Spain is the fourth-largest economy in the European Union, and it clearly plays a significant role in the European economic landscape. The country is characterized by a diverse economic structure, with a strong services sector, tourism, and a growing high-tech industry.

The 3D printing sector is still relatively young and doesn’t yet play a major role in Spain’s overall economy, but it holds a solid position and recognition in the global AM industry. Several large companies originate from Spain, but the most significant impact came from the R&D division of American company HP!

Click to download PDF version ⤓

Similar to most European countries, the 3D printing industry in Spain began to take shape on a larger scale after 2010. One of the most recognizable companies worldwide is BCN3D, a Catalan company based in Barcelona, which manufactures FFF 3D printers. BCN3D developed the IDEX system, which uses two independent print heads. Importantly, the company released the designs of its early models (the Sigma line) under an open-source license, which helped spread this innovation globally.

Another key player on the Spanish 3D printing scene is Recreus, known for developing flexible 3D printing filaments, such as the globally recognized FilaFlex. Sicnova, founded in 2007 and based in Jaén, specializes in providing advanced 3D printing solutions for the medical and industrial sectors. It’s also worth mentioning Print&Go, which combines 3D printing with modern IT technologies. Print&Go offers a cloud-based platform for managing 3D printing projects, allowing users to remotely monitor and control printing processes.

However, the real revolution in the 3D printing sector came with the development of MJF (Multi Jet Fusion) technology, created by HP at its R&D center in Barcelona. MJF technology was a breakthrough in 3D printing, offering the first real alternative to the SLS method. HP chose Barcelona as the headquarters for its R&D division due to the strong presence of innovative companies and research institutions in the region. Thus, Barcelona has become not only a key hub for Spain’s 3D printing sector but also a global center of innovation in this field.

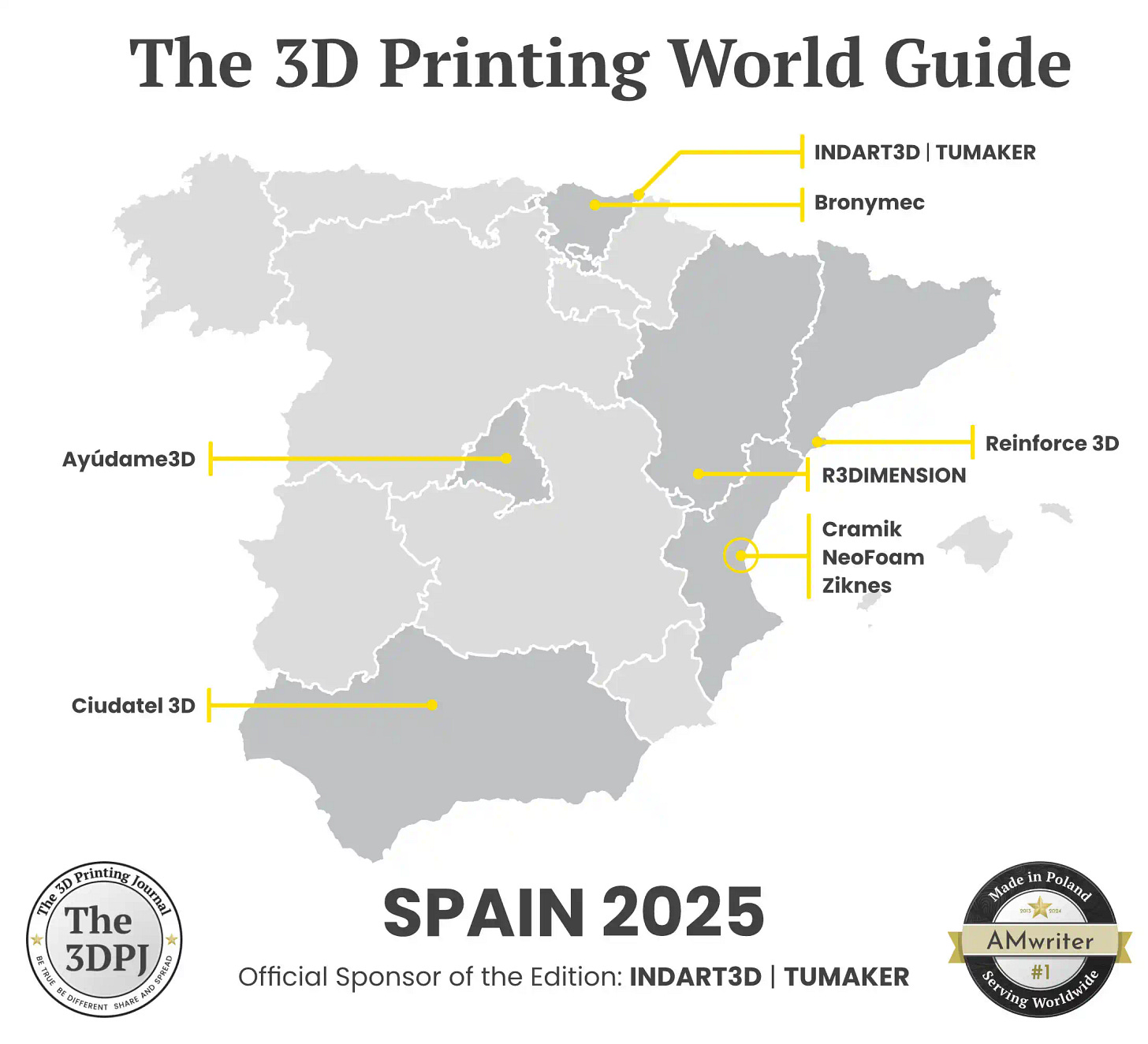

INDART3D: sponsor of the Spanish Edition of The 3D Printing World Guide

As for the state of the Spanish economy in 2022-2024, the situation is complex. In 2022, Spain recorded GDP growth of about 5.5%, driven by recovery from the COVID-19 pandemic and support from EU funds. However, in subsequent years, the growth rate slowed to around 2.4% in 2023 and an estimated 1.9% in 2024, according to the International Monetary Fund (IMF).

The main challenges remain high inflation, which averaged 4.1% in 2023, and rising energy costs, impacting business conditions and consumer purchasing power. Despite this, Spain maintains stable economic foundations, and the tourism sector, a cornerstone of the economy, is returning to pre-pandemic levels. Additionally, investments in green energy and digitalization, financed partly by the EU Recovery Fund, represent an opportunity for long-term growth.

In summary, the 3D printing sector in Spain is developing dynamically, aligning with global trends in innovation. Spanish companies are playing an increasingly significant role on the international stage, and national research centers, like the one in Barcelona, are contributing to technological progress. Despite economic challenges like slowing GDP growth or inflation, Spain remains an important player in the European economy, and the 3D printing sector is gaining a more prominent position on the global AM map.

INDART3D | Proud Sponsor of Spanish Edition

Indart3D S.Coop.

Gabiria 88, 20305, Irun, Spain

Founded: 2020

www: indart3d.com

e-mail: info@indart3d.com

social media: LinkedIn | Instagram

Business activities: Hardware Manufacturer

AM services:

FDM / FFF

Distribution:

Tumaker

Activity: World

Overview:

Indart3D, under its Tumaker brand, has revolutionized 3D printing by developing modular printers that combine filament and pellet extrusion in a single system. As pioneers in introducing pellet technology in desktop-format printers, they have enabled the use of materials unavailable in filament form, offering new opportunities for sectors such as research, industrial design, and manufacturing.

Their printers stand out not only for their versatility but also for their ability to support the research and development of new materials, making them essential tools for universities, research centers, and companies. Additionally, thanks to their advanced technology, Indart3D has established a distribution network across multiple countries, positioning itself as a key international player in the industry.

Legacy:

In 2020, the company underwent a strategic shift that reinforced its focus on pellet technology and sustainability, establishing itself as a leader in additive manufacturing through pellet extrusion in desktop 3D printers. However, Tumaker 3D printers have been manufactured since 2013, and in 2015, the company became one of the first to embrace pellet technology.

This extensive experience enables Indart3D to provide expert guidance to its customers, offering advanced solutions that combine pellet and filament extrusion in a single machine. Furthermore, as a manufacturer, Indart3D customizes its printers to meet specific client needs, even developing machines with up to four extruders. This innovative and adaptable approach has solidified its reputation as a benchmark in sustainable 3D printing, capable of addressing the industry’s most demanding challenges.

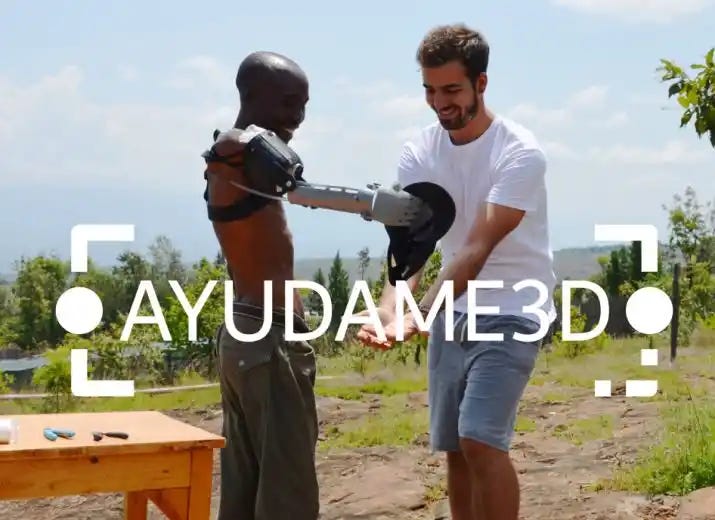

AYÚDAME3D

Ayúdame3D

Calle de Soria 9, planta 4, 28005, Madrid

Founded: 2018

www: ayudame3d.org

e-mail: info@ayudame3d.org

social media: LinkedIn | Facebook | Instagram | TikTok

Business activities: Non-profit organisation

AM services:

FDM / FFF

Activity: World

Overview:

Ayúdame3D manufactures prostheses for people who are amputees or who have been born without an arm. The organisation has delivered hundreds of them in Spain, Mexico, Colombia, Kenya, Thailand, and more than 50 other countries free of charge for people with disabilities who could never access this type of aid.

Giving them this opportunity would improve their quality of life, increase their employability and, in the case of children in many countries, would allow them to go to school.

Ayúdame3D is one of the top trophies and merchandising brands in Spain, using recycled plastic and the same 3D printers that change lives. The organisation also creates team-building events worldwide with companies where employees build prosthetic arms during a competition event.

Legacy:

Ayúdame3D created the first 3D printed arm for people with no elbow; after that, they became a full team of biomedical engineers creating devices that never existed before, just to help.

BRONYMEC

Bronymec, S.A.

Pol. Ind. Arriaga, Ferreria kalea 4, Elgoibar - Gipuzkoa, Spain

Founded: 1995

www: bronymec.com

e-mail: info@bronymec.com

social media: LinkedIn

Business activities: AM Service Provider

AM services:

MJF

Distribution:

HP PA12

HP PA12FR

TPU

Activity: World

Overview:

With over 30 years of expertise in polymer engineering, Bronymec specializes in designing and manufacturing high-performance polymer components. Bronymec's advanced manufacturing capabilities include CNC machining and additive manufacturing, with a dedicated focus on MJF technology.

Bronymec goes beyond simple 3D printing by applying Design for Additive Manufacturing (DfAM) principles to enhance functionality, cost efficiency, and sustainability. Through its Luma Service, Bronymec helps optimize product designs, delivering tangible improvements in performance and reducing environmental impact.

As the first European company to collaborate with HP and Evonik on the flame-retardant PA12FR, Bronymec is pioneering safer, high-performance solutions for industries where fire resistance is critical, such as transportation and electronics.

Legacy:

Bronymec was founded over three decades ago as a specialist in technical plastics, evolving into a reference in polymer machining and advanced manufacturing. Bronymec's commitment to continuous innovation has led the company to embrace cutting-edge materials and technologies, making it a trusted partner for demanding industrial sectors.

Bronymec's journey into additive manufacturing was a natural evolution, leveraging its deep knowledge of polymers to maximize the potential of 3D printing. The launch of the Luma Service marked a milestone, allowing companies to rethink their designs with a truly additive approach.

By becoming Europe’s first HP beta tester for PA12FR, Bronymec has strengthened its role at the forefront of the AM industry, offering certified, fire-resistant solutions that meet the most stringent safety and performance standards.

CIUDATEL 3D

Ciudatel 3D

Astrónoma Cecilia Payne, Edificio Aldebarán, 2º 2.8 – 14014 Córdoba, Spain

Founded: 2013

www: ciudatel.es

e-mail: ciudatel@ciudatel.es

social media: LinkedIn | Facebook | Instagram

Business activities: AM Service Provider and Distributor

AM Services:

FDM / FFF

SLA / DLP

SLS

DED / WAAM

Distribution:

UltiMaker

Formlabs

Shining 3D

Smart Materials 3D

Bambu Lab

Activity: Spain

Overview:

Ciudatel 3D offers on-demand 3D printing services for all types of sectors, both industrial and consumer. It has several manufacturing technologies such as FDM, SLS, SLA or LMD. They are also distributors of the big brands in the sector such as UltiMaker, Formlabs, Bambulab, Smart Materials 3D or Shining 3D.

It offers complete service and 100% personalized attention, from the sketch or prototype, through the design, development and implementation of your project. They carefully study the material and technology that best suits it.

The company also carries out reverse engineering and digitization work on pieces of a diverse nature, both for reproduction and for conservation or digital use.

Legacy:

Ciudatel 3D emerged in 2013 from the passion for technology and design and the union of a machinery technician and an engineer.

Throughout these years they have positioned themselves as a company specialized in additive manufacturing in the area thanks to such specific applications as archaeology, imagery, crafts and industry.

They have several success stories such as the development of spare parts for the Smart Roadster's hood opening mechanism or the 3D printing of molds for the manufacture of hydraulic tiles, as well as prototypes in the ceramics or packaging industry.

CRAMIK

CRAMIK ADDITIVE SOLUTIONS, S.L.

Calle Velluters, Nave 1.8, Parque Empresarial Tactica, 46988, Paterna, Valencia, Spain

Founded: 2018

www: cramik.eu

e-mail: info@cramik.eu

social media: LinkedIn

Business activities: Material Manufacturer

AM services:

FDM / FFF

Activity: World

Overview:

CRAMIC's flagship technology (called "Cramio," a patented polymeric hyperbinder WO2017/191340A1) sets a new standard for ceramic versatility. This revolutionary material supports diverse manufacturing processes—such as fused deposition modelling (FDM), liquid deposition modelling (LDM), ceramic injection moulding (IM), and advanced coatings—empowering industries with scalable, high-performance ceramic solutions.

From its 550 m² facility in the Táctica Business Park, Valencia—a hub for technological start-ups and research institutes—CRAMIC enables advancements in ceramic technology from proof-of-concept to semi-industrial production. Embedded in this vibrant ecosystem since 2023, the company benefits from invaluable networking opportunities, access to specialized talent, and the dynamic collaboration necessary to fuel its growth.

Legacy:

Established in 2016-2017 by four visionary researchers from the University of Castilla-La Mancha, CRAMIC's mission is to transform ceramics into a cornerstone of Industry 4.0.

CRAMIC's team combines over 20 years of expertise in chemistry, material science, and AM, enabling the company to develop advanced ceramics for the most demanding environments. Comprising 7 members with expertise in material engineering and energy, CRAMIC bridges the gap between groundbreaking research and industrial applications, driving innovation in technical applications.

These validations, combined with CRAMIC's affordability, speed, and flexibility, position the company's solution as the preferred choice for advanced ceramics manufacturing, making it a transformative option for industries seeking cost and time efficiency.

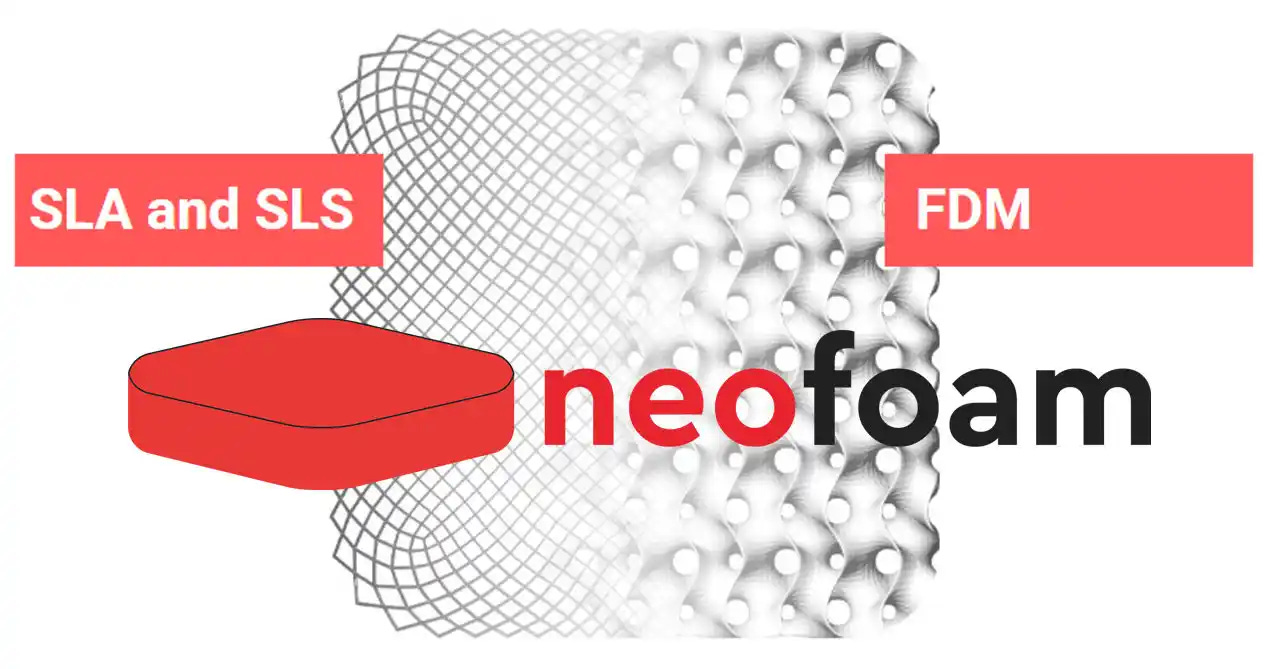

NEOFOAM

NeoFoam SL

Plaza de Vannes, 146007, Valencia, Spain

Founded: 2024

www: neofoam.eu

e-mail: info@neofoam.eu

social media: LinkedIn

Business activities: AM Service Provider

AM services:

FDM / FFF

SLA / DLP

Activity: World

Overview:

NeoFoam is pioneering Digital Foam Manufacturing. NeoFoam specializes in creating custom, cost-effective, and fully recyclable foam solutions using advanced 3D printing technologies. The company's core innovation, Variable Density Technology, allows precise control over foam properties within a single product, enabling unmatched comfort, protection, and performance.

NeoFoam offers tailored manufacturing services for insoles, seating systems, cushions, and other flexible or rigid applications across industries such as medical, automotive, and sports. The company's capabilities include rapid prototyping, scalable production, and seamless integration of advanced materials like ColorFabb Varioshore and BASF Ultrafuse TPU.

With a focus on sustainability, NeoFoam eliminates traditional molds, reduces waste, and enables local production. Whether it’s personalized orthopedic solutions or industrial-grade components, the company delivers innovative products that are durable, lightweight, and recyclable.

Choose NeoFoam to unlock new possibilities in digital foam manufacturing and redefine what’s achievable with modern materials and technologies.

Legacy:

NeoFoam started with a simple goal: to challenge the limits of traditional foam manufacturing. From day one, the company focused on creating cost-effective, eco-friendly, customizable, and fully recyclable foam solutions using 3D printing.

What truly sets NeoFoam apart is its Variable Density technology for FDM/FFF printing, which allows fine-tuning of foam properties within a single product. This breakthrough opened up new low-cost, but effective possibilities for industries like healthcare, sports, and automotive—whether it’s creating orthopedic insoles, lightweight wheelchair cushions, or ergonomic seating systems.

Along the way, NeoFoam has worked with amazing materials like ColorFabb’s Varioshore and BASF’s Ultrafuse TPU, and collaborated with leaders like Carbon, Desktop Metal, and Inkbit. The company’s focus has always been on innovation, practicality, and making digital foam a cost-effective reality for everyone.

R3DIMENSION

R3DIMENSION 3D PRINTERS, SL

Avenida Sagunto 116, nave 6, Edificio CEEI Aragón, Spain

Founded: 2022

www: r3dimension.com

e-mail: info@r3dimension.com

social media: LinkedIn

Business activities: Hardware Manufacturer

AM services:

FDM / FFF

Activity: World

Overview:

R3DIMENSION is a large format spanish FDM 3D printers manufacturer. The entire process is carried out at its facilities, from the design and development phases to the assembly and marketing of the printers.

Through the development of its own technology, it is able to offer its customers a comprehensive service in terms of additive manufacturing, ranging from feasibility studies for the integration of 3D technology, through the marketing of its printers, to providing support services in the use and operation of its machinery.

Identity model is the first FDM 3D printer developed and marketed by R3DIMENSION, professional large format 3D printer that can print on a large scale products with high quality finishes; its unique features such as the Static Printing Platform and the IDEX Printing System allow it to be the most productive on the market thanks to the possibility of simultaneous printing.

Legacy:

R3DIMENSION has managed to differentiate itself from the competition thanks to the unique features of its 3D printers, the most notable of which are:

Printing volume: 1.120 x 720 x 620 mm

Deposition rate up to 760 gr/h

IDEX printing system (double independent extrusion). Allows to double productivity by being able to print on several models: copy, mirror, multi-material

Static printing platform throughout the entire printing process, improving the quality and speed of production

Filament (material) loading capacity of up to 20 kg

Full front access, optimising space for maximum usability

Ergonomic working height, with a 95 cm platform and a 7’ touchscreen display

Power supply system, micro-cut and surge protection.

Variety of materials available: ABS, ASA, FLEX, HIPS, PETG, PLA, PCCF, PACF.

REINFORCE 3D

Reinforce 3D

C/ Lligallo de Lorente, 3., 43870 Amposta, Tarragona, Spain

Founded: 2022

www: reinforce3d.com

e-mail: reinforce3d@gmail.com

social media: LinkedIn | YouTube

Business activities: Hardware Manufacturer

Activity: World

Overview:

Reinforce 3D specializes in the Continuous Fiber Injection Process (CFIP), a groundbreaking solution designed to enhance the mechanical properties of 3D-printed parts or with other manufacturing processes. This proprietary technology reinforces components with continuous fibers such as carbon fibers, significantly improving their strength, durability, lightweight and performance for demanding industrial applications.

Reinforce 3D's patented CFIP solution offers unique advantages, including increased design flexibility, reduced overall weight, superior load-bearing capacity, and a streamlined process tailored to meet industry-specific needs. Trusted by sectors like aerospace, automotive, sporting goods, and manufacturing, the company ensures high-quality, reliable results.

Reinforce 3D is committed to redefining the possibilities of 3D-printed components through its innovative CFIP technology, providing unparalleled performance and efficiency.

Legacy:

CFIP is the first technology based on reinforcing the 3D printed part after its manufacturing, rather than during it. This breakthrough concept unlocks new capabilities unimaginable before, including the ability to place fibers in all directions following complex trajectories, even though printing layers.

CFIP can reinforce parts made by any existing 3D printing technology and material, including rigid and flexible polymers such as PA12, PEEK or TPU, metals like aluminium or titanium or also ceramic materials. It also enables the integral joining of different parts providing fiber continuity from end to end, enabling efficient manufacturing of large-scale, multi-material structures.

From collaborating with leaders in aerospace and automotive to tackling high-performance materials challenges, CFIP has proven its versatility and transformative potential. Whether creating lightweight components for advanced equipment or durable parts for industrial use, each project showcases its power.

Reinforce 3D is not just improving 3D printing, but redefining it.

ZIKNES

Ziknes

Calle manel tomas 12Bm, 46110 Godella, Valencia, Spain

Founded: 2021

www: ziknes.com | laminar3d.com

e-mail: contact@ziknes.com

social media: LinkedIn (Ziknes) | LinkdIn (Laminar 3D)

Business activities: Hardware Manufacturer and Software Developer

Activity: World

Overview:

Ziknes is a leading company in Large Format Additive Manufacturing (LFAM), providing fully integrated 3D printing solutions for industrial-scale production. Its portfolio includes:

Z.Pellet: high-performance robotic arm-based 3D printer designed for large-format manufacturing.

Z.Kompact: compact, mobile robotic printer ideal for research centers, universities, and industrial applications with space constraints.

Z.Conversion: conversion package that transforms existing industrial robots into high-efficiency 3D printing systems.

Ziknes technology supports a wide range of thermoplastics, including composites and custom-engineered recycled materials, enabling high-performance and sustainable manufacturing.

At the core of its ecosystem is Laminar, a proprietary software suite that integrates slicing and process control, ensuring precision, automation, and seamless integration with robotic 3D printing. This combination provides an end-to-end solution for prototyping, mold production, and final part manufacturing.

Beyond technology, Ziknes is committed to helping companies transition to robotic 3D printing by providing training, expertise, and tailored solutions to seamlessly integrate LFAM into their existing production workflows.

For engineers, by engineers.

Legacy:

Founded in Spain, Ziknes was created with a global vision: to revolutionize large-scale 3D printing through advanced robotics, hardware, and software. With a multidisciplinary team of engineers and designers, the company seamlessly integrates automation and additive manufacturing, driving innovation in industrial production.

In 2024, Ziknes secured a €1 million investment round to fuel its international expansion in 2025, with a strong focus on Europe, the U.S., and Asia. This funding enables the company to scale its global reseller network, establish strategic partnerships, and accelerate the adoption of LFAM across multiple industries, reinforcing its position as a leader in robotic additive manufacturing.