In 2024, the Polish economy experienced significant growth compared to other European countries. According to Eurostat data, Poland's GDP increased by 1.5% in the second quarter of 2024 compared to the first quarter, making it the best-performing country in the European Union.

An analysis of cumulative GDP growth from 2022 to the end of the first half of 2024 shows that the Polish economy grew by 5.86%, a much stronger result than in the EU-27 countries. Last year, Poland stood out in Europe with dynamic economic growth, surpassing the average rates for both the European Union and the Eurozone.

Click to download PDF version ⤓

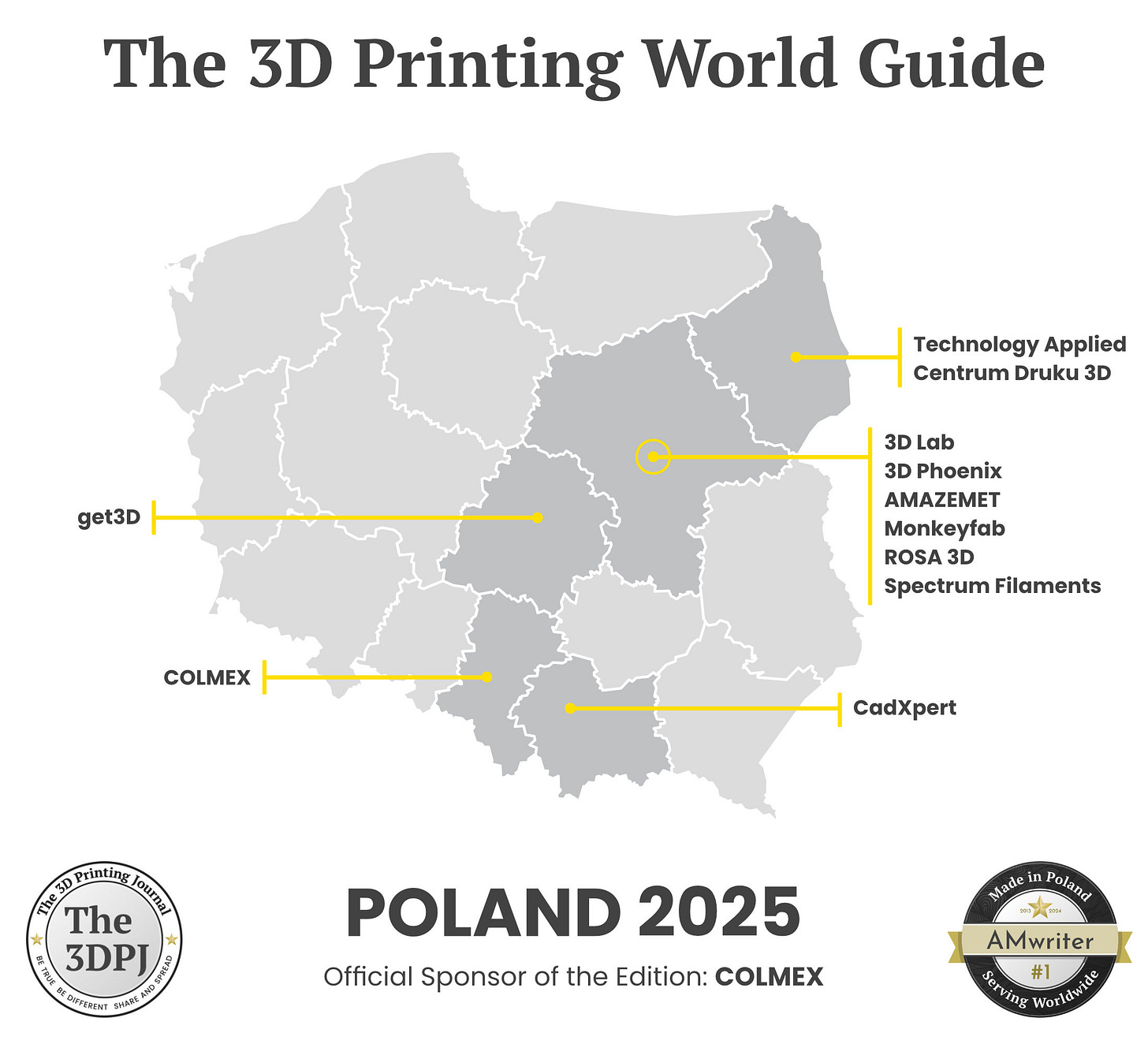

Unfortunately, this economic growth has not translated significantly to the 3D printing market. Despite being one of the largest countries in Europe, the adoption of AM technology in Poland has never been as widespread as in neighboring countries like the Czech Republic. This can be partially attributed to a certain level of technological conservatism. Poland is a substantial market for industrial machines, but these are rooted in traditional manufacturing techniques such as milling, injection molding, and casting.

Poland is by no means a technologically backward country—quite the contrary. However, manufacturing companies often choose more traditional production techniques when making decisions about adopting new technologies.

COLMEX: sponsor of the Polish Edition of The 3D Printing World Guide

The first 3D printers arrived in Poland in the late 1990s and were SLA machines from 3D Systems. The foundations of the 3D printing industry began to form in 2005 with companies like Wadim Plast, Car Technology, Solveere, e-Prototypy, Bibus Menos, Prosolutions, and 3D Lab. Of these, only the last three are still active in the area of AM. In 2014, e-Prototypy was acquired by Materialise, which used it to establish a factory in Wrocław.

Significant industry growth occurred after 2013, with the emergence of the first companies manufacturing 3D printers, filaments, as well as service and distribution firms. Among these, the most internationally successful companies include Zortrax, Sinterit, Zmorph, 3DGence, and Omni3D in the 3D printer manufacturing sector, and Spectrum Filaments, ROSA 3D, Fiberlogy, and Devil Design in the filament segment.

Currently, the most well-known Polish brands in Europe and worldwide are 3D Lab (ATO) and AMAZEMET, producers of metal powder atomizers, as well as the aforementioned filament manufacturers. Additionally, CadXpert, a leading distributor of 3D printers, and Technology Applied, the largest Polish service provider enjoy considerable recognition (though the largest service company overall is the Polish branch of the Belgian company Materialise).

Below, we present 10 companies shaping various aspects of the 3D printing market in Poland, as well as the largest portal covering the market daily. Our list includes:

2 hardware manufacturers

2 materials manufacturers

2 service providers

4 distribution companies.

COLMEX | Proud Sponsor of Polish Edition

Colmex Sp. z o.o.

Karoliniki 90/9, 44-121 Gliwice, Poland

Founded: 1988 (2016 entered the AM business)

www: colmex.pl

e-mail: colmex@colmex.pl

social media: LinkedIn

Business activities: AM Service Provider and Distributor

AM services:

PBF (metal)

BinderJetting

Distribution:

ExOne

Nikon SLM Solutions

Desktop Metal

Addiblast

Materialise (software)

Activity: Poland

Overview:

COLMEX offers comprehensive solutions in Laser Powder Bed Fusion (SLM/DMLS) technology by Nikon SLM Solutions, as well as Sand and Metal Binder Jetting systems by Desktop Metal & ExOne. The company primarily focuses on machine sales but also provides expertise, cost of ownership analysis, benchmark parts, and on-demand part production.

In addition to 3D printers, COLMEX also offers supplementary solutions such as software (Materialise) and post-processing equipment (Addiblast). COLMEX is the only company in Poland fully dedicated to metal part production via additive manufacturing. The company provides direct metal printing using two technologies – L-PBF (SLM/DMLS) by Nikon SLM Solutions and Binder Jetting by Desktop Metal. It also offers an indirect approach, printing sand cores and molds with ExOne technology for the foundry industry, enabling the casting of metal parts.

Legacy:

Back in 1988 future COLMEX CEO decided to quit his job and started own business by sending telex (not even a fax!) to an unknown German company Jaudt, manufacturing dosing systems. A business relation started (which continues to this day) and Colmex has been recommended to another companies, including ExOne. In 2016, its journey in the AM field began. Later (through a merger), COLMEX added Desktop Metal to its portfolio and, thanks to a former ExOne employee, it partnered with Nikon SLM Solutions.

Simply recommendation after recommendation….

As COLMEX claims, they are far from being revolutionary, far from the best (they sell 1-2 systems per year – best is yet to come), but they are proud of building special relationships with customers and partners that have lasted for decades. List of 3D printed applications include: pumps, automotive parts, aviation parts, tools, medical devices, oil&gas, decorative, military. All sand & metal.

Last but not least, COLMEX is also multimedalist of Polish Foundry championships in alpine skiing!

3D LAB

3D Lab Sp. z o.o.

Farbiarska 63B, 02-862 Warszawa, Poland

Founded: 2007

www: metalatomizer.com, www.3d-lab.pl

e-mail: sales@3d-lab.pl

social media: LinkedIn

Business activities: Hardware Manufacturer, AM Service Provider, Distributor

AM services:

SLA / DLP

SLS

SLM / DMP

MJP

CJP

Distribution:

ATO

3D Systems

2oneLab

Activity: World

Overview:

3D Lab are the inventors and pioneers in the use of ultrasonic technology for metal powder production with lab-size devices construction and no minimum batch size limit. The company created the ATO Suite - a modular set of powder manufacturing and processing equipment that enables metal atomization, sieving, casting, and cleaning of raw materials and atomizer components with seamless workflow.

The ATO Technology developed and patented within the company is a revolutionary method of transforming own alloys in any feedstock form into highly spherical metal powders, which are excellent for use in a wide range of AM technologies and applications. Equipment is modular, with easily interchangeable modules to change melting method or produced powder size.

Legacy:

3D Lab was founded in 2007 as a Z Corporation distributor in Poland. Since 2012, 3D Lab has served as a reseller of 3D Systems. In the following years, 3D Lab partnered with other well-known 3D printer manufacturers such as Coherent and 2OneLab. It also invested in R&D to overcome obstacles in metal 3D printing. As a result, 3D Lab came up with a solution to guarantee the freedom of atomization of metal alloys.

At Formnext 2017, 3D Lab unveiled the ATO One, its first ultrasonic atomizer prototype, designed for universities, research departments and service bureaus, but now also used by industrial users and appreciated for the stability and repeatability achieved. ATO atomizers are a revolutionary method for producing highly spherical metallic powders, used by over 80 researchers & manufacturers around the world to produce their own powders and drive innovations in AM. It is a game changer for a wide range of industries including manufacturing, aerospace, healthcare, science and education.

3D PHOENIX

3D Phoenix Sp. z o.o.

Jeziorna 1, 05-092 Łomianki, Poland

Founded: 2015

www: 3dphoenix.pl

e-mail: kontakt@3dphoenix.pl

social media: LinkedIn | Facebook | YouTube

Business activities: Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

PBF

DED / WAAM

BinderJetting

Distribution:

Markforged

Meltio

SPEE3D

Eplus3D

Acuretta

Mimaki

3DISC

Nexa3D

Activity: Poland

Overview:

3D Phoenix is a leader in additive manufacturing technology in Poland, offering advanced solutions in 3D printing with metal, composites, resins, and SLS technology. The company specializes in seamlessly implementing 3D printing technologies and devices into existing production processes, ensuring smooth integration and maximum efficiency.

By collaborating exclusively with trusted and renowned manufacturers of additive technologies, 3D Phoenix delivers top-quality equipment that meets the needs of both large industrial enterprises and smaller companies. The solutions provided by the company streamline design, prototyping, and production processes, minimize the risk of downtime, and enhance operational efficiency.

The team of experts at 3D Phoenix supports clients at every stage of implementation, offering comprehensive technical assistance and expertise to fully leverage the potential of 3D printing in industrial applications.

Legacy:

3D Phoenix was founded in 2015 out of a passion for modern technologies and has been supporting the development of Polish industry for years by promoting additive manufacturing solutions. Its priority is to deliver devices exclusively from trusted and renowned manufacturers, ensuring reliability and the highest standards of offered solutions.

The experienced team of engineers specializes in conducting technological audits and optimizing production processes, tailoring solutions to the individual needs of clients. With advanced technologies and comprehensive technical support, 3D Phoenix enables businesses to achieve higher efficiency, reduce operational costs, and realize complex projects. The uniqueness of the company lies in its passion, experience, and commitment, making 3D Phoenix a trusted partner in the process of production modernization.

AMAZEMET

AMAZEMET Sp. z o.o.

Aleja Jana Pawła II 27, 00-867 Warszawa, Poland

Founded: 2019

www: amazemet.com

e-mail: office@amazemet.com

social media: LinkedIn | Facebook | YouTube

Business activities: Hardware Manufacturer, Material Manufacturer, AM Service Provider, Distributor

AM services:

PBF

DED / WAAM

Distribution:

rePOWDER (world)

inFURNER (world)

arcMELTER (world)

Powder2Powder (world)

Aconity3D (Poland only)

Colibrium Additive (Poland only)

Indutherm (Poland only)

Activity: World

Overview:

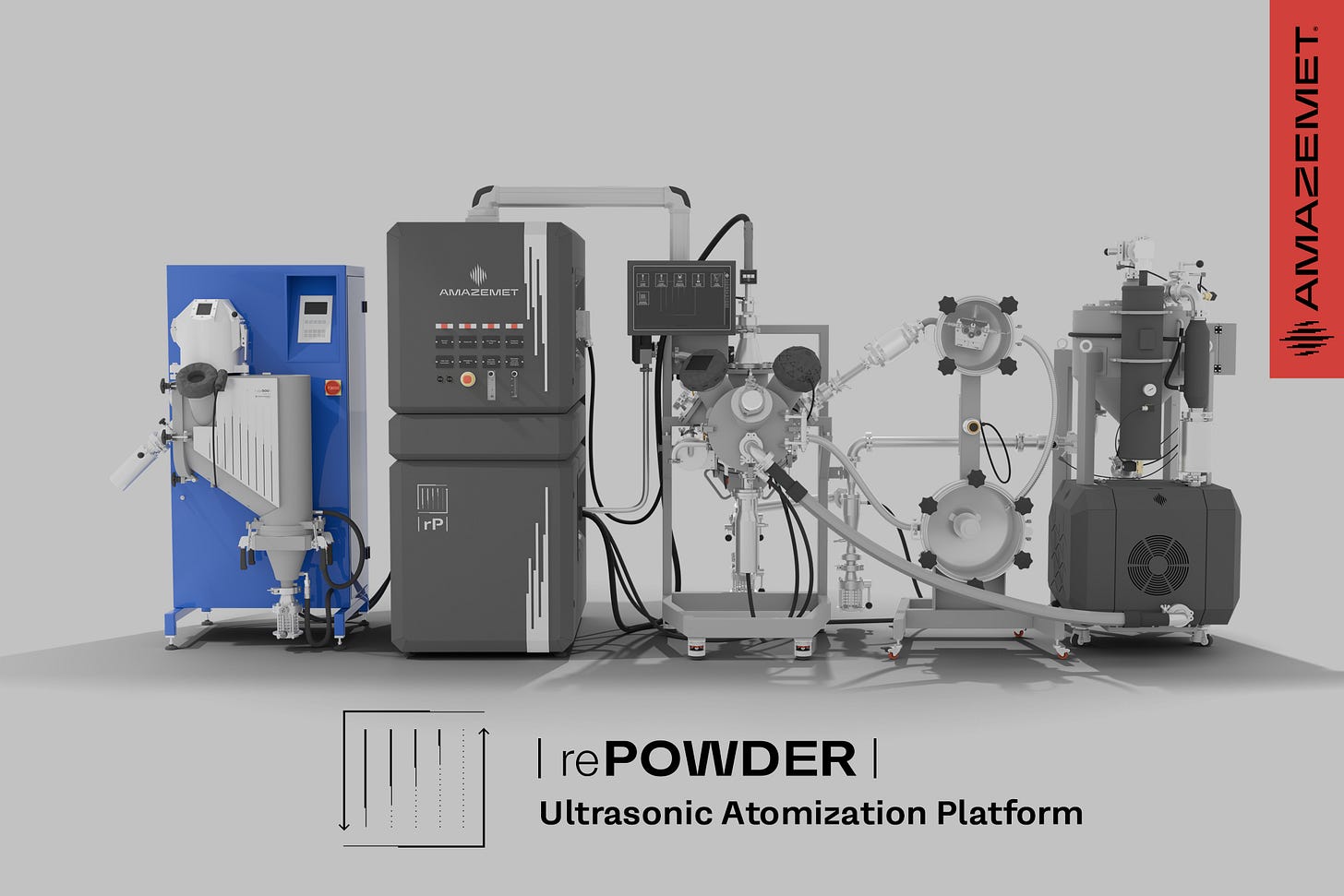

AMAZEMET, a 2019 spin-off from Warsaw University of Technology, specializes in providing and developing advanced ultrasonic atomization devices for tailored powder manufacturing and compact high-vacuum furnaces for post-processing and heat-treatment applications. Laboratory-scale solutions like rePOWDER and inFURNER support leading researchers worldwide in Additive Manufacturing and beyond.

AMAZEMET’s newest solution, Powder2Powder, enables ultrasonic atomization from any powder feedstock. Building on its expertise in materials science, AMAZEMET has expanded its operations to include the production of custom metal powders tailored to specific requirements. Rooted in academia, AMAZEMET actively collaborates on research projects (9 projects granted) to develop innovative materials for AM, maintaining strong ties with scientists and academic institutions around the globe.

AMAZEMET also partners with industry leaders such as Colibrium Additive, Aconity, and Indutherm. Additionally, AMAZEMET offers production and engineering services such as welding, CNC machining, metal 3D printing, for demanding small and medium production runs.

Legacy:

AMAZEMET’s technology is a game-changer for material research and metal additive manufacturing, offering a revived approach to ultrasonic atomization that transforms powder production and material development. Although ultrasonic atomization was first introduced in the 1960s, it was overshadowed by gas atomization and low demand for ultra-spherical particles. Currently, with the growing need for small-scale powder production, AMAZEMET has modernized and refined this technology.

The catalyst was a Ph.D. student’s search for an affordable method to produce a batch of bulk metallic glass powder. By rediscovering ultrasonic atomization, AMAZEMET’s founder, Łukasz Żrodowski, developed an in-house solution, rePOWDER, backed by 12 patented solutions.

Now, AMAZEMET’s ultrasonic metal atomizer broadens scientific possibilities while driving progress and sustainability in additive manufacturing and beyond. The company integrates scientific expertise with industrial needs, aiding researchers in over 70 locations worldwide, including NASA, EMPA, Georgia Tech, Northwestern University, and Oak Ridge National Lab.

CADXPERT

CadXpert P. Gurga M. Dukat Spółka Komandytowa

Ciepłownicza 23, 31-574 Kraków, Poland

Founded: 2013

www: cadxpert.pl

e-mail: info@druk3d.cx

social media: LinkedIn | Facebook | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

PolyJet

SLS & SAF

DMLS

Distribution:

Stratasys

Formlabs

UltiMaker

BLT

MakerBot

Activity: Europe

Overview:

CADXPERT is distributor of equipment from such renowned brands as Stratasys, Formlabs, UltiMaker and BLT. The company gained recognition from producers as Platinum Partners of Stratasys and base their sales on years of experience in the market, always emphasizing ROI.

CADXPERT also provides 3D printing services in SLA/DLP, SLS, FDM, SAF, PolyJet and DMLS technologies with quick turnaround times and professional counselling. The company has its own design department, whose activity is to provide cutting-edge solutions and prototypes for a wide range of industries.

The aim of CADXPERT is to help the industry simplify and accelerate AM methods, promote 3D printing in Poland and focus on solutions that improve the daily functioning of maintenance departments, R&D and production lines in companies.

Legacy:

CADXPERTS are pioneers on the Polish market when it comes to distribution of the above brands, and in terms of services, it can boast the widest range of technologies in which it works.

Most important achievements:

2021-2024 – Platinum Partner Stratasys

2024 – partner of Bright Laser Technologies (BLT) for Central Europe and the Baltics

2020 – opening of new offices with a large machine park in Krakow

2019 – launch of AM's own services department

2013 – start date of distribution of MakerBot equipment.

GET3D

get3D Sp. z o.o.

Wigury 21, 90-319 Łódź, Poland

Founded: 2014

www: get3d.pl

e-mail: biuro@get3d.pl

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: AM Service Provider and Distributor

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

BinderJetting

Distribution:

UltiMaker

Bambu Lab

Raise3D

Desktop Metal

miniFactory

Activity: Poland

Overview:

get3D have been in the polish AM industry since the very beginning. The company specialise in providing AM technology solutions, implementations and distribution of production equipment and materials for small, medium and large companies as well as for private individuals. get3D also offers contract 3D printing services. As a long-time partner of many world-wide known 3D manufacturers the company is able to offer the best solution for your company needs.

Legacy:

For more than 10 years, we have been supplying 3D printers and consumables and, above all, solutions to customers who most often stay with us for years. Our technical background and very wide product range, as well as practical knowledge of various technologies and their applications, allow us to offer solutions dedicated to individual, often very specific, customer needs. Our own well-equipped 3D printing facility and access to a worldwide stock of diverse materials gives us the ability to produce both test prints and production runs.

MONKEYFAB

Monkeyfab s.c.

Szachowa 1, 04-894 Warszawa, Poland

Founded: 2012

www: monkeyfab.com

e-mail: studio@monkeyfab.com

social media: Facebook | Instagram | YouTube

Business activities: Hardware Manufacturer and AM Service Provider

AM services:

FDM / FFF

SLA / DLP

Activity: Europe

Overview:

Monkeyfab delivers innovative products based on 3D printing, tailored to a wide range of industries. Our clients include museums, artists, architects, advertising agencies, and design firms. With expertise in 3D scanning, CAD design, mesh modeling, and organic sculpting, the comapny brings a unique character to every project.

By blending cutting-edge technology with traditional artistic techniques, Monkeyfab ensures exceptional results. From concept and visualization to technical design, material selection, and integration with existing infrastructure, the company provides comprehensive support at every stage. Monkeyfab’ services include transport, installation, maintenance, and warranty, offering complete, ready-to-use solutions designed to exceed expectations.

Legacy:

Monkeyfab was founded in 2012 by Piotr and Paweł Twardo brothers on the wave of the 3D printing revolution. They have been designing and manufacturing various types of 3D printers: the workhorse Prime 3D, finetuned and subtle Spire and the massive KILO. Their machines gained popularity and many awards like CD3D Printer of the year or Kielce Fair Best Product; they were offered by ABCData – one of polish largest retailers. From 2016 Monkeyfab is proudly providing custom services based on 3D printing, combinig world of technology and art.

ROSA 3D

ROSA PLAST Sp. z o.o.

Hipolitowska 102B, 05-074 Hipolitów, Poland

Founded: 1979 (2018 entered the AM business)

www: rosa3d.pl

e-mail: 3d@rosaplast.pl

social media: Facebook | Instagram | TikTok | YouTube

Business activities: Material Manufacturer and Distributor

Distribution:

ROSA 3D Filaments

Prusa Research

Drywise

Activity: Europe

Overview:

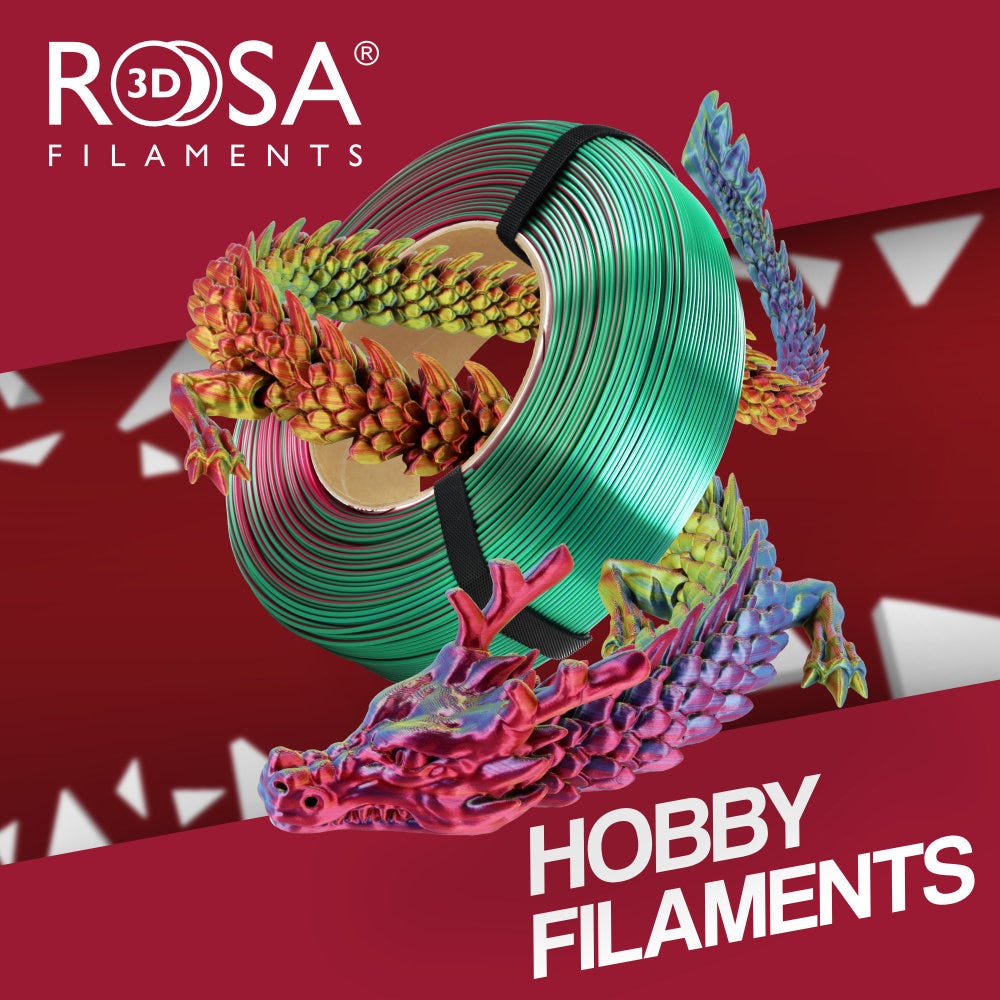

ROSA 3D Filaments produces filaments – and takes it seriously!

The company offers a wide selection of high-quality hobby filaments, all locally produced in Europe. These include rainbow filaments, 2- and 3-color magic series, glitter, UV-glow, pastel series, and many other innovative products available in a broad range of colors. ROSA 3D ensures the highest environmental standards (ISO 14001) and utilizes renewable energy sources in its production processes.

The standout feature of the company’s offering, however, is its high-quality technical materials. ROSA 3D provides a diverse range of technical filaments, all manufactured in compliance with the ISO 9001 standard. The portfolio includes exceptional materials such as PA12+15CF, PC-PBT, ASA+Kevlar, TPU, and PET-G "Glow in the Dark," among others, with the range constantly expanding. ROSA 3D introduces new products every month to meet the evolving needs of the market.

Legacy:

ROSA 3D is a European company with a long-standing history of production in Poland, operating continuously since 1979 and spanning over 45 years across two generations. Originally specializing in hoses and extruded profiles made from polyolefins and PVC, ROSA 3D expanded into filament production in 2018. This rich experience is reflected in the company’s portfolio, which includes a wide selection of materials for both hobby and technical applications. Currently, ROSA 3D offers over 450 SKUs, and this number continues to grow.

For ROSA 3D, ecology is more than just a statement. The company not only produces its products using renewable energy sources but also offers a diverse range of refill products. These include not only PLA but also PET-G, ASA, PCTG, and even some carbon fiber-reinforced materials. ROSA 3D’s refill system is designed to enable the reuse of masterspools, allowing users to securely fasten and dismantle refills after using only part of the filament, making it easy to switch colors while ensuring safe handling.

SPECTRUM FILAMENTS

Spectrum Group Sp. z o.o.

Parkowa 85, 05-806 Pecice, Poland

Founded: 2015

www: spectrumfilaments.com

e-mail: office@spectrumfilaments.com

social media: LinkedIn | Facebook | Instagram | TikTok | YouTube

Business activities: Material Manufacturer and AM Service Provider

AM services:

FDM / FFF

Distribution:

Spectrum Filaments

The Filament

Prografen

Activity: World

Overview:

Spectrum is a leading European manufacturer of 3D printing filaments, specializing in innovative solutions for FDM/FFF technology. With over 80 diverse filament types in itsr portfolio and a production capacity of 1.5 million kilograms annually. In addition to extensive product range, Spectrum offers comprehensive OEM services, including private labeling and customized filament solutions tailored to specific customer needs.

Known for our commitment to quality, sustainability and customer satisfaction, all Spectrum products are manufactured in its facility in Europe under stringent standards. From standard filaments to advanced industrial materials, Spectrum supports individuals and businesses in realizing even the most complex projects while fostering strong, long-term partnerships.

Legacy:

Founded in 2015 with a passion for innovation, Spectrum has grown into one of the most trusted names in the 3D printing filament industry. Over the years, the company has developed groundbreaking products such as ASA 275, GreenyHT, PC 275, ASA-X CF10, Antibacterial PLA and many more – unique materials available exclusively at Spectrum.

These innovations demonstrate Spectrum’ commitment to advancing material science and addressing the ever-changing needs of our customers. The company’s commitment to quality and innovation has been recognized with the prestigious award for the best Polish filament manufacturer. From eco-friendly practices and pioneering new technologies to offering ReFill solutions compatible with Bambu Lab, Spectrum delivers exceptional quality, shaping the future of 3D printing and maintaining a legacy of excellence.

TECHNOLOGY APPLIED

Technology Applied Sp. z o.o.

Transportowa 2D/45, 15-399 Białystok, Poland

Founded: 2015

www: ta.parts

e-mail: info@ta.parts

social media: LinkedIn

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

SLS

MJF

Activity: Europe

Overview:

Technology Applied is an advanced 3D printing company specializing in contract producing of plastic parts. It provides e.g. functional parts for machines, devices and production lines, as well as small and medium series of products. The company's expertise includes a wide range of printing technologies: SLS, MJF, DLP, SLA and FDM, as well as post-processing methods: polishing, vapor smoothing, coloring, threaded inserts, bonding.

The company's experience in the industry and its own industrial machinery means that the offered prints are characterized by high accuracy, repeatability and durability. The company has ISO 9001:2015 certified processes, confirming a commitment to the highest standards.

Technology Applied is a pioneer in its sector – it is the only company in this part of Europe with a professional vapor smoothing system which allows it to deliver products of a quality that surpasses anything previously available on the market.

Legacy:

Technology Applied began its operations in 2015, offering 3D printing using the SLS method. The company's service offerings have expanded significantly over time with the introduction of additional machines and new production methods. To meet growing customer demands, the company has invested in specialized, certified materials and advanced post-processing techniques.

The implementation of DyeMansion's post-processing systems has improved production processes and resulted in a higher quality product, enhancing customer satisfaction.

Technology Applied specializes in serving industrial clients and has successfully completed a wide range of projects, from the production of spare parts for e.g., vintage textile machinery to the serial production of final products.

Significant projects have been undertaken in the medical sector, including the production of custom-sized orthotic braces, and in the military industry, where the company has manufactured 50,000 flight stabilizers for drones.

CENTRUM DRUKU 3D (3D Printing Center)

CD3D

Wiejska 42/3, 15-509 Sobolewo, Poland

Founded: 2013

www: centrumdruku3d.pl

e-mail: redakcja@centrumdruku3d.pl

social media: LinkedIn

Overview:

Centrum Druku 3D (en. 3D Printing Center) is the longest-running portal dedicated to 3D printing in Poland. Over the years, the portal has played a pivotal role in establishing the majority of 3D printing companies in Poland and has supported countless manufacturing and service companies, schools, and universities in adopting additive manufacturing technologies.

Centrum Druku 3D was founded by Pawel Slusarczyk at a time when the 3D printing industry in Poland was virtually non-existent, and awareness of additive manufacturing technologies was minimal. The portal changed that landscape. Many of the key companies in Poland and abroad made their debuts on Centrum Druku 3D's platform.

The portal provided information about 3D printing, offered training on the technology, and facilitated its implementation in companies, research institutions, schools, and universities. Centrum Druku 3D organized trade shows, conferences, and events, including the first global competition to recognize the best companies and products in the 3D printing industry.