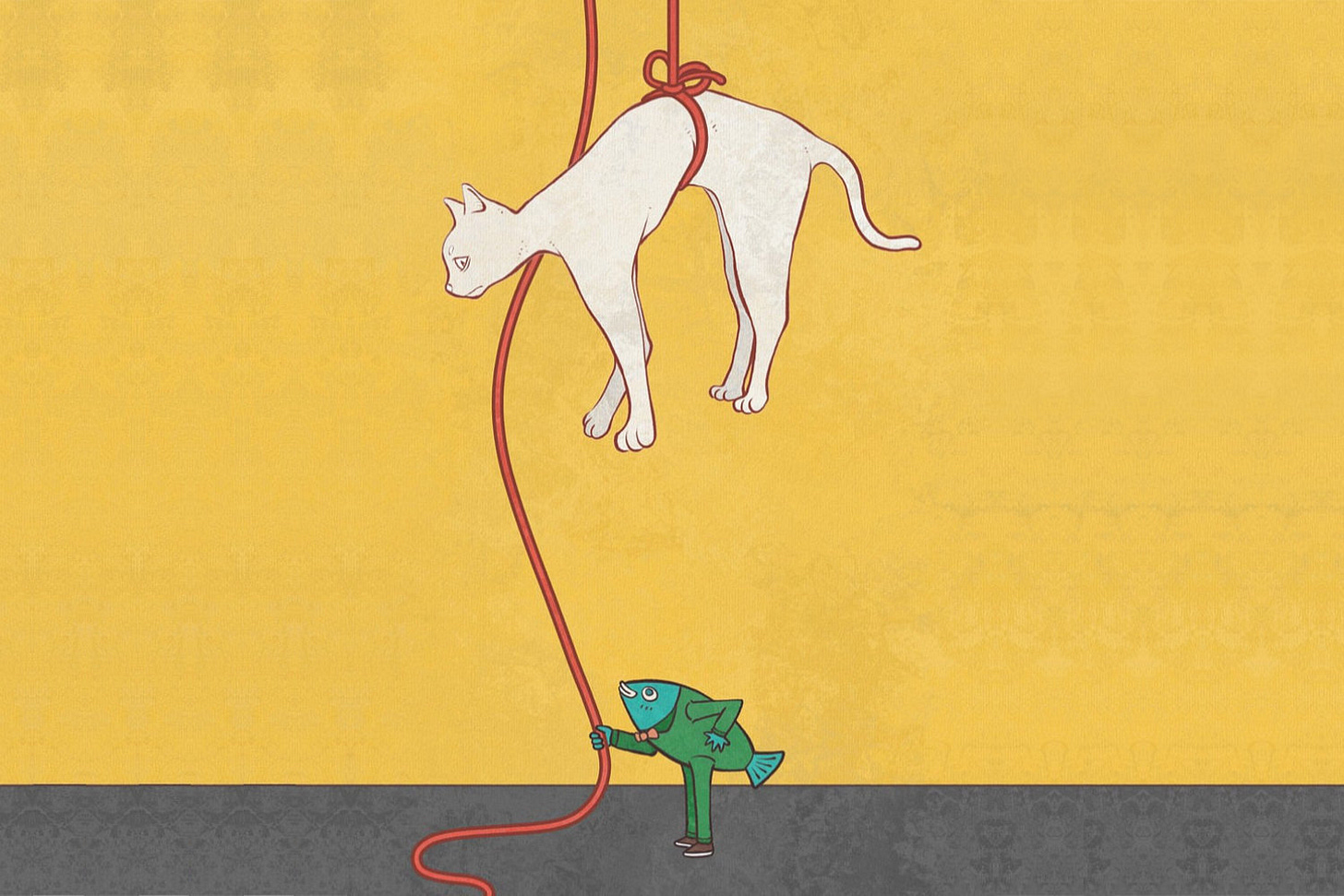

There’s always a cheaper fish

Hungry dogs quickly become fat cats. And are chased away by another hungry dogs. And repeat.

FDM / FFF technology seemed to have been „finished” for a long time. For several years, the only real innovations in this segment were related exclusively to new materials (which were becoming more and more „efficient”, „durable”, and „high-something”) and software (which was becoming increasingly easy to use, more intuitive, and automated).

Other than that — after the failure of consumer 3D printers, all OEM manufacturers switched to producing „industrial-grade machines”, the consequence of which was that 3D printing stopped being called 3D printing and became Additive Manufacturing.

Then 2022 happened, and Bambu Lab appeared…

And suddenly it turned out that FDM / FFF was not finished at all!

That something different could be done.

That it was possible to print much-much faster.

That it was possible to print much-much faster and in even better quality.

That all these cloud solutions are only now making sense — only now they are starting to be really useful.

Bambu Lab turned the desktop 3D printing industry upside down. It also shook the facades of the truly industrial FDM / FFF segment, which saw in the Chinese company a potential threat — for the first time since the early days of MakerBot Industries.

Everyone started chasing Bambu Lab, hastily changing the firmware in their 3D printers and accelerating speed, to never be left behind.

But nothing was the same anymore…

The market structure established a few years ago began to shake at its foundations — the previously unbeatable began to suffer their first significant defeats, and the fat cats started to see hunger in their eyes.

Bambu Lab is currently the best desktop 3D printer in the world.

And if you do not need to print really large objects from ABS, PC, PA — it is a real alternative to expensive and serious production systems.

But let me tell you three things:

This is not the first time we are dealing with this type of revolution.

All this has happened before — just differently.

It’s not the end — it’s just the beginning.

Bambu Lab is a sensation here and now. But in some time, someone new will come and do the same. “There’s always a bigger fish” — although in the case of 3D printing, a more appropriate saying is — “there’s always a cheaper fish”.

Revolution #1 — Adrian Bowyer

FDM technology was developed at the turn of the 80s and 90s of the 20th century by Scott and Lisa Crump, who founded Stratasys — one of the first companies in the then-emerging AM industry.

The technology was patented in 1989, and three years later commercialized in the form of the first 3D printer of this type named 3D Modeler. For the next several years, Stratasys’ position in this area was unchallenged due to patent protection.

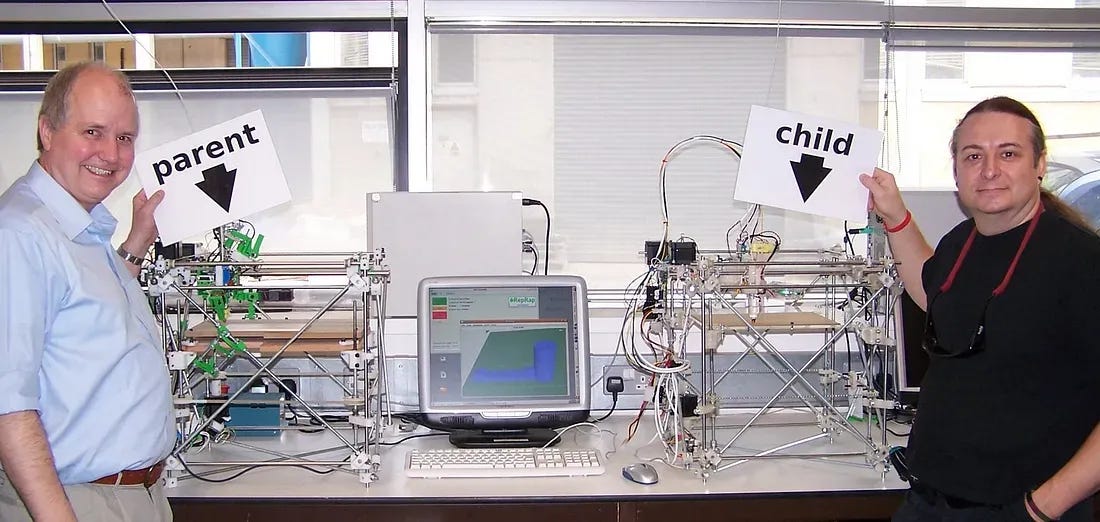

However, in 2005 — four years before the main patent for FDM expired, British academic lecturer Dr. Adrian Bowyer began work on a „self-replicating 3D printer” (RepRap), initiating the first revolution in 3D printing that led us to the flourishing of the entire industry.

Generally, the RepRap project was only a curiosity for Stratasys in the late 00s. The first 3D printers of this type were primitive, extremely difficult to use, supported a handful of materials, and to get one — you had to build it yourself.

It was an extremely niche product for a handful of enthusiasts — hobbyists and new technology amateurs, not posing any threat to the growing Stratasys.

Revolution #2 — Bre Pettis

Unfortunately for the company, a man named Bre Pettis took an interest in Bowyer’s project and, together with two engineer colleagues — Adam Mayer and Zach “Hoeken” Smith, created an alternative to Bowyer’s project — Cupcake CNC, which began to be offered in open sale as a DIY project.

Although still very primitive in operation, Cupcake was already a „ready-to-assemble” kit, not requiring independent trips to electronics stores and cost only $750, while Stratasys’ uPrint Personal Printer cost $14,900 [SIC!]. In 2010, an improved version of Cupcake — Thing-O-Matic appeared, and two years later the well-received MakerBot Replicator.

At the same time, increasing friction in company policy and identity began to occur between the founders of MakerBot — Zach Smith, Bre Pettis, and Mayer. Eventually, in April 2012, Smith was removed from the company, losing any contact with his recent partners.

When the main advocate of open-source disappeared, Pettis, Mayer, and representatives of the investment funds that had earlier invested $10 million in the company completely closed the sources of their 3D printer, releasing Replicator 2 in September 2012.

Replicator 2 delighted and excited users of 3D printers with its appearance and the class of solutions used in it, and on the other hand, it caused anger and outrage with the information about closing the sources and, in fact, betraying its initial ideals.

Nevertheless, it was the second revolution, which Stratasys could no longer ignore… Bre Pettis became an icon of global 3D printing, being compared to Steve Jobs.

In June 2013, Stratasys announced that it would acquire MakerBot Industries for $403 million, with the option of additional earn-out payments of an additional $201 million.

Although numerous imitators began to appear on the market — Ultimaker, Printrbot, LulzBot, Solidoodle, Robo3D, and Airwolf3D, none of them generated sales results like MakerBot and did not enjoy such popularity.

It seemed that Stratasys had stifled the FDM revolution in its infancy…

Revolution #3 — Zortrax

When everything seemed to be rearranged anew, in distant Poland, in the town of Olsztyn, a small startup with a strange name appeared — Zortrax S.A.

In mid-2013, the company raised $179,471 in funding on Kickstarter, delivering all ordered 3D printers ahead of the declared time — which at the time was quite an achievement.

On January 24, 2014, the 3D printing world was rocked by the sensational news that Zortrax would supply 5000 of its 3D printers to the Asian branch of DELL. Although two years later this information turned out to be a gigantic fake news, it opened the gates to the world of 3D printing for the company.

What’s more, it turned out that the Zortrax M200 was an amazing machine! Cheaper than the Replicator 2, it surpassed it in build quality, but above all, it offered 3D prints on a level comparable only to Stratasys industrial 3D printers.

Zortrax raised the bar very high for everyone. The 3D printer — no longer amateur, but truly desktop, had a closed ecosystem, excellent for the time proprietary software Z-SUITE and was above all very efficient, repeatable, and reliable. In 2014–2015, Zortrax was one of the most important players in the European 3D printing scene, and the rest were trying to catch up…

Unfortunately, the company made one terrible mistake. Instead of continuing to develop this excellent design, in 2015 it showed the world the next generation of its 3D printers — Zortrax Inventure.

The device, which was supposed to be a miniaturized Stratasys, with a tightly closed and heated build chamber, two printing heads, one of which dedicated only to support material, had a disastrous false start.

The first large batch of sold 3D printers returned entirely for service and its design problems were only solved in mid-2017. Unfortunately, by that time no one was waiting for Inventure anymore, as six months earlier the world was fascinated by another — much larger and equally affordable 3D printer…

Revolution #4 — Ultimaker

The Dutch company UltiMaker emerged in the European amateur 3D printing market in 2011, creating one of the iconic designs based on CoreXY kinematics.

The company’s 3D printers offered exceptional speed for that time and were supported by the CURA software, which gained significant popularity in the 3D printing community (and was eventually acquired by the company). In 2013, Ultimaker introduced an improved version of its debut 3D printer — Ultimaker 2, and in 2014, its enlarged version — Ultimaker 2 Extended.

Despite their considerable popularity, these were still 3D printers that straddled the line between amateur, consumer, and industrial 3D printing. That is, even though they were positioned as consumer 3D printers, they were often purchased by manufacturing enterprises and used in everyday project work or for creating simple tools or end-use parts.

However, it was not until the launch of Ultimaker 3 in the fall of 2016 that the Dutch company reached the pinnacle of popularity…

Ultimaker 3 was what Zortrax Inventure promised — a dual-head 3D printer, using a broad spectrum of engineering-grade materials, including polyamide and PCABS.

Thanks to the company’s CEO, Jos Burger, Ultimaker was able to enter the biggest industrial firms globally and establish cooperation in the area of 3D printing materials production with major chemical conglomerates like BASF, Clariant, DSM, Dupont, Henkel, Mitsubishi, Owens Corning, Sabic, among others.

The company began to perform exceptionally well in the American market, achieving in a short time what Zortrax never really managed — becoming a real alternative to the American MakerBot Industries.

Unfortunately, just as Zortrax made a mistake by taking on a project too ambitious for it, Ultimaker did the complete opposite — all subsequent 3D printers by the company were essentially the same…

Added functionalities, although interesting and useful, were not revolutionary in any way. The latest model — UltiMaker S7, resembled the practices of Electronic Arts, releasing a new version of EA Sports FIFA every year…

Revolution #5 — Josef Průša

Josef Průša is one of the icons of amateur 3D printing as well as the global open-source movement in general. The creator of “a better RepRap” — named Prusa Mendel, he moved from being one of the leading animators of the RepRap community to the owner of one of the largest companies in the global 3D printing market.

All this was thanks to very simple and extremely cheap 3D printers, which in terms of quality and efficiency started to successfully compete with much larger and more expensive ones like MakerBot, Ultimaker, or Zortrax.

The first truly groundbreaking point in Průša’s career was at the end of 2016 when there was a real boom for his 3D printers — Prusa i3 Mk2, which people massively bought for Christmas as a gift.

The company quickly raised a record amount of money, and PayPal — through which payments were made in it’s online store, froze about 1 million dollars, surprised by such a gigantic increase in the number of transactions.

Eventually, the matter was clarified (still leaving a bad taste in the mouth), and in 2017 Prusa Research became one of the leading players in the European market.

In the following years, more and more people bought Prusa 3D printers for home, appreciating its brilliant quality-to-price ratio. Over time, large manufacturing companies also started to be convinced by Prusa i3Mk2 and its subsequent iterations.

The economic calculation was simple — for the price of one Ultimaker 3, you could buy four equally good (though single-headed) Prusa i3s, and for the price of one Ultimaker S5, even six Czech 3D printers. Regardless of build quality, material availability, cloud service, etc., at the end of the day, you can print more parts on four or six 3D printers than on one.

Suddenly Prusa Research became for MakerBot and Ultimaker what previously MakerBot and Ultimaker were for Stratasys.

But the real revolution happened during the C19 pandemic when Josef Průša presented a protective face shield project for medics, and the whole world began to massively buy cheap 3D printers (mostly from Prusa) to produce them. And so, Prusa became a global giant.

And then the company made the same mistake as Zortrax a few years earlier… Although it had two highly rated 3D printers in its portfolio — Prusa i3 and Prusa MINI, it decided to tackle the industrial sector by presenting Prusa XL in 2021.

The machine was supposed to set new standards in affordable additive manufacturing, offering a whole array of amazing functionalities, but… the company did not deliver it on time. When it finally did (although deliveries of 3D printers ordered 2 years ago [SIC!] are still being fulfilled), everyone was already printing on BambuLab, and no one was particularly waiting for — or excited about — Prusa XL.

Revolution A.D. — Bambu Lab

Everything about this amazing 3D printer has already been written… The next models — Bambu Lab A1 and A1 Mini currently have only one goal — to slaughter Prusa Research with the same design, but higher build quality and an even lower price.

We will see in which direction the company will continue to move?

Historically, each of the aforementioned companies sooner or later made some strategic mistake that marked the beginning of its end (who remembers the triumphs of Zortrax from 2014–2015, or takes MakerBot seriously anymore, which has been reduced to the role of an educational 3D printer?).

Which path will Bambu Lab follow? Or maybe it will learn from the mistakes of its predecessors and we will do it differently for the first time ever…?

This article was originally published on LinkedIn on January 8, 2024. This is a reworked version.

I feel like Creality deserved a spot here 😄 Great article though