automotive, optics, or even laser technology.

Specializing in advanced solutions within 3D metal printing, LIGHTWAY creates intricate or topology-optimized geometries that can combine multiple functions—such as cooling, heating, or integrating additional media. The company also handles complete powder and material development, including parameter optimization, heat treatment, and the corresponding certification and qualification processes for materials and components. In the realm of conventional machining, LIGHTWAY focuses on delivering high-quality results.

Legacy:

LIGHTWAY GmbH, founded in 2016 by Thomas Hilger and Pascal Schäfer, is a German company specializing in additive manufacturing and high-end CNC machining. The founders, both experienced in mechanical engineering, began exploring additive manufacturing technologies in 2012, leading to the establishment of LIGHTWAY.

The company offers comprehensive services, including engineering, additive manufacturing using Powder Bed Fusion (PBF-LB/M), material development, CNC machining, post-processing, and quality assurance. Their expertise caters to various industries, such as automotive, aerospace, and medical technology.

In 2022, LIGHTWAY expanded its production facilities by adding a new hall to accommodate growth and enhance digitalization efforts. The same year, the company received the Innovation Award of Rhineland-Palatinate in the "Handwerk" category for developing an intelligent, modular valve housing produced via 3D metal printing.

LIGHTWAY's commitment to innovation and quality has solidified its reputation as a reliable partner in the field of advanced manufacturing technologies.

MARK3D

Mark3D GmbH

Rodenbacher Strasse 15, 35708 Haiger, Germany

Founded: 2016

www: www.mark3d.de

e-mail: markforged@mark3d.de

social media: LinkedIn | Facebook | Instagram | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM/FFF

Distribution:

Markforged

Activity: Europe

Overview:

Mark3D is the award-winning Markforged reseller of high-end 3D printers. The company supplies, installs, and supports the full range of Markforged printers, as well as their print materials, software, and accessories throughout Germany, Austria, Switzerland, Benelux, and the UK. Focusing exclusively on the Markforged range of 3D printers, Mark3D also brings subject matter expertise with strong in-house CAD and engineering design skills.

Mark3D helps customers use Markforged 3D printers to find the best solutions for their requirements by providing professional support from the initial idea to the finished product in terms of 3D printing.

This ensures that customers can print in carbon fibre or metal quickly, efficiently, and competitively, enabling them to make better decisions while designing and developing their products.

The company’s core business focuses on the sale and support of Markforged 3D printers, print materials, software, and accessories, as well as consulting in the additive manufacturing of strength-critical functional components and 3D printing of fibre-reinforced pattern components.

Legacy:

Mark3D is a company specializing in additive manufacturing solutions. As a partner of Markforged, Mark3D distributes the entire product portfolio of this 3D-printing pioneer across Europe. Markforged, based in Massachusetts, is renowned for its innovative approach to industrial 3D printing, especially in the areas of continuous fiber reinforcement (CFR) and metal 3D printing.

Mark3D was founded to support businesses in leveraging Markforged's cutting-edge technology, which is unique due to its ability to combine advanced materials like carbon fiber, Kevlar, fiberglass, and even metal powders for functional parts. This capability sets Mark3D apart from many other additive manufacturing providers.

ODECON ENGINEERING

ODeCon engineering GmbH

Hertelsbrunnenring 2, D-67657 Kaiserslautern, Germany

Founded: 2020

www: odecon.de

e-mail: info@odecon.de

social media: LinkedIn

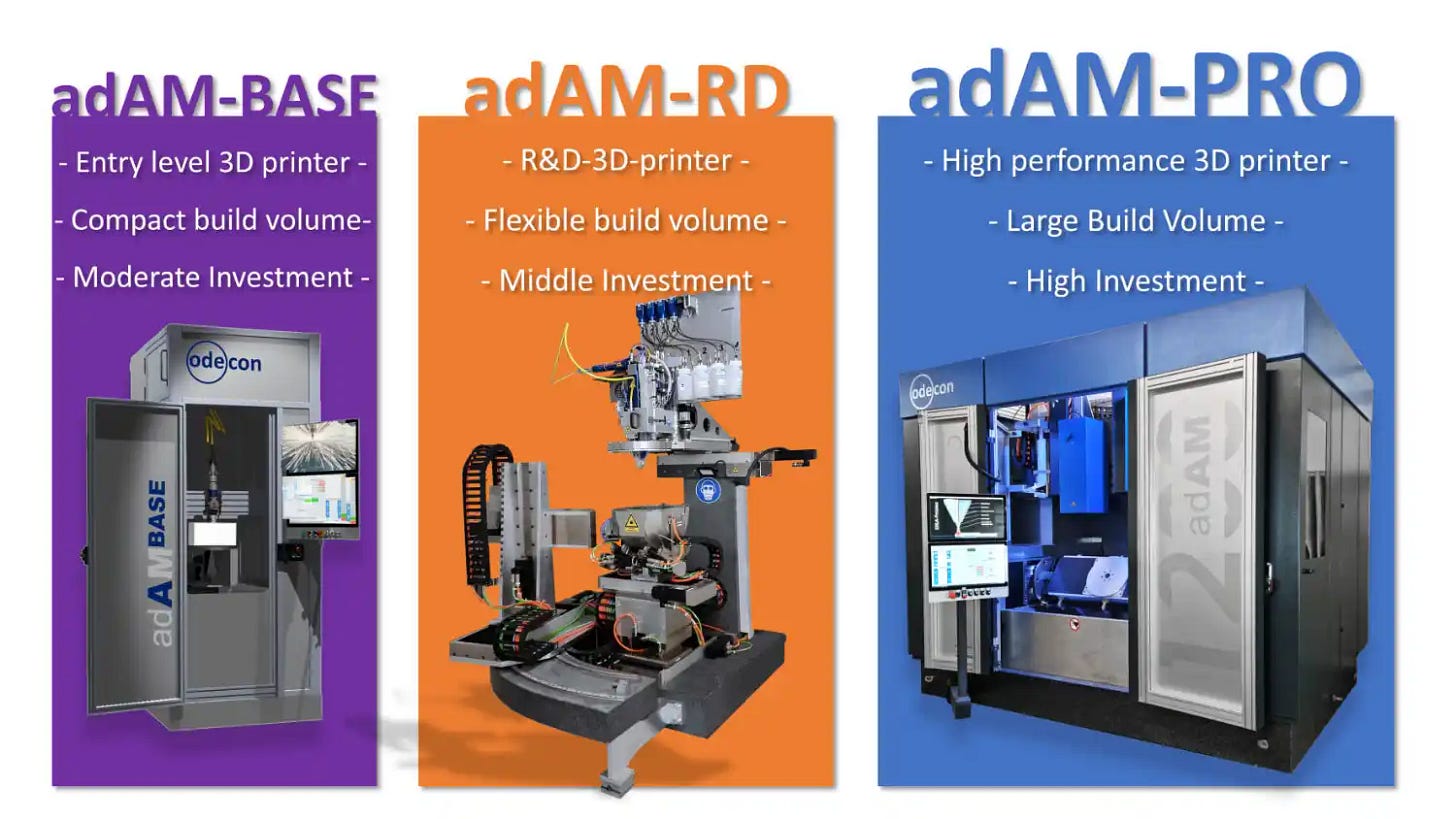

Business activities: Hardware Manufacturer

AM services:

DED / WAAM

Distribution:

adAM-BASE (entry level – 5 axis metal 3D printer for serial production inclusive post processing)

adAM-RD (metal and misc material 3D printer for research & development)

adAM-PRO (industrial highend 3D-printer for serial production inclusive post processing)

isCAM (CAD/CAM software)

Activity: World

Overview:

ODeCon engineering GmbH holds a leading position in metal 3D printing technology, particularly through the development and commercialization of the innovative adAM 3D printers. The core technology, based on the EHLA process, enables the faster, more precise, and more sustainable production and reworking of metal parts, providing a significant competitive advantage over all other metal 3D printing methods.

Legacy:

Founded in 2012 by Dipl.-Wirtsch.-Ing. Oliver Schulte, ODeCon has grown from a sole proprietorship into ODeCon engineering GmbH. The company’s focus on automation technology accounts for 50% of its revenue, with customized solutions such as fixtures and assembly machines for the electronics, plastics, and packaging industries.

In 2016, ODeCon began developing an innovative metal 3D printer concept based on EHLA technology, leading to the construction of the adAM-PRO in 2022—the world’s fastest DED 5-axis metal 3D printer with a multi-tool changer for laser-based processes.

In 2024, ODeCon is launching the adAM-RD, a unique 14-axis 3D printer for metal and plastic powders or wires, equipped with X-ray measurement for real-time material development.

By late 2024, ODeCon will introduce an entry-level metal 5-axis DED 3D printer, leveraging the versatile adAM-PRO technology for efficient serial production.

PROTOTEC

PROTOTEC GmbH & Co. KG

Askay 18, D-57439 Attendorn, Germany

Founded: 1995

www: prototec.de

e-mail: info@prototec.de

social media: LinkedIn | Facebook | Instagram

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

PBF

Distribution:

Photocentric (Printers / Resin)

Phrozen (Printers / Resin)

Henkel Loctite (Resin)

Forward AM (Resin)

Activity: World

Overview:

PROTOTEC GmbH & Co. KG is a leading industrial 3D printing service provider, specializing in additive manufacturing from prototypes to series production. With over 25 years of experience, the company offers a wide range of solutions, from engineering and design optimization to production support.

As the official distributor for Photocentric in Germany, PROTOTEC also provides advanced MSLA printers and materials, enabling customers to seamlessly integrate cutting-edge 3D printing systems into their operations. This unique combination of services and products allows businesses to fully harness the potential of additive manufacturing for practical applications.

In recognition of its innovative approach, PROTOTEC was honored twice as a "Top 100 Innovator". The company is committed to empowering clients to optimize their products and processes, emphasizing the transformative power of 3D printing technology. Through expertise, personalized consultation, and reliable support, PROTOTEC helps businesses achieve exceptional results in additive manufacturing.

Legacy:

Founded in 1995, PROTOTEC is one of the oldest 3D printing service providers in the industry. Over the years, the company grew steadily, making small yet consistent strides in an era when digitalization was still in its infancy.

In 2019, Torsten Wolschendorf assumed leadership as part of an age-related succession plan. However, the following years brought significant challenges. The Diesel-Gate scandal, the COVID-19 pandemic, geopolitical conflicts in Ukraine and Israel, and the subsequent economic crisis kept the company in "crisis mode."

Despite these hurdles, PROTOTEC continued to invest in its future. The portfolio expanded, enabling a growing number of solutions and applications. The company evolved from a prototyping specialist into a full-scale service provider for series and application-based 3D printing.

Today, PROTOTEC enjoys an excellent reputation in the market and among its customers, earning recognition as a trusted solution provider in the additive manufacturing industry.

REPLIQUE

Replique GmbH

Julius-Hatry-Straße 1, 68163 Mannheim, Germany

Founded: 2020

www: replique.io

e-mail: sales@replique.io

social media: LinkedIn

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

PBF

DED / WAAM

BinderJetting

Activity: World

Overview:

Replique is the digital manufacturing partner for demanding requirements – from custom single pieces to series production, obsolescence management, and emergency spare part supply.

With a global network of over 200 production partners, the company combines a wide range of manufacturing technologies with a strong focus on 3D printing. The goal is to select the right technology for each part to deliver the best results.

With digital inventory and the ability to produce parts on demand, companies can increase availability while reducing storage and transportation costs.

This provides a flexible and efficient solution for manufacturing needs, regardless of the industry.

Legacy:

Replique started with a bold vision within BASF’s digital transformation initiative in 2020: why not replace complex supply chains with digital files and decentralized production? With this idea, the company's founders, Henrike Wonneberger and Max Siebert, set out to create a secure platform for on-demand manufacturing. As part of Chemovator GmbH, BASF's venture builder, Replique was developed and validated in close collaboration with early customers like Miele. By 2023, Replique had become an independent company, supported by Chemovator and external investors.

What makes Replique special is the ability to combine deep material expertise with access to the entire 3D printing ecosystem. From polymer to metal parts, the company ensures the right technology and material for every application. Replique’s global production network of more than 100 trusted partners enables fast, reliable, and high-quality part manufacturing wherever it’s needed. Today, the company is proud to serve its customers across industries, including renowned names like Alstom, Danfoss, MAN, and Roche, helping them simplify supply chains and increase flexibility.

ROSSWAG ENGINEERING

Rosswag GmbH

August-Roßwag-Str. 1, 76327 Pfinztal, Germany

Founded: 1911 (2014 entered the AM business)

www: rosswag-engineering.com

e-mail: info@rosswag-engineering.de

social media: LinkedIn | YouTube

Business activities: Material Manufacturer and AM Service Provider

AM services:

PBF

Distribution:

Special LPBF Powder

Activity: World

Overview:

Rosswag Engineering, founded in 2014 as a division of the family-run Rosswag GmbH, stands out as a global pioneer in Metal Additive Manufacturing with a fully integrated, end-to-end process chain. Unlike traditional service providers, Rosswag combines i.e. in-house metal powder production, LPBF processing, heat treatment, CNC machining, and material qualification – ensuring unmatched flexibility and efficiency.

With over 50 qualified metal materials, Rosswag offers rapid customization and high-performance solutions for demanding industries like semiconductor, energy and tooling. The certified manufacturing processes and know-how from more than 100,000 produced functional components guarantee superior quality, while proprietary research and process simulation drive continuous innovation.

In 2022, Rosswag launched AddiMap, an open marketplace for process parameters and material data in Metal AM, fostering collaboration and accelerating advancements of the AM community.

Legacy:

Rosswag GmbH uniquely integrates traditional open-die forging and ring rolling (Edelstahl Rosswag) with cutting-edge Additive Manufacturing (Rosswag Engineering), setting itself apart as a one-of-a-kind metal processing company. With over 400 metal materials processed for forged components weighing up to 4.5 tons, Rosswag has built an unparalleled expertise in metal processing, material science and engineering.

The addition of Rosswag Engineering in 2014 expanded capabilities to Metal Additive Manufacturing, qualifying over 50 materials in-house and producing more than 100,000 functional components. This synergy between large-scale forging and precise 3D-Printing enables innovative hybrid manufacturing solutions. The company’s unique business model – combining extensive material expertise, traditional craftsmanship, and advanced manufacturing – leads to a unique value chain for partners and customers as well as it continues to drive innovation and industry transformation.